din 3760 type a

Understanding DIN 3760 Type A A Comprehensive Guide

DIN standards are essential for ensuring quality and consistency across various industries, particularly in manufacturing and engineering. One such standard, DIN 3760 Type A, is critical in the context of flanges for pipes and fittings. In this article, we will explore the specifications of DIN 3760 Type A, its applications, and its significance in industrial settings.

What is DIN 3760?

DIN 3760 is a standard developed by the German Institute for Standardization (Deutsches Institut für Normung e.V.), which outlines the design and dimensions of flanges used primarily in pipeline systems. Flanges are crucial components that serve as connectors between two sections of pipe or between a pipe and a valve, pump, or other equipment. The standard provides specifications that ensure compatibility and safety in fluid transport systems.

Type A Flanges

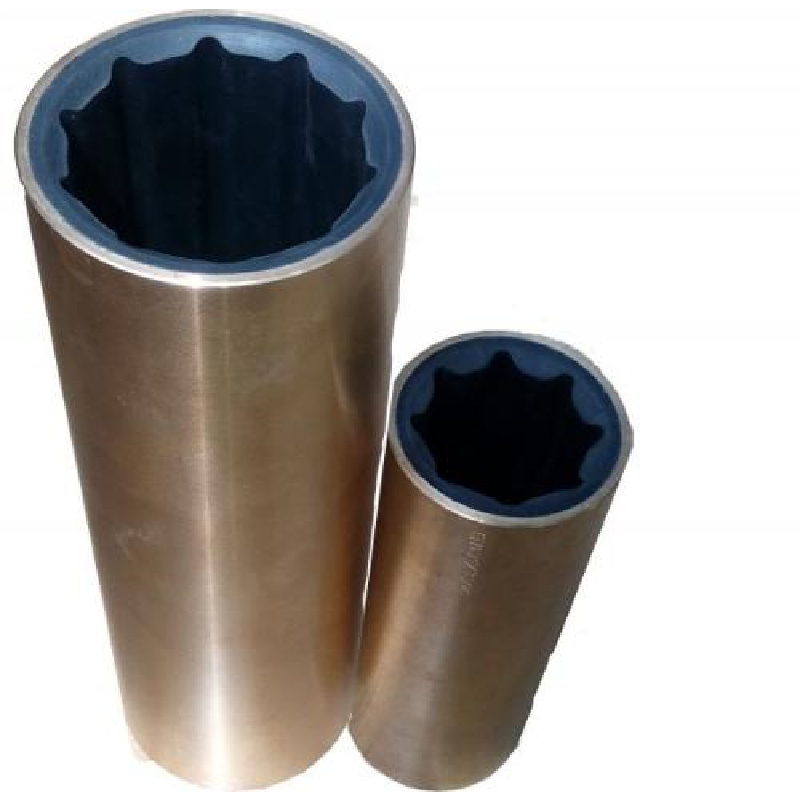

DIN 3760 Type A specifically refers to a particular design of flanges under the DIN 3760 standard. These flanges are characterized by their rigid construction and the way they interface with other piping components. Type A flanges are typically used with metric screws and are frequently made from materials such as stainless steel, carbon steel, or other alloys, ensuring they can withstand the pressures and environments they encounter.

Key Specifications

DIN 3760 Type A flanges come with specific dimensions that determine their suitability for various applications. Some of the key specifications include

- Diameter The size of the flange can vary widely, making it essential to choose the right diameter for the intended application. - Thickness The thickness of Type A flanges is standardized to provide adequate strength and reliability under pressure. - Bolt Hole Pattern The arrangement and size of the bolt holes are critical for ensuring secure fastening to prevent leaks.

din 3760 type a

The standard also stipulates material properties that help ensure durability and corrosion resistance, vital for flanges used in environments with chemicals, high temperatures, or high pressures.

Applications of DIN 3760 Type A Flanges

DIN 3760 Type A flanges are utilized across various sectors, including

1. Chemical Processing They often connect pipes transporting corrosive substances. 2. Water Treatment Plants Their sturdiness makes them ideal for handling water and wastewater systems. 3. Oil and Gas Industry Used in pipelines that demand high reliability and safety standards. 4. Manufacturing They facilitate connections in machinery and process equipment.

Importance of Compliance

Adhering to DIN 3760 Type A standards is fundamental for manufacturers and engineers. Compliance ensures

- Safety Properly designed and manufactured flanges reduce the risk of leaks, which can lead to hazardous situations. - Interoperability Using standardized components allows for easier installation and maintenance, as well as compatibility with other systems. - Quality Assurance Following established standards helps maintain product quality, ensuring that all components meet rigorous performance criteria.

Conclusion

In conclusion, DIN 3760 Type A flanges play a vital role in the integrity and efficiency of pipeline systems across various industries. Understanding their specifications, applications, and importance highlights the significance of standardization in engineering. As industries continue to evolve, adhering to standards like DIN 3760 not only guarantees safety and reliability but also fosters innovation and efficiency. Whether in chemical processing, oil and gas, or water treatment, DIN 3760 Type A flanges remain an indispensable element of modern infrastructure. By prioritizing these standards, organizations can ensure their operations run smoothly and safely, ultimately contributing to the overall success of their projects.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories