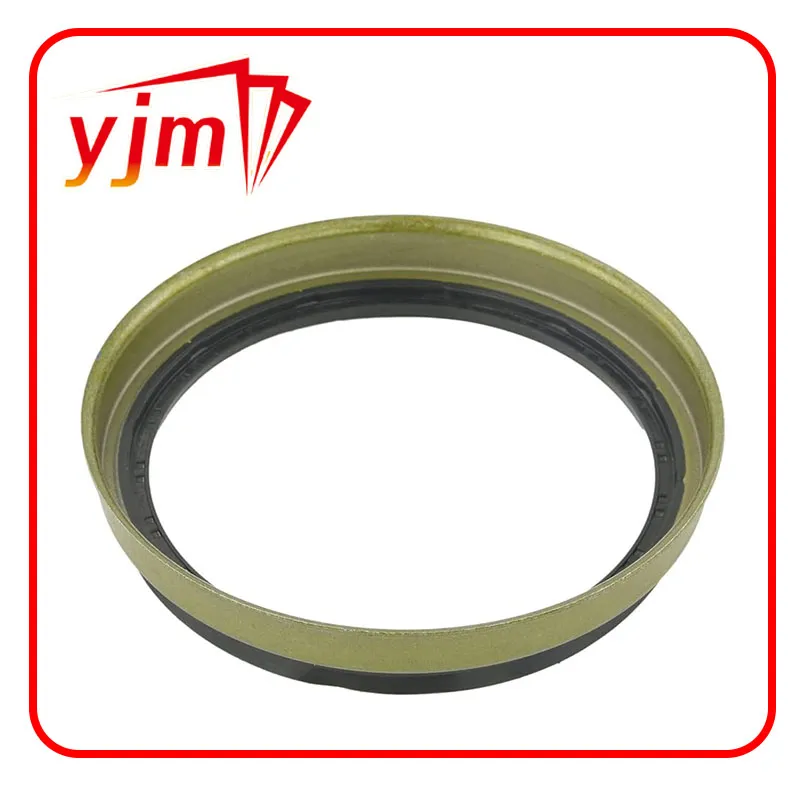

shift seal

Understanding the Importance of Shift Seals in Modern Manufacturing

In the rapidly evolving world of manufacturing, efficiency and precision are paramount. Among the myriad components that contribute to optimal performance in machinery and production processes, the shift seal emerges as a critical element. Understanding the function and significance of shift seals can illuminate their role in enhancing operational efficiency and prolonging the lifespan of machines.

What is a Shift Seal?

A shift seal is a type of sealing device primarily used in mechanical systems to prevent the leakage of fluids, such as oil or hydraulic fluids, during the shifting process of gears, axles, or other moving parts. This component is often found in automotive transmissions, industrial machinery, and various equipment requiring fluid transfer and pressure management. The primary function of a shift seal is to maintain the integrity of the system it serves by keeping necessary fluids contained, thus preventing contamination and loss of performance.

The Role of Shift Seals in Machinery

In any machine where movement and fluid dynamics are at play, shift seals play a pivotal role. They help ensure that the mechanical parts can shift smoothly without external interference or fluid loss. When gears or levers shift positions, they generate motion that can cause friction, heat, and potential wear and tear. Shift seals are designed to withstand these forces while maintaining an airtight and watertight environment.

Without the proper functioning of shift seals, manufacturers face several challenges

1. Fluid Loss Leakage can lead to significant drops in fluid levels, ultimately causing machines to operate less efficiently or even fail. 2. Contamination Foreign particles entering the system can cause damage to sensitive components, leading to costly repairs and downtime.

3. Increased Maintenance Costs Regularly replacing worn or damaged seals can increase the operational costs of machinery, which can significantly cut into profit margins.

shift seal

4. Environmental Impact Leakage of fluids can have detrimental effects on the environment, urging manufacturers to adopt more effective sealing solutions to comply with regulations.

Innovations in Shift Seal Technology

As technology progresses, so too does the design and manufacturing of shift seals. Modern shift seals are made using advanced materials such as elastomers and thermoplastics that provide enhanced durability and resistance against wear, temperature, and chemical exposure. The incorporation of new engineering techniques allows designers to create seals that maintain their integrity under extreme operating conditions.

Moreover, the adoption of computer-aided design (CAD) and simulation software in the seal development process enables manufacturers to optimize seal geometry and performance. These innovations lead to improved functionality and longer service life for shift seals, ultimately benefiting the entire manufacturing process.

The Future of Shift Seals

Looking ahead, the future of shift seals is promising. With the rise of smart manufacturing and the integration of the Internet of Things (IoT), predictive maintenance technologies are being developed that could monitor the condition of seals in real-time. Sensors can detect wear and initiate timely replacements or repairs before significant failures occur, thus enhancing overall operational efficiency.

Furthermore, as industries increasingly focus on sustainability, there is a push for eco-friendly materials and designs that minimize waste and maximize recyclability. This evolution not only aligns with global environmental goals but also caters to the growing consumer demand for sustainable practices.

Conclusion

Shift seals may seem like minor components in the grand scheme of manufacturing, but their importance cannot be overstated. They help maintain fluid integrity, enhance machine performance, and ensure operational efficiency, all while contributing to cost savings and environmental protection. As manufacturing continues to evolve, the role and technology surrounding shift seals will undoubtedly advance, addressing the challenges of modern production and shaping the future of the industry. As we increase our understanding and improve our technologies surrounding these crucial components, we can expect even greater innovations that will propel manufacturing into a new era of efficiency and sustainability.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories