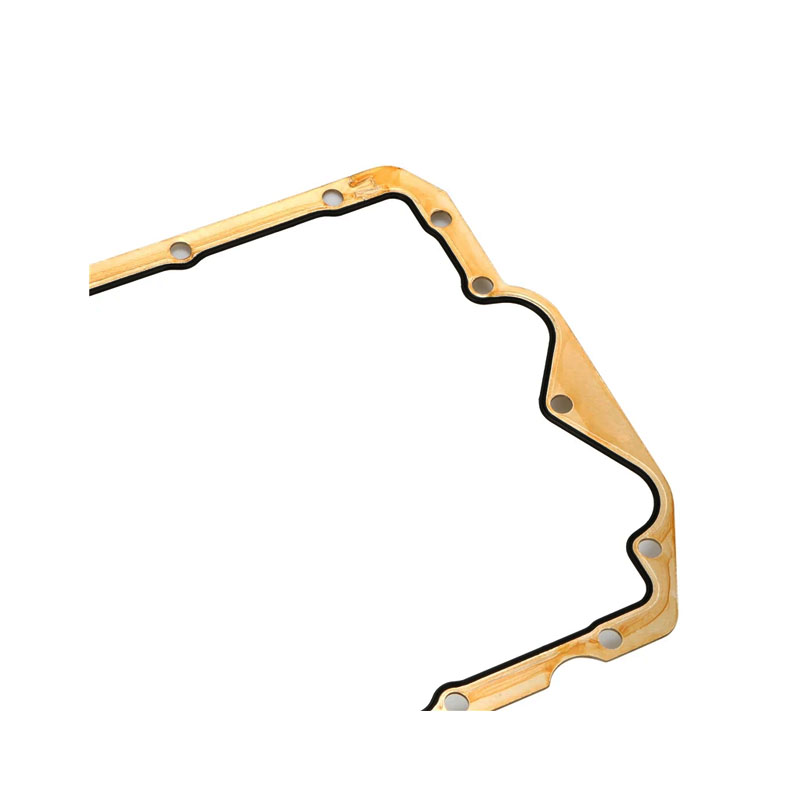

rear axle wheel seal

Understanding Rear Axle Wheel Seals Importance, Types, and Maintenance

When it comes to the smooth operation of any vehicle, few components are as vital yet overlooked as the rear axle wheel seal. Located at the rear of the axle, these seals play a crucial role in maintaining the integrity of the axle assembly, ensuring that fluids do not leak out and contaminants do not enter. This article aims to shed light on the importance of rear axle wheel seals, the different types available, and the maintenance practices necessary for optimal performance.

Importance of Rear Axle Wheel Seals

The primary function of a rear axle wheel seal is to prevent differential oil from leaking out of the axle assembly. This is critical not only for the protection of the axle's internal components but also for maintaining the vehicle's overall performance. If oil leaks occur, it can lead to inadequate lubrication, resulting in increased friction and wear on the gears and bearings. Ultimately, this can cause significant damage, requiring extensive and costly repairs.

Furthermore, these seals also prevent dirt, water, and other contaminants from entering the axle assembly. Contaminants can lead to corrosion, decreased efficiency, and premature failure of the axle components. Thus, a properly functioning rear axle wheel seal is vital for extending the lifespan of the vehicle and ensuring safety on the road.

Types of Rear Axle Wheel Seals

There are generally two main types of rear axle wheel seals conventional rubber-sealed designs and modern silicone-based seals.

1. Conventional Rubber-Sealed Designs These are the most common types found in older vehicles and many mid-range modern cars. They are made from durable rubber compounds that can withstand a wide range of temperatures and pressures. However, over time, rubber can degrade, leading to potential leaks.

2. Silicone-Based Seals More modern vehicles often utilize silicone-based seals, which offer enhanced resistance to extreme temperatures and aging. These seals are designed to maintain their integrity much longer than rubber seals. Their flexibility makes them better suited for vehicles that are regularly exposed to harsher driving conditions.

rear axle wheel seal

In addition to the materials used, the design of the seal can also vary. For instance, some seals might feature double-lipped designs that provide enhanced protection against leaks.

Maintenance Tips

Proper maintenance of rear axle wheel seals can prevent costly repairs and ensure the longevity of your vehicle. Here are some essential maintenance tips

1. Regular Inspections Regularly inspect the seals for signs of wear, such as cracks or deformation. Early detection of these signs can prevent more severe leaks and damage.

2. Fluid Checks Keep an eye on differential fluid levels. Low fluid can indicate a leak caused by a faulty seal. If you find yourself needing to add fluid frequently, it’s wise to have the seals inspected.

3. Environmental Considerations If you often drive in muddy or wet conditions, consider using high-quality seals designed for such environments. These seals can offer additional protection against contaminants.

4. Professional Maintenance Ensure that any changes to your vehicle’s rear axle components are handled by a professional. Proper installation of new seals is critical for their performance and longevity.

Conclusion

In conclusion, the rear axle wheel seal is an often-overlooked component that plays a significant role in the overall functioning of a vehicle. Understanding its importance, the different types available, and how to maintain it can save vehicle owners from costly repairs and enhance safety on the road. By paying attention to this small yet critical piece of engineering, you can ensure that your vehicle operates at its best for years to come.

-

Understanding Polaris Front Differentials: Key Components for Off-Road Performance

News Jun.20,2025

-

Understanding Crankshaft Seals and Gaskets: Essential Components for Engine Longevity

News Jun.20,2025

-

Understanding Crankshaft Oil Seals: Vital Protection for Engine Performance

News Jun.20,2025

-

The Vital Role of Front and Rear Crankshaft Seals in Engine Protection

News Jun.20,2025

-

Rear Crankshaft Seals: Protecting Your Engine from the Back End

News Jun.20,2025

-

Crank Oil Seals: What They Do, How They Fail, and What They Cost

News Jun.20,2025

-

Understanding Oil Crush Washers: A Small Component with a Big Role in Vehicle Maintenance

News Jun.19,2025

Products categories