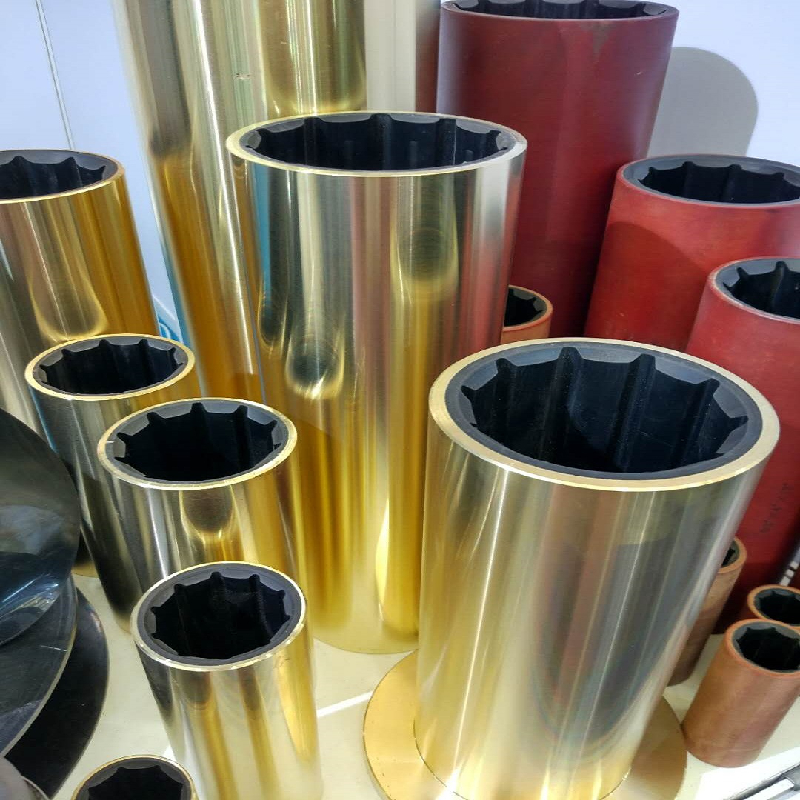

m14 aluminum crush washer

Understanding M14 Aluminum Crush Washers Importance, Applications, and Installation

When it comes to automotive and mechanical engineering, the terminology might seem complex, but some components are crucial for ensuring the efficiency and longevity of a system. One such component is the M14 aluminum crush washer. This small but significant part plays a vital role in creating a secure seal and preventing leaks in various applications, particularly in vehicles and machinery. In this article, we will discuss what M14 aluminum crush washers are, their applications, and how to install them.

What is an M14 Aluminum Crush Washer?

An M14 aluminum crush washer is a type of sealing washer specifically designed for M14 (metric 14mm) bolt sizes. Made from aluminum, these washers are characterized by their ability to deform (or crush) under pressure, allowing them to fill gaps and imperfections on the surface where they are installed. This deformation is critical in creating a leak-proof seal, making them indispensable in many mechanical applications.

Aluminum crush washers are preferred in various industries due to their lightweight nature, resistance to corrosion, and ability to withstand high temperatures. Also, aluminum is an excellent conductor of heat, making it suitable for applications in automotive engines and other machinery where heat dissipation is essential.

Applications of M14 Aluminum Crush Washers

M14 aluminum crush washers find their utility in several applications

1. Automotive Industry In vehicles, M14 aluminum crush washers are frequently used in oil drain plugs, oil filter housings, and transmission fluid pans. They effectively prevent leaks in critical components, ensuring that fluids remain contained and do not lead to hazardous spills or performance issues.

2. Aerospace Due, in part, to their lightweight properties, aluminum crush washers are also utilized in aerospace applications. They provide vital sealing solutions in fuel systems, hydraulic systems, and in various components where precise sealing is required to maintain pressure and avoid fluid loss.

3. Hydraulic Systems The hydraulic industry employs these washers, relying on them to seal connections in hydraulic lines, cylinders, and pumps. Proper sealing ensures optimal performance and prevents hydraulic fluid from leaking, which can be detrimental to the efficiency of hydraulic systems.

m14 aluminum crush washer

4. Marine Applications M14 aluminum crush washers can be found in marine engines and systems, where they help seal oil and fuel connections. Given the marine environment's exposure to saltwater, corrosion resistance is particularly important.

How to Install M14 Aluminum Crush Washers

Installing M14 aluminum crush washers is relatively straightforward, but proper technique is essential for ensuring a reliable seal. Here’s a step-by-step guide

1. Preparation Before installation, clean the surfaces of both the bolt and the receiving component. Remove any old washers or residue to ensure a flat, clean surface.

2. Select the Right Washer Ensure that the M14 aluminum crush washer is in good condition, free of cracks or deformations. An old, worn washer won't provide a reliable seal.

3. Position the Washer Place the crush washer onto the bolt or the area where it needs to be sealed. Ensure it is seated evenly against the surface.

4. Tightening Carefully start threading the bolt into the component. Hand-tighten initially to avoid cross-threading. Once it is hand-tight, use a torque wrench to tighten it to the manufacturer’s specified torque. This is crucial because over-tightening can cause the washer to crush too much or even break.

5. Final Inspection After installation, inspect the area for any signs of leakage. If any leaks are present, you may need to disassemble and check the installation.

Conclusion

M14 aluminum crush washers are more than just small metal discs; they are vital components that ensure the integrity of various systems in automotive, aerospace, and machinery applications. With their ability to create effective seals, they prevent leaks and contribute to the overall performance of the systems they serve. Understanding their importance and how to install them correctly can help maintain the efficiency and safety of engines and machinery, emphasizing the often-overlooked significance of such simple components in engineering and design.

-

Oil Drain Plug Washer Reusable Types

News Aug.22,2025

-

Oil Drain Plug Replacement Guide

News Aug.22,2025

-

Heavy Duty Seal Waterproof Features

News Aug.22,2025

-

Engine Oil Seals Installation Guide

News Aug.22,2025

-

Seal Oil for Sale High Temperature Grade

News Aug.22,2025

-

Cassette Seal Compact Design

News Aug.22,2025

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

Products categories