Understanding Wheel Oil Seals and Their Importance in Vehicle Maintenance

Understanding Wheel Oil Seals Importance, Types, and Maintenance

Oil seals, particularly wheel oil seals, play a crucial role in the proper functioning and longevity of various vehicles, including cars, trucks, and motorcycles. These seals are designed to prevent oil leakage, thereby maintaining proper lubrication for critical components, and ensuring optimal performance and efficiency.

What is a Wheel Oil Seal?

A wheel oil seal is a type of sealing device that is installed at the wheel assembly of a vehicle. It acts as a barrier to keep lubricating oil contained within the axle hub while preventing contaminants such as dirt, dust, and water from entering. By doing so, oil seals help maintain the necessary lubrication of bearings and other moving parts, reducing wear and tear, and ultimately prolonging the service life of the wheel assembly.

How Does a Wheel Oil Seal Work?

The functionality of a wheel oil seal hinges on its design. Typically composed of rubber or polymer, these seals feature a lip that makes contact with a rotating surface. As the wheel turns, the lip creates a dynamic seal that adjusts to any minor misalignment or movement, ensuring a tight fit. The sealing lip helps retain the oil under pressure and prevents it from leaking out. It also plays a pivotal role in keeping external contaminants at bay, which can otherwise lead to severe damage and costly repairs.

Types of Wheel Oil Seals

1. Single Lip Seals This is the most common type of oil seal used in automotive applications. They consist of a single sealing lip that contacts the rotating shaft or axle. Single lip seals are effective in keeping oil in and contaminants out, making them suitable for standard applications.

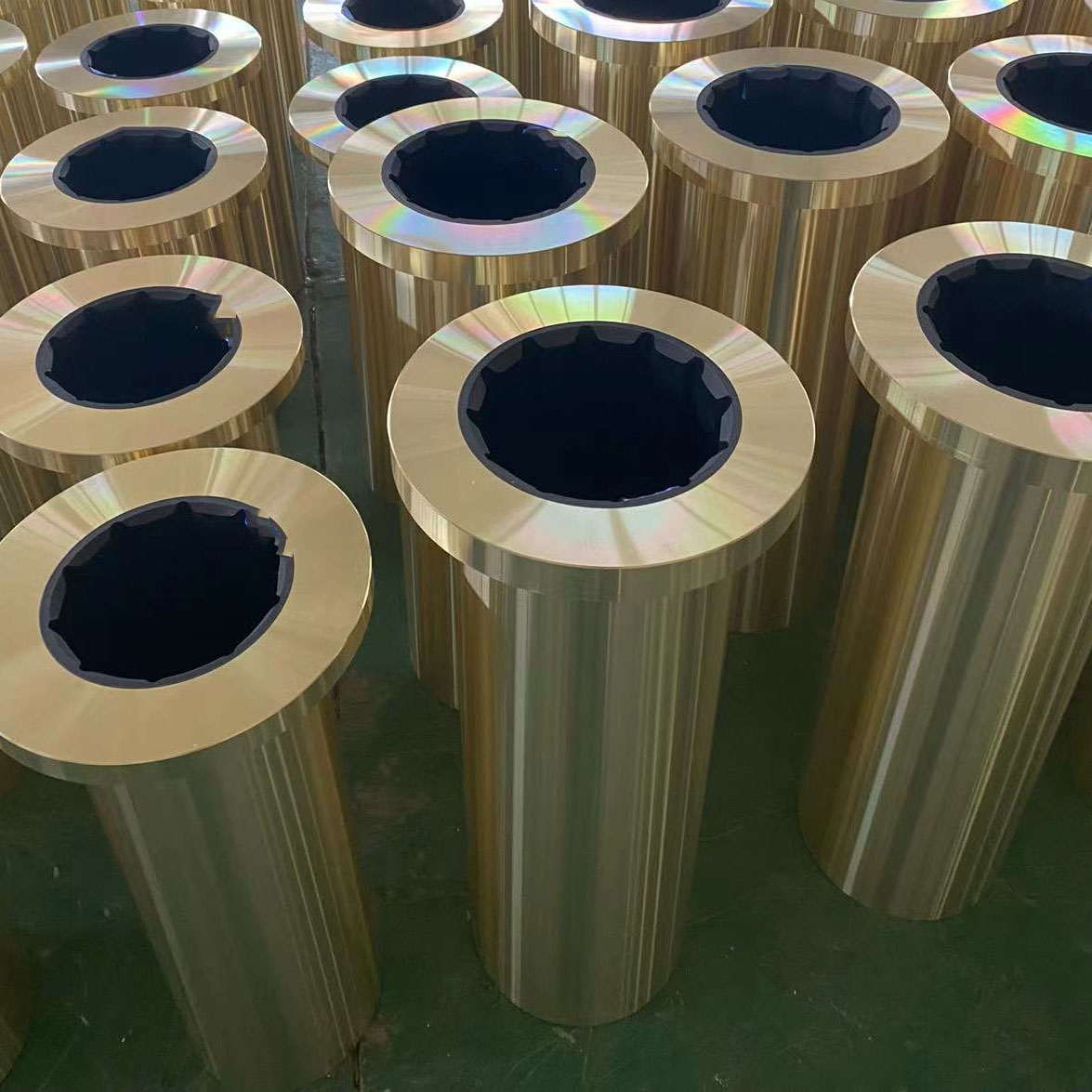

wheel oil seal

2. Double Lip Seals These seals have two sealing lips and are designed for situations that require higher protection. The additional lip provides an extra layer of defense against contaminants and can be advantageous in harsh environments, such as off-road conditions.

3. Spring-Loaded Seals This type incorporates a spring mechanism that applies constant pressure to the sealing lip against the shaft. This design helps maintain a better seal over time and compensates for wear and tear, making them ideal for applications with significant movement or vibration.

Importance of Regular Maintenance

Wheel oil seals, like any other component of a vehicle, require regular inspection and maintenance. Over time, seals can wear out due to exposure to heat, oil, and environmental conditions. Signs of a failing oil seal may include leakage of oil around the wheels, excessive noise from the wheel bearings, or vibrations during driving.

To ensure optimal performance, it is advisable to periodically check the seals during routine vehicle maintenance. If there are any signs of wear or damage, replacing the oil seals promptly is crucial. Ignoring such issues can lead to more severe problems, including wheel bearing failure, resulting in more costly repairs.

Conclusion

Wheel oil seals are essential components that significantly influence the performance and longevity of a vehicle. Understanding their function, types, and maintenance requirements can help vehicle owners take proactive steps to prevent leaks and damages. Regular inspections and timely replacements not only enhance vehicle reliability but also contribute to safer driving experiences. By prioritizing the well-being of wheel oil seals, drivers can enjoy peace of mind knowing that their vehicle operates smoothly and efficiently.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories