Understanding Radial Oil Seals Functions, Types, and Applications in Various Industries

Understanding Radial Oil Seals Functionality and Applications

Radial oil seals, commonly referred to as shaft seals or rotary seals, play a crucial role in the machinery and automotive industries. These components are designed to prevent the leakage of lubricants while protecting the internal components from contaminants such as dust, dirt, and moisture. By maintaining the integrity of the lubrication system, radial oil seals contribute significantly to the longevity and efficiency of equipment.

Structure and Design

A radial oil seal typically consists of three primary components the sealing element, the metal casing, and a spring. The sealing element is generally made from elastomeric materials like nitrile rubber, Viton, or silicone, which provide excellent sealing capabilities while ensuring flexibility. The metal casing offers structural support and stability, while the spring exerts continuous pressure on the sealing lip, ensuring a tight fit against the shaft.

The sealing lip of a radial oil seal is usually designed to fit snugly against the rotating shaft, creating a barrier that prevents oil from leaking while also blocking external contaminants. Depending on the application, the design can vary significantly, accommodating different shaft diameters, rotation speeds, and environmental conditions.

Working Principle

The functionality of radial oil seals is rooted in their ability to create a pressure differential. As the shaft rotates, the sealing lip of the oil seal hugs the surface of the shaft, maintaining contact and forming a tight barrier. This contact creates a labyrinth for the fluid, which helps to keep oil on the inside and contaminants on the outside.

When the machinery operates, varying pressure and temperature can affect the sealing performance. A properly designed radial oil seal can withstand these changes, providing a reliable solution for leakage prevention. However, it's essential to ensure that the seal is correctly installed and that the shaft surface is free from imperfections, as these factors can significantly impact its efficiency.

Applications

radial oil seals

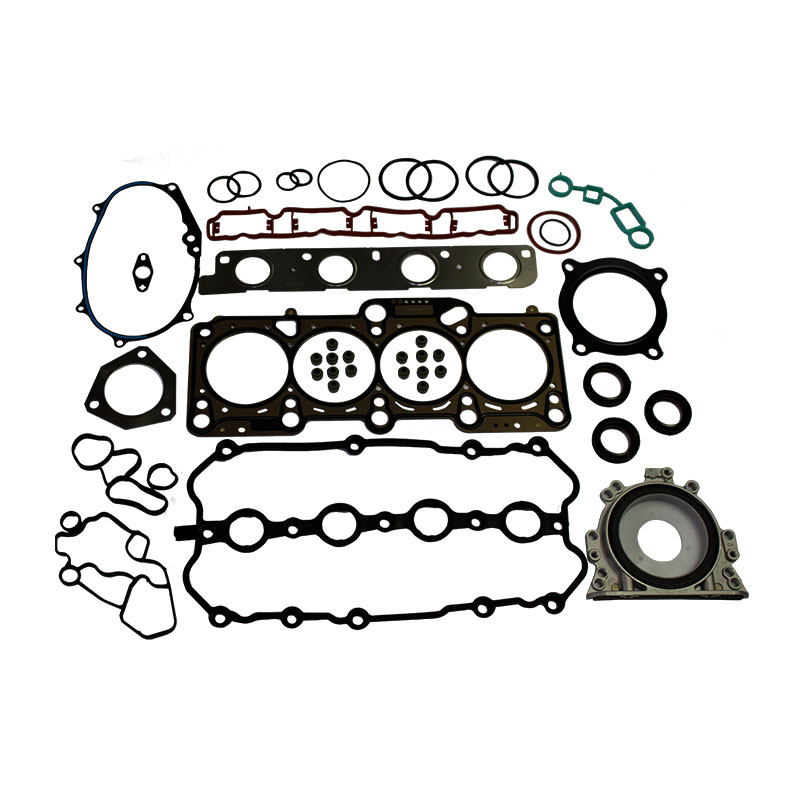

Radial oil seals are integral to a wide array of applications across several industries. In the automotive sector, they are used in engines, transmissions, wheel bearings, and differentials. Their primary function here is to maintain lubricant retention, ensuring optimal performance and reducing wear on engine components.

In industrial machinery, radial oil seals are commonly found in gearboxes, pumps, and hydraulic systems. They ensure that lubricants remain contained, preventing potential breakdowns and minimizing maintenance downtime. The aerospace sector also employs radial oil seals in turbine engines and landing gear systems, where failure of sealing components can lead to catastrophic consequences.

Beyond these industries, radial oil seals are used in household appliances, medical devices, and agricultural machinery, showcasing their versatility and vital role in modern machinery.

Challenges and Considerations

Despite their robustness, radial oil seals are not without challenges. Factors such as temperature extremes, chemical exposure, and environmental conditions can degrade the sealing materials, leading to leaks and operational failures. Therefore, selecting the right material and seal design for specific applications is critical.

Regular inspections and maintenance of seals can identify wear and tear before they lead to significant problems. In many cases, early detection of a failing seal can save substantial costs associated with equipment downtime and repairs.

Conclusion

Radial oil seals are indispensable components in various machinery and automotive applications. Their ability to prevent oil leakage and block contaminants is essential for maintaining the efficiency and longevity of equipment. As industries continue to evolve, the design and materials used for these seals will also advance, striving for better performance under diverse conditions. Understanding their functionality and application scope enables manufacturers and technicians to make informed decisions that enhance the operational life of their machinery. Thus, investing in high-quality radial oil seals is not just a matter of cost but an essential strategy for ensuring reliability and performance in mechanical systems.

-

Understanding Marine Bearings: The Key to Smooth Sailing and Safe Trailering

News May.08,2025

-

Understanding Critical Gaskets in Oil System Maintenance: From DT466 to 7.3 Powerstroke

News May.08,2025

-

Essential Guide to Marine Bearings and Trailer Hubs: Ensuring Safe Navigation and Transport

News May.08,2025

-

Essential Car Repair Kits Every Vehicle Owner Should Know About

News May.08,2025

-

Engine Restoration Essentials: Tools and Kits Every Mechanic Needs

News May.08,2025

-

Critical Marine Bearing Components: Ensuring Smooth Sailing and Safe Hauling

News May.08,2025

-

Understanding Automotive Gaskets: Keeping Your Engine and Transmission Leak-Free

News May.07,2025

Products categories