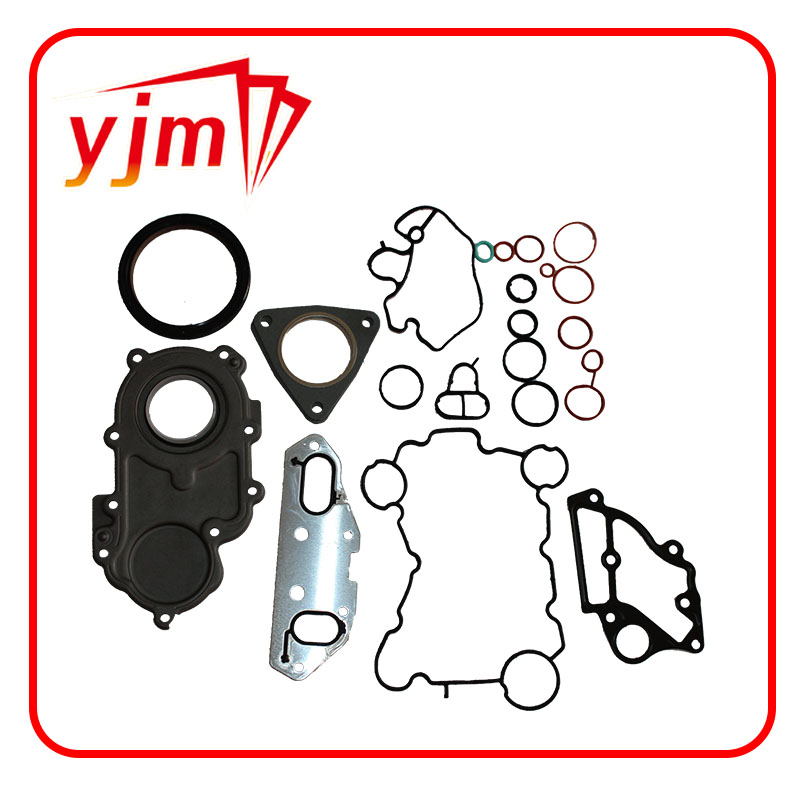

bonded seal kit

Understanding Bonded Seal Kits Essential Components for Sealing Applications

Bonded seal kits are essential components used in a variety of industries to ensure effective sealing and protection against leaks. These kits consist of rubber seals and metal washers, designed to work together to provide a reliable barrier against fluids, gases, and contaminants. Understanding the components and applications of bonded seal kits is crucial for anyone involved in manufacturing, automotive, construction, or maintenance industries.

Components of Bonded Seal Kits

A typical bonded seal kit includes two primary components the rubber part and the metal washer. The rubber seal, often made from materials such as nitrile, silicone, or fluorocarbon, is responsible for creating a tight seal. Its elasticity allows it to conform to different surfaces, ensuring that no gaps are present that could lead to leaks. The metal washer, usually made from steel or aluminum, provides support for the rubber seal and helps maintain the integrity of the assembly under various pressures.

The design of bonded seals allows them to withstand a range of temperatures and pressures, making them suitable for various applications. Depending on the materials used, some bonded seals can operate at extreme temperatures, while others are specifically designed to resist certain chemicals or fluids.

Applications of Bonded Seal Kits

bonded seal kit

The versatility of bonded seal kits makes them ideal for numerous applications. In the automotive industry, they are commonly used in engine components and hydraulic systems to prevent fluid leaks that could lead to serious failures. In construction, bonded seals are utilized in pipelines and heavy machinery to ensure that joints remain secure and free from leaks, safeguarding the integrity of the structures involved.

Moreover, these seal kits are vital in industries focused on manufacturing and processing, such as food and beverage, pharmaceuticals, and chemicals. In such environments, maintaining clean and leak-proof operations is critical to meet safety standards and avoid costly downtime.

Advantages of Using Bonded Seal Kits

One of the main advantages of bonded seal kits is their reliability. They provide a superior sealing solution compared to traditional gaskets, as they are less prone to compression set and deformation under pressure. This reliability translates into longer service life and reduced maintenance costs. Furthermore, the ease of installation of bonded seal kits can save valuable time during assembly or repair procedures.

Conclusion

In conclusion, bonded seal kits represent a crucial innovation in sealing technology. With their durable construction and wide array of applications, these kits play a pivotal role in maintaining efficiency and safety in various industries. Whether in automotive engineering, construction, or manufacturing, understanding and utilizing bonded seal kits is vital for anyone looking to mitigate leaks and enhance the performance of their systems. Investing in high-quality bonded seal kits is not just a choice; it’s an essential step towards ensuring operational excellence.

-

Understanding Polaris Front Differentials: Key Components for Off-Road Performance

News Jun.20,2025

-

Understanding Crankshaft Seals and Gaskets: Essential Components for Engine Longevity

News Jun.20,2025

-

Understanding Crankshaft Oil Seals: Vital Protection for Engine Performance

News Jun.20,2025

-

The Vital Role of Front and Rear Crankshaft Seals in Engine Protection

News Jun.20,2025

-

Rear Crankshaft Seals: Protecting Your Engine from the Back End

News Jun.20,2025

-

Crank Oil Seals: What They Do, How They Fail, and What They Cost

News Jun.20,2025

-

Understanding Oil Crush Washers: A Small Component with a Big Role in Vehicle Maintenance

News Jun.19,2025

Products categories