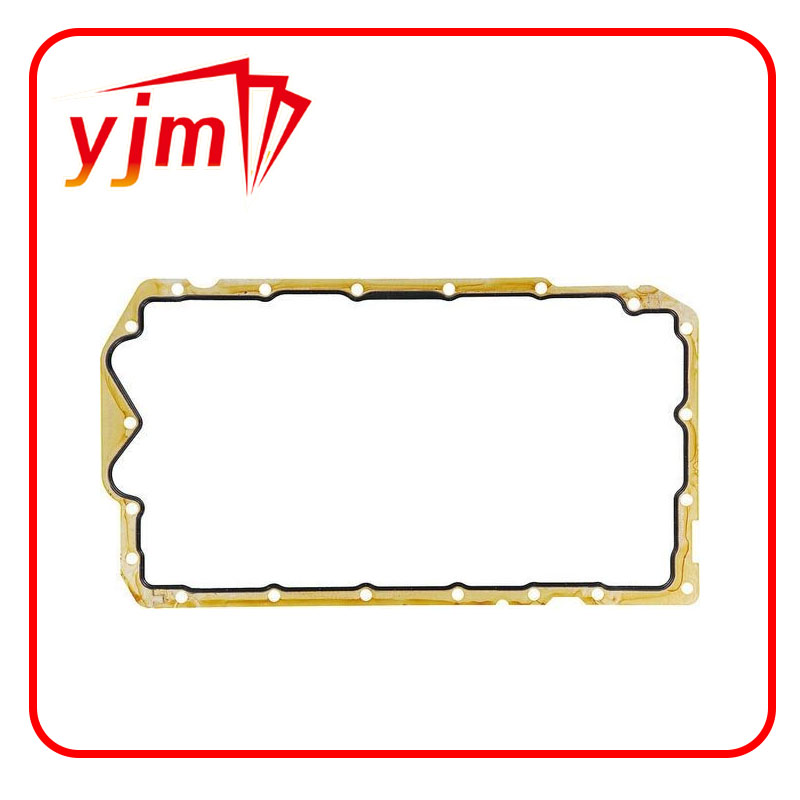

Similar Design for Flat Ring Gasket with Enhanced Sealing Performance and Durability

The Importance of Flat Ring Gaskets in Industrial Applications

In the world of engineering and manufacturing, the quest for effective sealing solutions is paramount. One component that often plays a critical role in this domain is the flat ring gasket. While they may seem like simple objects, flat ring gaskets are essential in ensuring the integrity and efficiency of a wide range of applications.

What is a Flat Ring Gasket?

At its core, a flat ring gasket is a sealing device typically made from materials such as rubber, silicone, metal, or composite materials. They are designed to be placed between two surfaces, providing a barrier that prevents the leakage of fluids or gases. The unique design of flat ring gaskets allows them to accommodate various flange types and shapes, making them versatile for numerous applications, from automotive to aerospace and beyond.

Applications of Flat Ring Gaskets

Flat ring gaskets are widely used in many industries, including

1. Automotive In vehicles, flat ring gaskets are used in engine components, fuel systems, and exhaust systems. They help maintain pressure and prevent the escape of crucial fluids like oil and coolant, contributing to the vehicle's overall performance and reliability.

2. Aerospace The aerospace industry relies on flat ring gaskets to ensure safe and efficient operation of aircraft. These gaskets are used in fuel tanks, hydraulic systems, and airframe structures to prevent leaks that could jeopardize flight safety.

3. Construction In construction, flat ring gaskets play a vital role in plumbing systems and HVAC installations. They provide reliable sealing in pipes and ducts, ensuring the efficient transport of water, gas, and air without leakage.

4. Oil and Gas The oil and gas sector employs flat ring gaskets in drilling equipment and pipelines. Given the extreme pressures and temperatures in these environments, high-quality gaskets are essential for safety and operational efficiency.

The Advantages of Flat Ring Gaskets

Flat ring gaskets offer several advantages that make them a popular choice across various industries

flat ring gasket

- Versatility Their flat design allows them to be used in multiple applications with different flange configurations. This adaptability reduces the need for specialized sealing solutions.

- Cost-Effectiveness Flat ring gaskets are generally affordable, making them a cost-effective choice for manufacturers and contractors looking to maintain their systems without breaking the bank.

- Ease of Installation These gaskets are straightforward to install, allowing for quick assembly and maintenance in industrial settings. This simplicity can lead to reduced downtime in operations.

- Effective Sealing When properly installed, flat ring gaskets provide a tight seal that can withstand significant pressure changes, making them reliable for critical applications.

Material Considerations

The material used in flat ring gaskets can significantly affect their performance. Common materials include

- Rubber Often used for low-pressure applications due to its flexibility and ability to conform to irregular surfaces.

- Metal Metallic gaskets are preferred for high-temperature and high-pressure applications, providing robust sealing capabilities.

- Composite Materials These offer a balance between flexibility and strength, making them suitable for a variety of settings, particularly in corrosive environments.

Conclusion

In conclusion, flat ring gaskets are more than just simple sealing devices; they are integral components in ensuring the safety, efficiency, and reliability of numerous industrial applications. With a wide range of materials and designs available, they can be tailored to meet specific needs across various sectors. As industries continue to evolve and demand tighter seals in high-pressure environments, the role of flat ring gaskets will undoubtedly remain critical. Being aware of their significance can help engineers and manufacturers make informed decisions, ultimately leading to improved performance and safety in their operations.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories