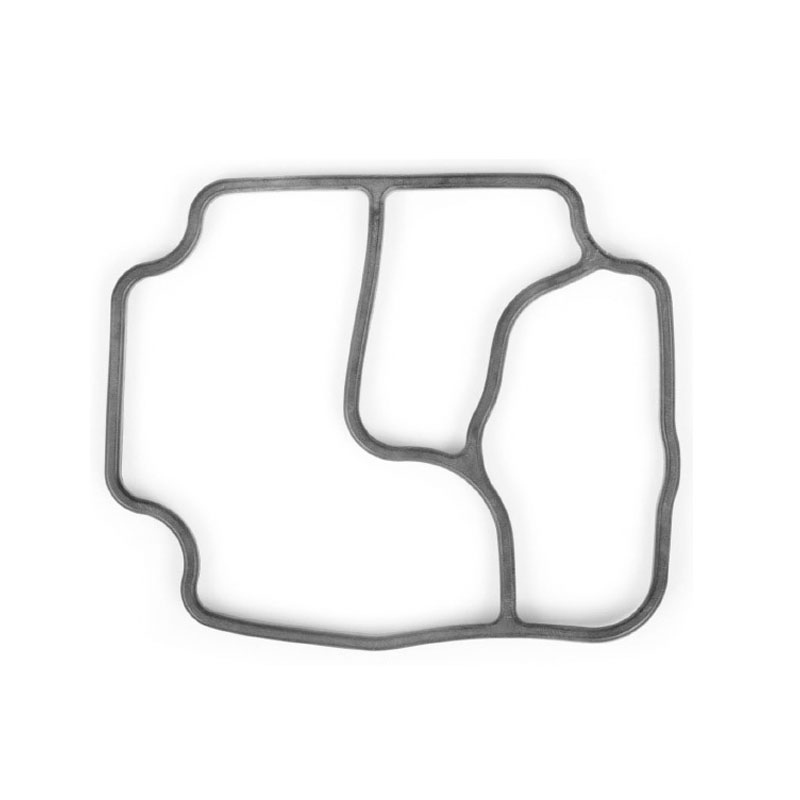

fkm oil seal

Understanding FKM Oil Seals Performance, Applications, and Benefits

FKM oil seals, also known as fluorocarbon oil seals, are integral components in various mechanical assemblies, designed to prevent the leakage of lubricants and fluids while protecting against environmental contaminants. The development of FKM material, often recognized through its commercial names like Viton, has revolutionized sealing technology, offering superior performance compared to traditional materials.

What is FKM?

FKM, a type of fluorocarbon elastomer, is synthesized from a combination of fluorine, carbon, and hydrogen atoms. This unique molecular structure imparts exceptional properties, making FKM an ideal choice for oil seals in demanding environments. These properties include excellent resistance to high temperatures, chemicals, and harsh environmental conditions, along with good mechanical stability and aging resistance.

Advantages of FKM Oil Seals

1. Temperature Resistance FKM materials can withstand a temperature range from -20°C to 200°C (about -4°F to 392°F), making them suitable for both hot and cold applications. This capability is critical in industries where equipment operates under fluctuating temperatures.

2. Chemical Resistance FKM oil seals exhibit outstanding resistance to oils, fuels, and various chemicals, including acids and bases. This property allows them to be used in automotive, aerospace, and industrial applications, where exposure to aggressive substances is common.

3. Durability The inherent durability of FKM materials reduces the risk of wear and tear over time, resulting in extended service life. This longevity leads to reduced maintenance costs and less frequent replacement of seals.

4. Flexibility and Compression Set Resistance FKM oil seals maintain their flexibility and shape under prolonged compression. This resistance to deformation ensures a better sealing performance, preventing leaks and ensuring operational efficiency.

5. Versatility Available in various shapes and sizes, FKM seals can be tailored to meet specific requirements across multiple industries, including automotive, food processing, marine, and industrial machinery.

fkm oil seal

Applications of FKM Oil Seals

1. Automotive Industry FKM oil seals play a vital role in automotive engines, gearboxes, and axle assemblies. Their chemical resistance ensures reliable sealing of motor oils and transmission fluids, while their temperature tolerance protects against engine heat.

2. Aerospace In aerospace applications, where components are subjected to extreme temperatures and pressures, FKM seals are essential for maintaining the integrity of hydraulic systems and fuel systems.

3. Industrial Machinery Equipment used in heavy industries often experiences exposure to harsh chemicals and extreme conditions. FKM oil seals provide the necessary protection against fluid leakage and contamination, ensuring efficient operation and safety.

4. Food and Beverage Industry The food processing industry requires seals that can withstand specific hygienic standards. FKM seals certified for food contact ensure that they do not contaminate consumables, while maintaining performance against oils and cleaning agents.

Choosing the Right FKM Oil Seal

Selecting the appropriate FKM oil seal involves considering factors such as the operating temperature, chemical exposure, and the types of fluids being sealed. It’s essential to consult with manufacturers or industry experts who can provide guidance on the best specifications for your application.

Conclusion

FKM oil seals represent a significant advancement in sealing technology, offering unmatched performance in demanding applications. Their resistance to heat and chemicals, combined with their durability and flexibility, make them indispensable in various industries. As technology continues to evolve, FKM oil seals will remain at the forefront of engineering innovations, ensuring efficient and safe operation across a multitude of applications. Whether in automotive, aerospace, or industrial machinery, the reliability and efficiency of FKM oil seals contribute significantly to the longevity and performance of critical equipment.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories