m14 drain plug washer

Understanding the M14 Drain Plug Washer Importance and Applications

When it comes to maintaining vehicles or machinery, small components like drain plug washers often go unnoticed. However, these seemingly minor parts play a crucial role in ensuring the efficiency and longevity of systems that rely on fluids, such as engines, hydraulic systems, and various machinery. Among the various types of washers available, the M14 drain plug washer stands out due to its specific applications and importance in fluid systems.

What is an M14 Drain Plug Washer?

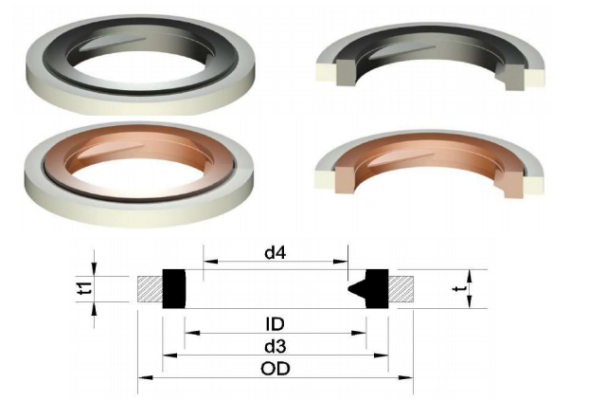

The term M14 refers to the metric size of the washer, indicating a 14mm diameter, which is commonly used in conjunction with M14 drain plugs. These washers are often made of materials such as rubber, copper, or aluminum, each offering unique properties suitable for different applications. The primary function of the M14 drain plug washer is to create a seal that prevents fluid leakage when the drain plug is secured.

The Role of the Washer in Fluid Sealing

When engines or machinery are drained of oil or other fluids, ensuring a tight seal upon reassembly is critical. The M14 washer fulfills this need by compressing slightly when the drain plug is tightened, forming a barrier against leaks. This sealing function helps maintain optimal fluid levels, which is essential for the efficient operation of mechanical systems. Failure to use a proper washer or using a damaged one can lead to fluid leaks, causing potential damage to the equipment and creating hazardous conditions.

Applications of the M14 Drain Plug Washer

The M14 drain plug washer is widely used across various applications, particularly in automotive and industrial settings. Here are some common scenarios where these washers come into play

1. Automobiles In vehicles, the M14 drain plug washer is typically found in oil pans, helping to seal the drain plug after an oil change. Regularly replacing the washer during oil changes can prevent leaks caused by old or damaged washers.

m14 drain plug washer

2. Motorcycles Similar to cars, motorcycles use M14 washers to seal the oil drain plug. Due to the high vibrations associated with motorcycle engines, ensuring a secure seal is even more critical to prevent oil leakage.

3. Heavy Machinery In construction and agricultural equipment, M14 washers are used in hydraulic systems and engines. Keeping these washers in good condition helps to maintain the integrity of hydraulic lines and engine oil systems.

4. Marine Applications Boats and other marine vessels also utilize M14 drain plug washers in their engine systems. Given the exposure to water and varying environmental conditions, reliable sealing is vital to prevent water ingress.

Choosing the Right Washer

Selecting the right M14 drain plug washer involves considering the material and the specific requirements of the application. For example, rubber washers are often used for their excellent sealing properties and resistance to corrosion. In contrast, metal washers, such as those made from copper or aluminum, may be better suited for high-temperature applications due to their durability.

Maintenance and Replacement

Regular inspection of the drain plug washer is essential for effective maintenance. A visual inspection can reveal signs of wear, cracking, or deformation, which indicate that it is time for replacement. It is advisable to replace the washer each time the drain plug is removed to ensure a proper seal during reassembly. Additionally, using the correct torque specifications when tightening the drain plug can further prolong the life of the washer and prevent leaks.

Conclusion

The M14 drain plug washer may be a small component, but its significance in mechanical systems cannot be underestimated. By understanding its function and applications, users can make informed decisions about maintenance and replacement, ensuring that their machinery and vehicles operate efficiently and reliably. Whether in automotive, industrial, or marine contexts, the M14 drain plug washer is a vital part of preventing leaks and maintaining fluid integrity in countless systems.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories