Exploring the Features and Benefits of TC Oil Seals for Enhanced Performance

Understanding TC Oil Seals Their Importance and Functionality

Oil seals, often referred to as grease seals or oil retaining seals, play a crucial role in a variety of machinery and automotive applications. Among the various types of oil seals, TC oil seals are particularly noteworthy due to their design and functionality. In this article, we will delve deeply into what TC oil seals are, how they function, and why they are essential in different industries.

What is a TC Oil Seal?

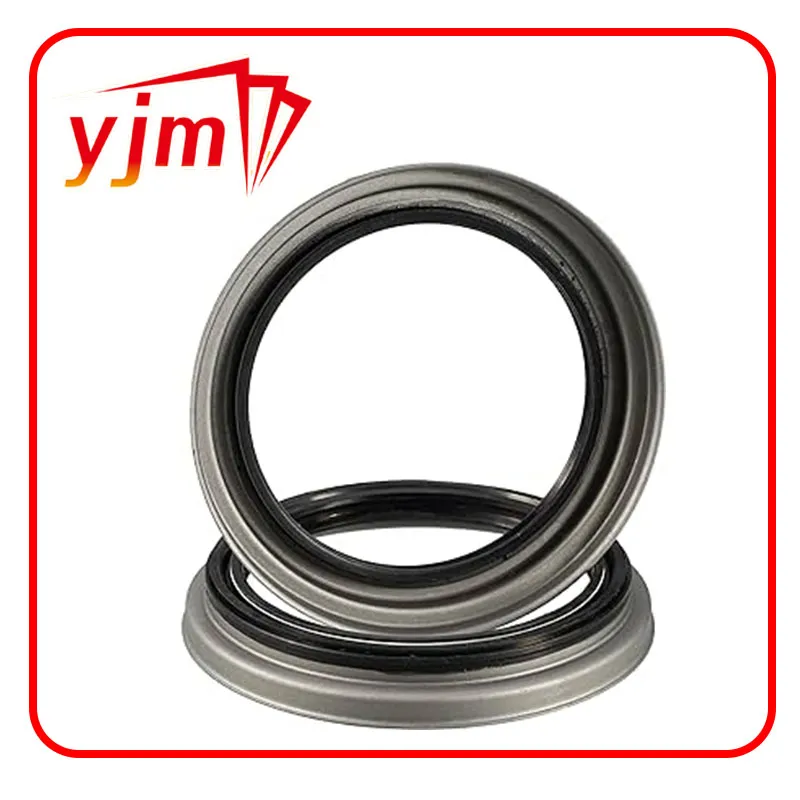

TC oil seals are a specific type of rotary shaft seal designed to prevent the leakage of oil and other lubricants from machinery components. The TC designation refers to the design features incorporated into these seals “T” stands for a metallic casing and a lip that retains fluid, while “C” indicates the presence of a secondary seal or contact lip that enhances sealing performance. Typically, TC oil seals consist of a rubber body with a metal reinforcement, which provides durability and resilience under varying operating conditions.

How TC Oil Seals Work

The functioning of TC oil seals is based on the concepts of creating a barrier against liquids, especially lubricating oils. The seal is installed around a rotating shaft. As the shaft spins, the edge of the TC oil seal presses against its surface. This contact creates a tight seal that prevents oil from leaking out of the machinery while simultaneously keeping contaminants such as dirt, dust, and moisture from entering the internal components.

In practical applications, TC oil seals are engineered to withstand considerable pressure and temperature fluctuations, making them ideal for use in engines, gearboxes, and pumps. The unique design of the TC oil seal, including the use of high-quality elastomers and a precision-engineered metal casing, ensures longevity and consistent performance even in harsh environments.

Applications of TC Oil Seals

TC oil seals are widely used across various industries, owing to their reliability and effectiveness. Here are some common applications

1. Automotive Industry TC oil seals are extensively used in vehicles, encompassing engines, transmissions, and differentials. They help maintain the integrity of lubricants and protect crucial components from wear and tear.

2. Industrial Machinery Manufacturing equipment often requires TC oil seals to contain lubricants and prevent external contamination, ensuring the smooth operation of moving parts.

tc oil seal

3. Agricultural Equipment In agriculture, where machinery is subjected to demanding conditions, TC oil seals are vital for maintaining operational efficiency and reducing maintenance costs.

4. Aerospace and Aviation Aircraft engines and systems use TC oil seals to manage lubricants and protect against environmental challenges, ensuring safety and reliability during flight operations.

Benefits of Using TC Oil Seals

The benefits of incorporating TC oil seals in industrial and automotive applications cannot be overstated. Here are some key advantages

- Leak Prevention TC oil seals effectively prevent the leakage of lubricants, which helps maintain optimal lubrication levels, prolonging the life of the machinery.

- Contaminant Protection By creating a barrier against dust, dirt, and other foreign particles, TC oil seals protect internal components, reducing wear and enhancing reliability.

- Temperature Resistance Designed to function effectively under extreme temperatures, TC oil seals are capable of preventing seal failure in diverse operating environments.

- Reduced Maintenance Costs By minimizing leaks and protecting components, TC oil seals can lead to lower maintenance costs and extend the lifespan of machinery.

Conclusion

In conclusion, TC oil seals are indispensable components in both automotive and industrial applications. Their unique design and functionality offer significant advantages, including effective fluid retention and protection against contaminants. As machinery becomes more sophisticated, the importance of reliable seals like TC oil seals will continue to grow, ensuring the smooth and efficient operation of countless systems. Understanding and utilizing the right type of oil seal can contribute significantly to enhanced performance and longevity of equipment, making them a critical component of modern engineering.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories