Understanding the Functionality and Operation of Oil Seals in Mechanical Applications

Understanding the Working Principle of Oil Seals

Oil seals are critical components designed to prevent the leakage of oil and other fluids in mechanical systems. These seals ensure the integrity of machinery by blocking lubricant loss and protecting the bearings and other components from contaminants such as dirt, dust, and moisture. Understanding the working principle of oil seals is essential for effective maintenance and operation of various mechanical systems, from automotive engines to industrial machinery.

Basic Structure of Oil Seals

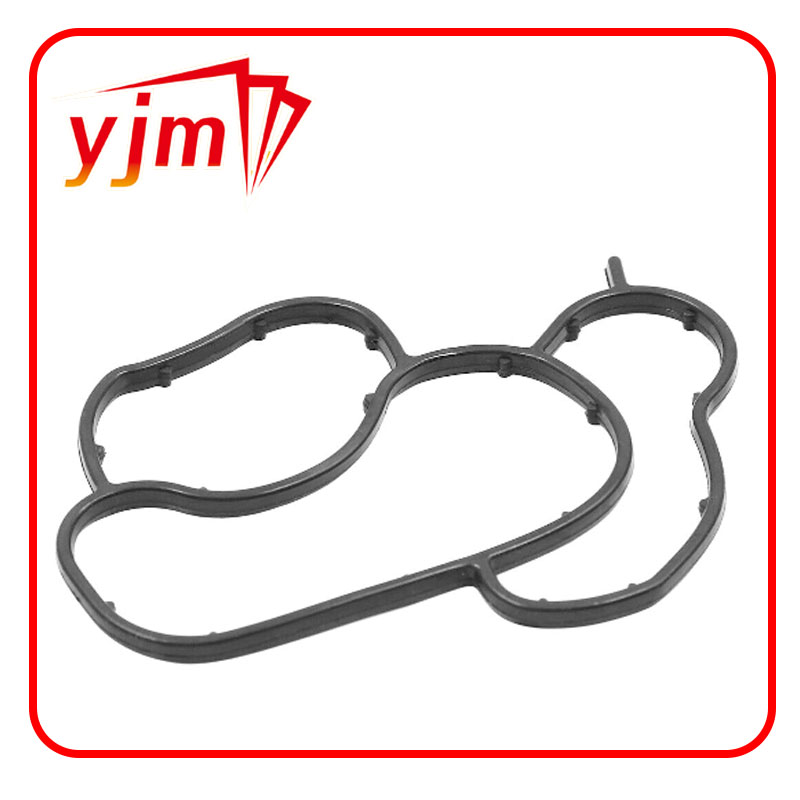

An oil seal typically consists of a circular elastomeric (rubber-like) material, which is often reinforced with fabric for added strength and durability. The main components of an oil seal include the sealing lip, the body, and the outer casing. The sealing lip is the most critical part, as it provides direct contact with the rotating shaft. This lip creates a tight barrier that minimizes fluid leakage while allowing for the necessary movement of the shaft.

In addition, oil seals may also have a spring mechanism, such as a garter spring, designed to apply constant pressure against the sealing lip. This feature helps maintain a proper seal by ensuring that the lip remains in tight contact with the shaft, adapting to any variances in the shaft’s diameter or surface.

Working Principle

The working principle of oil seals is relatively simple yet effective. When installed around a rotating shaft, the sealing lip makes contact with the shaft, creating a barrier that prevents oil from escaping the system. The friction between the shaft and the sealing lip generates a small amount of heat, which is typically manageable. However, the design of oil seals aims to keep this heat to a minimum to ensure that the seal does not degrade over time.

The elastomeric material of the seal is crucial; it is engineered to provide both flexibility and durability. When the shaft rotates, the lip of the seal flexes to accommodate the movement, maintaining pressure against the shaft. This flexibility allows the oil seal to create a dynamic seal that can withstand the varying temperatures and pressures within the system.

oil seal working principle

Types of Oil Seals

There are several types of oil seals, each designed for specific applications and environments. Common types include single-lip seals and double-lip seals. Single-lip seals consist of one sealing lip and are commonly used in applications where dirt and contamination are not significant concerns. On the other hand, double-lip seals contain two lips, providing enhanced protection against external contaminants and making them ideal for more demanding environments.

Furthermore, oil seals can be categorized based on their construction materials. While most oil seals are made from synthetic rubber, options like silicone or polyurethane may be utilized for specific applications requiring resistance to extreme temperatures or chemicals. The choice of material affects the performance, longevity, and suitability of the oil seal for the intended operation.

Applications

The applications of oil seals are vast and span across numerous industries. In automotive engineering, oil seals are crucial for preventing oil leaks in engines and drivetrain components. In industrial settings, they safeguard machinery like pumps and gearboxes, ensuring operational efficiency. Even in household appliances like washing machines, oil seals play a vital role in maintaining performance and preventing leaks.

Conclusion

Oil seals are essential for ensuring the reliable operation of various mechanical systems by preventing oil leakage and protecting internal components from contaminants. Their design and working principles allow them to adapt to movements while maintaining a secure seal. Understanding the intricacies of oil seals and their applications is vital for proper maintenance, which in turn enhances the efficiency and longevity of machinery. Consequently, selecting the right type of oil seal for a specific application can significantly impact overall performance.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories