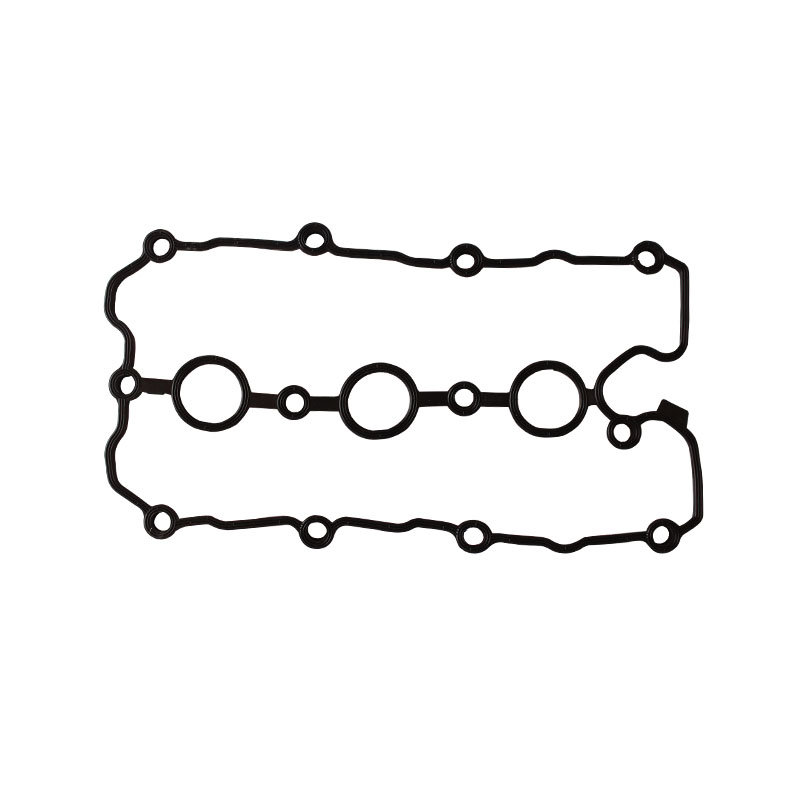

double lip seal

Understanding Double Lip Seals Design, Function, and Applications

Double lip seals are increasingly recognized in various industrial applications for their efficiency in providing a reliable barrier against leakage, contamination, and lubricant loss. These seals are designed with two distinct lips, which enhance their performance compared to traditional single lip seals. The primary function of double lip seals is to prevent the ingress of dirt, dust, and moisture while also retaining lubricants within machinery components. This dual protection is crucial in prolonging the lifespan and efficiency of mechanical systems.

The design of a double lip seal typically incorporates two sealing elements that work in tandem. The first lip faces the external environment, effectively keeping out contaminants. The second lip is positioned towards the inner side, assisting in retaining the lubricant. This configuration not only improves sealing effectiveness but also minimizes wear on the shaft or the rotating element it protects. The materials used in manufacturing these seals often include elastomers like nitrile, fluorocarbon, and silicone, chosen for their resilience against temperature fluctuations and chemical exposure.

double lip seal

One of the significant advantages of double lip seals is their versatility. They are used in numerous applications, ranging from automotive to aerospace, and from industrial machinery to household appliances. For instance, in automotive applications, double lip seals are commonly found in wheel bearings, where they safeguard against dirt ingress and maintain the lubricant integrity under high-speed conditions. Similarly, in hydraulic cylinders, these seals ensure the systems operate smoothly by containing hydraulic fluids and preventing contamination.

Moreover, the performance of double lip seals can be enhanced through various design modifications, such as the addition of a spring mechanism. This feature allows the seal to maintain an optimal contact force against the shaft, compensating for wear and ensuring a tighter fit over time. As a result, manufacturers can achieve greater operational efficiency and reduce maintenance costs.

In conclusion, double lip seals play a crucial role in enhancing the performance and reliability of various mechanical systems. Their innovative design, which includes dual sealing lips, offers superior protection against leaks and contamination, making them a preferred choice in many industries. As technology continues to advance, the demand for efficient sealing solutions like double lip seals is expected to grow, driving further innovations in seal design and application.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories