oil seal 25x42x7

Understanding the 25x42x7 Oil Seal Applications, Importance, and Maintenance

Oil seals are essential components in various mechanical systems. Among the different sizes and specifications available, the 25x42x7 oil seal holds particular significance in numerous applications. This article will delve into the features, applications, importance, and maintenance of the 25x42x7 oil seal.

What is an Oil Seal?

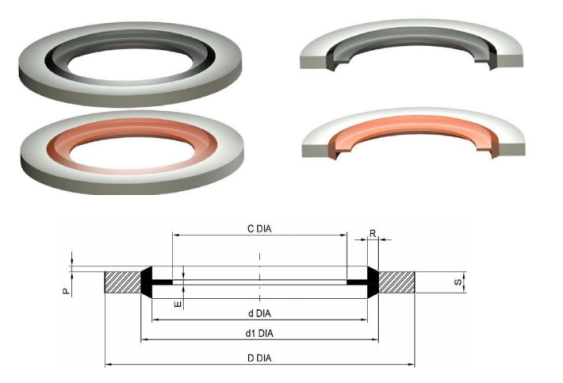

An oil seal, also known as a grease seal, is a mechanical component designed to retain lubricants and prevent contaminants from entering an assembly. These seals are typically made from materials such as rubber, silicone, or fluoropolymer, and are designed to withstand different temperatures, pressures, and chemical environments. The numbers associated with an oil seal, such as 25x42x7, refer to the seal's dimensions the first number (25) is the inner diameter in millimeters, the second number (42) is the outer diameter in millimeters, and the third number (7) refers to the seal's thickness.

Applications of 25x42x7 Oil Seal

The 25x42x7 oil seal is versatile and widely used in various industries. Some of its primary applications include

1. Automotive Industry In vehicles, these oil seals are commonly used in engines, transmissions, and differentials to prevent oil leaks. The 25x42x7 size fits many automotive components, providing a reliable seal that maintains the lubricant's integrity.

2. Industrial Machinery Many industrial machines, such as pumps, motors, and gearboxes, require effective sealing solutions. The 25x42x7 oil seal can be found in such applications, ensuring efficient operation and extending the lifespan of the machinery by preventing contamination by dirt and dust.

3. Agricultural Equipment Tractors and other agricultural machinery also utilize these seals. They protect crucial components from mud, water, and other environmental factors, thereby maintaining performance and reducing wear and tear.

4. Marine Applications In marine environments, where equipment is exposed to harsh conditions, the 25x42x7 oil seal is used to ensure that critical machinery remains effective and free from moisture and saltwater intrusion.

oil seal 25x42x7

Importance of the 25x42x7 Oil Seal

The importance of the 25x42x7 oil seal cannot be overstated. It plays a crucial role in prolonging the life of mechanical components by minimizing friction and preventing lubricant leakage. By keeping contaminants out of lubricated spaces, the seal also reduces the risk of equipment failure, which can lead to costly repairs and downtime. Furthermore, these seals contribute to overall efficiency, helping machinery operate smoothly and reliably.

Maintenance and Replacement

To ensure the effective functioning of a 25x42x7 oil seal, regular maintenance is essential. This includes

1. Inspection Periodically inspecting the oil seal for signs of wear, such as cracks or deformation, is crucial. A damaged seal may lead to lubricant leakage and contamination.

2. Proper Installation When replacing an oil seal, correct installation is key. Damage can occur if the seal is improperly installed, leading to failure and potential equipment damage.

3. Monitoring Fluid Levels Keeping an eye on fluid levels can help detect potential leaks early, allowing for timely replacement of worn seals.

4. Environmental Considerations Being aware of the environmental conditions where the machinery operates can guide the selection of appropriate seal materials to ensure durability and performance.

In conclusion, the 25x42x7 oil seal is a vital component across various industries, ensuring the smooth operation of machinery and preventing costly failures. Understanding its applications, importance, and maintenance requirements can lead to better performance and longevity of mechanical systems. By recognizing the value of such seals, businesses can enhance their operational efficiency and reduce maintenance costs.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories