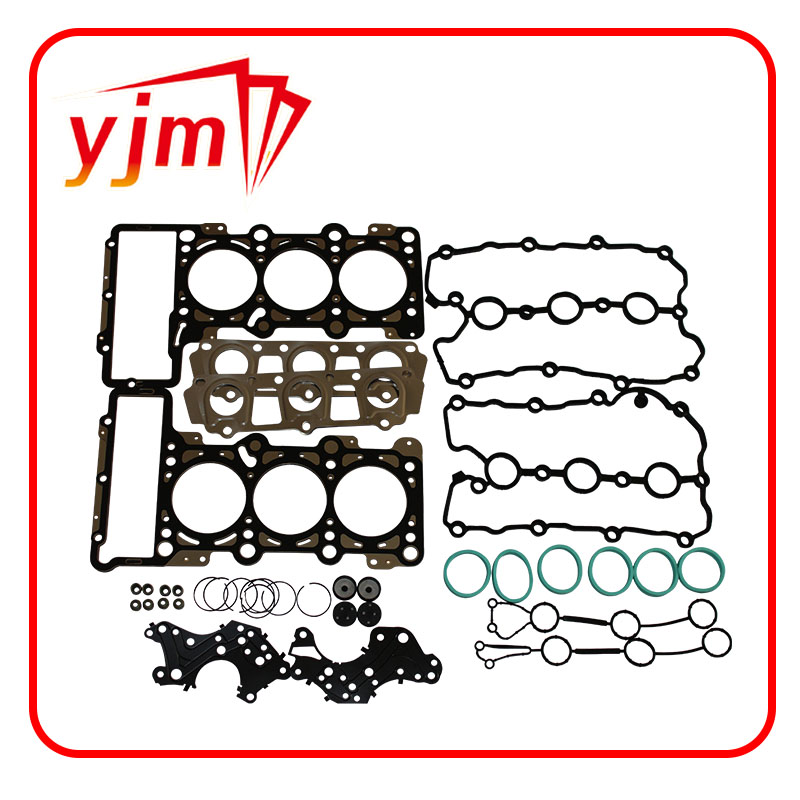

YJM Oil sump gasket 11 13 7 511 224

Trustworthiness in axial face seals is primarily built through rigorous testing and the reputation of the manufacturers. Reliable seals undergo a series of stress tests to mimic real-world conditions and are subject to quality assurance protocols that certify their suitability for industrial application. Additionally, customer reviews and industry certifications provide a reliable measure of a product's trustworthiness. Manufacturers who offer comprehensive warranties and after-sales support further reinforce consumer confidence in their products. For professionals looking to select the best axial face seals, it is crucial to consider the operational environment and the specific requirements of the machinery involved. Consulting with experts who have extensive industry experience can provide valuable insights into the selection process. Understanding the intricacies of seal technology and keeping abreast of the latest developments ensures that one stays ahead in industry knowledge. In conclusion, axial face seals are vital components that necessitate careful consideration in selection and application. Their role in safeguarding machinery from leaks cannot be understated, and their effectiveness relies heavily on the quality of design, material choice, and proper installation. By appreciating the expertise, authority, and trust that form the backbone of reliable axial face seals, industries can maintain operational efficiency and enhance the lifespan of their equipment. As the industry continues to evolve with technological advancements, staying informed and choosing reputable manufacturers will remain key to leveraging the full potential of axial face seals.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories