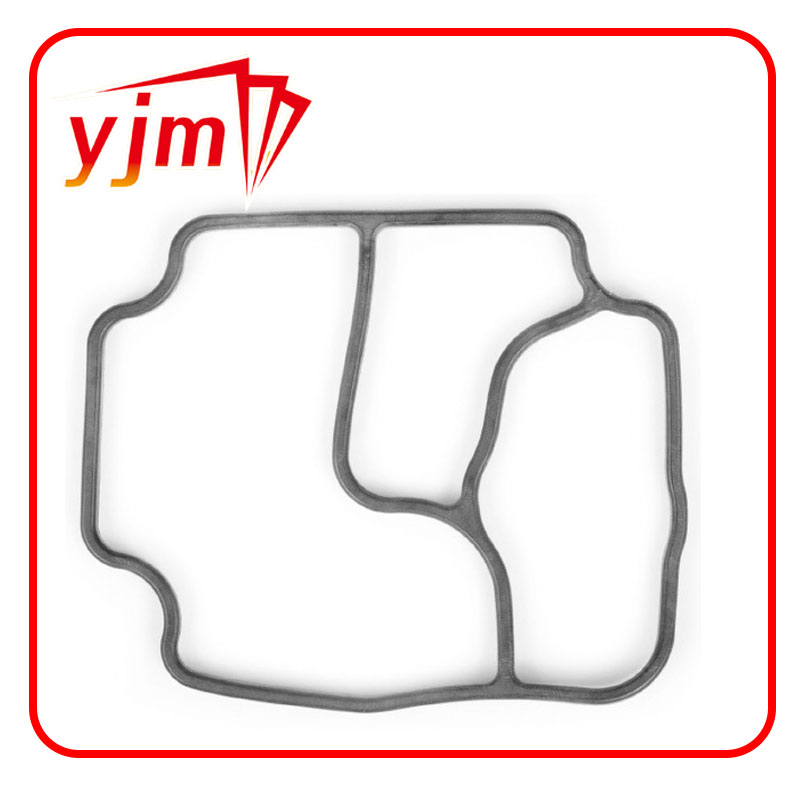

flat gasket material

Understanding Flat Gasket Materials A Comprehensive Guide

Flat gaskets are an essential component in various industrial applications, particularly in machinery and automotive systems. Their primary function is to create a seal between two surfaces, preventing leakage of fluids or gases and ensuring the efficient operation of systems. Selecting the appropriate gasket material is critical for achieving optimal performance. This article aims to provide a thorough understanding of flat gasket materials, their types, applications, and considerations for choosing the right one.

Types of Flat Gasket Materials

1. Rubber Rubber gaskets are popular for their flexibility and ability to form a tight seal. They can withstand moderate pressures and temperatures, making them suitable for applications like plumbing and HVAC systems. Common rubber materials include neoprene, nitrile, and silicone. Each type offers different resistance to chemicals and temperature ranges.

2. Non-Asbestos Compressible Gasket Materials These gaskets are designed to replace traditional asbestos materials, providing a safe option without compromising performance. They are composed of a variety of fibers, fillers, and binders, making them suitable for high-temperature and high-pressure applications. Industries such as automotive and petrochemicals frequently use non-asbestos gaskets.

3. Metal Metal gaskets are typically used in high-temperature and high-pressure environments. Common metals used include stainless steel, copper, and aluminum. Metal gaskets are often used in the automotive and aerospace industries due to their ability to withstand extreme conditions. They are durable and can be re-used, which helps reduce long-term costs.

4. PTFE (Polytetrafluoroethylene) PTFE gaskets are known for their excellent chemical resistance and ability to withstand high temperatures. They are non-stick and can be used in a wide range of applications, including food processing, pharmaceuticals, and chemical processing. PTFE’s unique properties make it a preferred choice for sealing aggressive chemicals.

5. Fiber Gaskets These gaskets are made from a composite of materials, including cellulose and other fibers. Fiber gaskets are lightweight and can compress easily, ensuring a tight seal under different conditions. They are often used in water and gas applications, providing an effective seal while being cost-efficient.

Applications of Flat Gasket Materials

Flat gaskets are used in a variety of industries, including

flat gasket material

- Automotive In engines, transmissions, and exhaust systems, flat gaskets play a critical role in preventing oil and coolant leaks. - Chemical Processing The resistance to corrosive substances makes flat gaskets vital in chemical plants, where maintaining a tight seal is essential to prevent hazardous leaks. - Food and Beverage In food processing systems, gaskets must meet stringent sanitary standards and withstand cleaning chemicals and temperatures. - Aerospace Flat gaskets in aircraft engines must endure extreme conditions, requiring materials that can handle high pressures and temperature fluctuations.

Choosing the Right Flat Gasket Material

Selecting the appropriate flat gasket material involves several considerations

1. Temperature and Pressure Ratings Understand the operational environment to select a material that can withstand the temperature and pressure conditions without failing.

2. Chemical Compatibility Evaluate the fluids or gases the gasket will encounter. Ensure the material selected has adequate resistance to prevent degradation over time.

3. Environmental Factors Consider external conditions such as moisture, UV exposure, or industrial contaminants that may affect the gasket’s performance.

4. Application Needs Identify the specific requirements of the application, such as compressibility, flexibility, or rigidity. Different materials will perform better based on these needs.

5. Cost-Effectiveness While high-performance materials may come at a premium, evaluate the long-term costs associated with leaks or failures due to inadequate sealing.

Conclusion

Flat gasket materials play a vital role in ensuring the efficient operation of a wide range of systems across various industries. Understanding the different types of materials, their applications, and the factors influencing material selection is essential for achieving optimal performance. By selecting the right flat gasket material tailored to the specific application, industries can enhance reliability, improve safety, and reduce maintenance costs. Therefore, thorough consideration and analysis of gasket materials are critical in maintaining operational efficiency.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories