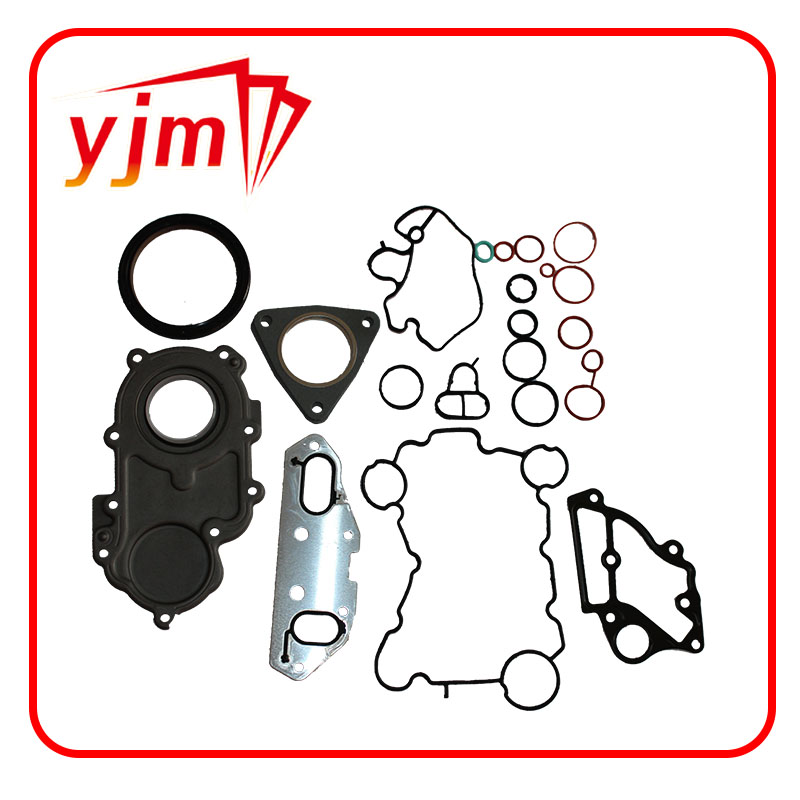

Sure, here's a short phrase similar to m14 sump plug with around 10 words in English M14 sump plug adapter fitting.

This integration allows for predictive maintenance alerts and optimization of engine performance based on driving conditions This integration allows for predictive maintenance alerts and optimization of engine performance based on driving conditions

This integration allows for predictive maintenance alerts and optimization of engine performance based on driving conditions This integration allows for predictive maintenance alerts and optimization of engine performance based on driving conditions m14 sump plug.

Moreover, the design of the plug has become increasingly aerodynamic to minimize drag and potential oil foaming, which can occur when air gets into the system. Some manufacturers have also started using sump plugs as a point for adding additives directly into the oil stream, enhancing engine longevity and reducing wear.

The environmental impact of the M14 sump plug should not be overlooked. As regulations demand lower emissions and higher fuel efficiency, the plug's ability to maintain a tight seal is crucial for reducing oil consumption and subsequent exhaust emissions. A small leak can lead to significant quantities of oil vaporizing and bypassing the combustion chamber, contributing to pollution.

In conclusion, the M14 sump plug represents a microcosm of automotive engineering progress. From a simple seal to a high-tech component, it has adapted to the demands of evolving engines while maintaining its primary function. Its development illustrates how even the smallest parts play a vital role in the overall health and efficiency of our vehicles. As we look towards the future of transportation, it will be fascinating to see how this unassuming yet essential piece of hardware continues to evolve alongside the ever-changing landscape of automotive technology.

m14 sump plug.

Moreover, the design of the plug has become increasingly aerodynamic to minimize drag and potential oil foaming, which can occur when air gets into the system. Some manufacturers have also started using sump plugs as a point for adding additives directly into the oil stream, enhancing engine longevity and reducing wear.

The environmental impact of the M14 sump plug should not be overlooked. As regulations demand lower emissions and higher fuel efficiency, the plug's ability to maintain a tight seal is crucial for reducing oil consumption and subsequent exhaust emissions. A small leak can lead to significant quantities of oil vaporizing and bypassing the combustion chamber, contributing to pollution.

In conclusion, the M14 sump plug represents a microcosm of automotive engineering progress. From a simple seal to a high-tech component, it has adapted to the demands of evolving engines while maintaining its primary function. Its development illustrates how even the smallest parts play a vital role in the overall health and efficiency of our vehicles. As we look towards the future of transportation, it will be fascinating to see how this unassuming yet essential piece of hardware continues to evolve alongside the ever-changing landscape of automotive technology. -

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories