Understanding the Function and Benefits of Retainer Oil Seals in Machinery

Understanding Retainer Oil Seals Importance, Design, and Applications

In the world of mechanical engineering, ensuring the integrity of fluid containment systems is essential. Among various components designed for this purpose, retainer oil seals play a pivotal role. This article delves into the importance, structure, and applications of retainer oil seals, shedding light on why they are indispensable in numerous industries.

What is a Retainer Oil Seal?

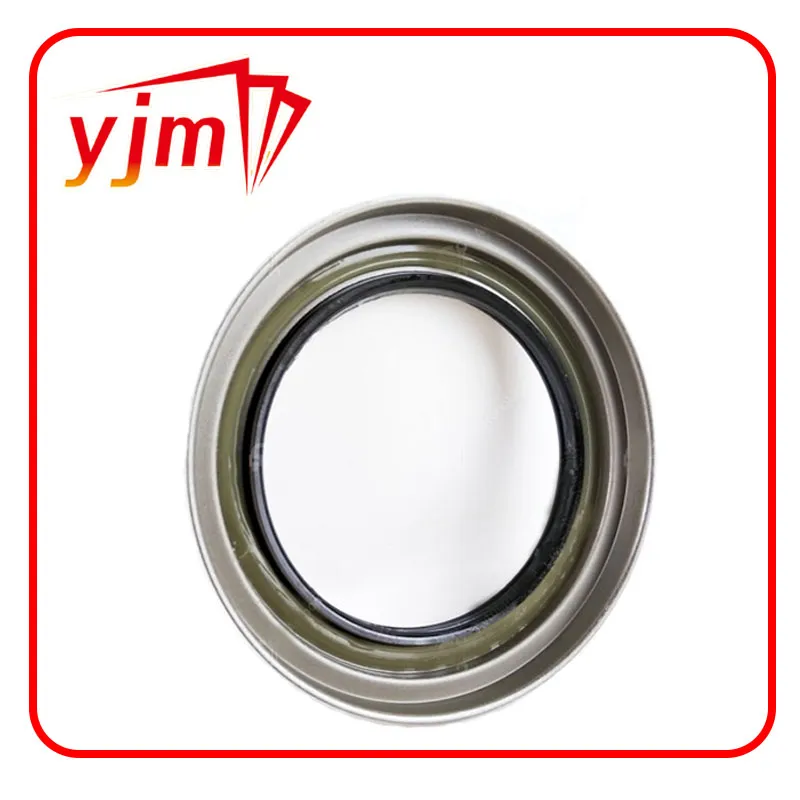

A retainer oil seal, often referred to simply as an oil seal, is a mechanical device used to seal the junction between stationary and moving components, effectively preventing the leakage of lubricating fluids—primarily oil. It is designed to retain oil or other lubricants within machinery while simultaneously keeping contaminants like dust, dirt, and moisture from entering the system.

The Importance of Retainer Oil Seals

1. Prevent Fluid Leakage One of the primary functions of retainer oil seals is to prevent oil from leaking out of machinery. Oil leaks can lead to significant operational issues, including reduced lubrication, increased friction, and the potential for overheating, which can cause machinery failures.

2. Protect Against Contamination By sealing the interface between components, these seals keep harmful substances out of the lubrication system. Contaminants can degrade oil quality and damage internal components, leading to costly repairs and increased downtime.

3. Enhance Equipment Longevity Properly functioning retainer oil seals contribute to the overall reliability and lifespan of machinery. By maintaining proper lubrication and protecting against contamination, these seals help ensure that machines operate smoothly over extended periods.

Design Features of Retainer Oil Seals

Retainer oil seals consist of several crucial components

- Seal Body Typically made from durable materials like rubber or polymer, the seal body forms the main part of the oil seal, providing flexibility and durability. - Metal Reinforcement Many oil seals incorporate a metal retainer that provides structural support, ensuring the seal maintains its shape under pressure and during operation.

retainer oil seal

- Dynamic and Static Sealing Lips The dynamic lip contacts the rotating shaft, creating a sealing effect that minimizes leakage. The static lip seals against the housing, providing a barrier to external contaminants.

- Dust Lip Some designs include an additional dust lip, which further protects against dirt and debris, enhancing the seal's effectiveness and lifespan.

Applications of Retainer Oil Seals

Retainer oil seals are utilized across various industries, including

1. Automotive In vehicles, oil seals are found in engines, transmissions, and differentials. They help retain engine oil and transmission fluid, ensuring that components function correctly.

2. Industrial Machinery Manufacturing equipment often uses oil seals to protect hydraulic systems and gearboxes, preventing costly oil leaks that can disrupt operations.

3. Aerospace In aviation applications, oil seals play a critical role in maintaining hydraulic systems and ensuring the reliability of various aircraft components.

4. Marine Boats and other maritime vehicles use oil seals to prevent seawater from entering the engine compartment, thereby protecting machinery and improving performance.

5. Home Appliances Various household machines, from washing machines to refrigerators, utilize retainer oil seals to enhance durability and prevent leaks that can cause damage or inefficiency.

Conclusion

Retainer oil seals may appear to be small, unassuming components, but their impact on mechanical systems is significant. By effectively preventing fluid leaks and protecting machinery from contaminants, they facilitate the reliable operation of a wide range of equipment across various industries. Understanding the importance and functionality of retainer oil seals not only helps engineers in the selection and maintenance of these components but also underscores their pivotal role in ensuring operational efficiency and longevity in machinery. As technology evolves and demands increase, the design and application of retainer oil seals will continue to play a vital role in modern engineering solutions.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories