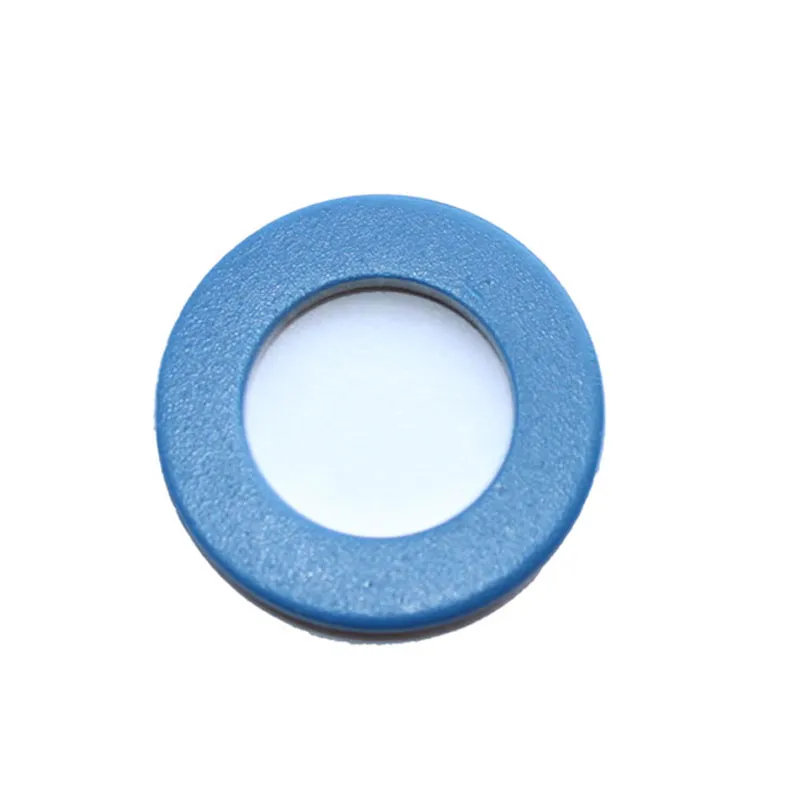

Durable O-Rings Designed for Resistance to Petrol and Other Hydrocarbon Fluids

Understanding Petrol Resistant O-Rings Importance, Applications, and Selection

In many industries, particularly in automotive, aerospace, and industrial machinery, the reliability of components is paramount to ensure smooth and safe operations. One such critical component is the O-ring, specifically those designed to be petrol resistant. O-rings are circular seals that provide a barrier between two or more components to prevent the leakage of fluids and gases. When dealing with fuels, especially petrol, the choice of materials for these O-rings becomes crucial due to the aggressive nature of petroleum products.

What Makes O-Rings Petrol Resistant?

Petrol-resistant O-rings are typically made from materials that can withstand the destructive effects of petroleum-based fuels. Common materials include Fluoroelastomer (Viton), Nitrile Rubber (Buna-N), and Ethylene Propylene Diene Monomer (EPDM). Each of these materials offers unique advantages

1. Fluoroelastomer (Viton) Known for its exceptional resistance to high temperatures and aggressive chemicals, Viton is a top choice for applications involving petrol. It maintains its elasticity and performance under extreme conditions, ensuring a long-lasting seal.

2. Nitrile Rubber (Buna-N) This is one of the most commonly used materials for O-rings, particularly in oil and fuel applications. It has good fuel resistance and handles various temperatures well, making it a cost-effective option for many industries.

3. EPDM While not as widely used for petrol applications due to its susceptibility to oil swelling, EPDM can still provide a reasonable level of resistance in diluted petrol situations, especially when combined with suitable additives.

Applications of Petrol Resistant O-Rings

The applications of petrol-resistant O-rings span various industries, from automotives to aviation. Here are a few examples

- Automotive Fuel Systems In vehicles, petrol-resistant O-rings are essential for fuel injectors, fuel filters, and pumps

. The integrity of these seals ensures that petrol does not leak, which could lead to dangerous situations, including fires.petrol resistant o rings

- Aerospace In aircraft, fuel systems are under extreme conditions, both in pressure and temperature. O-rings which can resist petrol and jet fuels are vital for ensuring safety and reliability during flight operations.

- Industrial Machinery Equipment that operates with various types of fuels, including petrol, often relies on O-rings to maintain proper operation. Any failure in these seals could result in significant downtime and maintenance costs.

Selecting the Right Petrol Resistant O-Ring

When selecting the appropriate petrol-resistant O-ring, several factors must be considered

1. Material Compatibility The chosen material should not only resist petrol but also be compatible with other fluids that may be present in the system.

2. Temperature Range Understanding the temperature range in which the O-ring will operate is crucial. Certain materials will degrade more quickly when exposed to high temperatures.

3. Pressure Conditions High-pressure environments require O-rings that can maintain their integrity without deformation. The selected O-ring should be rated for the pressures expected in the application.

4. Aging Resistance Over time, exposure to petrol and other environmental factors can degrade materials. Selecting O-rings that offer good aging resistance will enhance the longevity of the seals.

5. Size and Specifications The correct size is critical for ensuring a proper seal. O-rings come in various sizes, and adhering to specifications is essential for effective performance.

In conclusion, petrol-resistant O-rings play a vital role in various industries where fuel systems are involved. Their selection should be based on material properties, application requirements, and environmental conditions to ensure reliable and efficient operations. Understanding the significance of these components not only enhances safety but also optimizes equipment performance, reducing downtime and maintenance costs. As industries continue to evolve with new technologies and materials, the advancements in O-ring production will play a crucial role in the future of fuel handling and management.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories