Understanding Hub Oil Seals and Their Importance in Vehicle Maintenance

Understanding Hub Oil Seals Functionality and Importance

In the realm of mechanical engineering and automotive technology, the hub oil seal is a vital component that plays a crucial role in ensuring the smooth functioning of various machinery and vehicles. Often overlooked, these seals serve a significant purpose in maintaining the performance and lifespan of mechanical systems, particularly in wheel hubs and differentials.

What is a Hub Oil Seal?

A hub oil seal is a specially designed sealing device that is typically installed around the hub of a wheel or inside a gear housing. Its primary function is to prevent the leakage of lubricating oil while simultaneously keeping contaminants such as dirt, moisture, and debris from entering the lubrication system. Made from a variety of materials, including rubber and synthetic compounds, hub oil seals are engineered to withstand a wide range of temperatures and pressures.

How Hub Oil Seals Function

The design of a hub oil seal includes several important features that enable it to perform its role effectively

. The seal consists of a flexible lip that presses against the shaft or hub surface, creating a barrier to oil leakage. This dynamic sealing mechanism allows for a precise fit that adapts to the movements of the rotating parts, ensuring that oil remains contained while still accommodating necessary motion.Furthermore, oil seals often incorporate a metal casing that adds structural integrity and helps to maintain the seal's shape under operating conditions. The combination of the flexible lip and sturdy casing is crucial for providing a sustainable interface that can resist wear and tear over time.

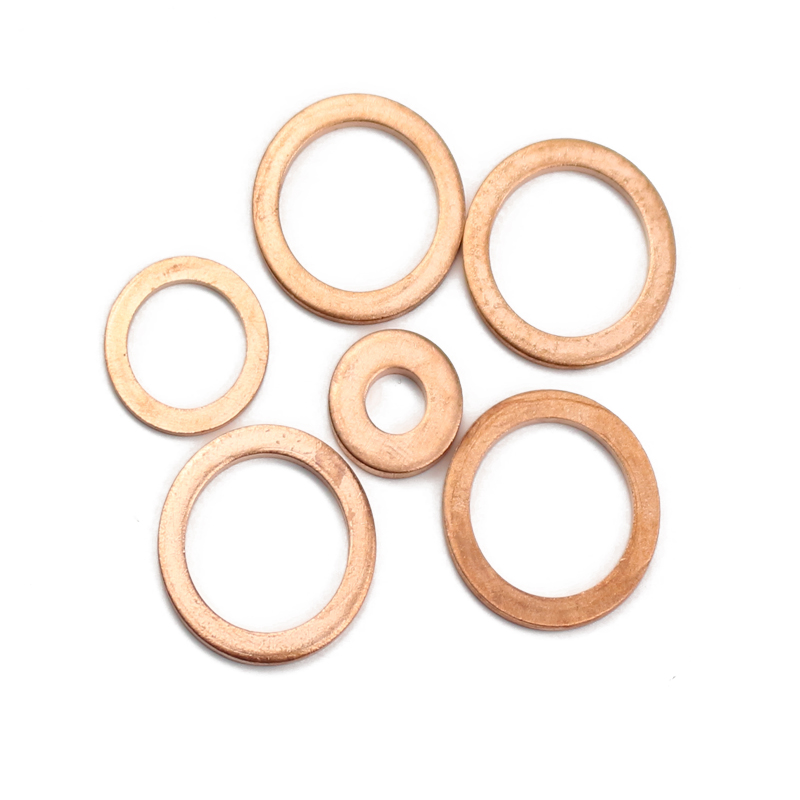

hub oil seal

Importance of Hub Oil Seals

1. Preventing Lubrication Loss One of the most critical functions of hub oil seals is to prevent the loss of lubricants from machinery. Oil lubricates moving parts, reducing friction and wear, which is essential for the longevity of components. Without effective seals, lubricants could leak out, leading to insufficient lubrication, increased friction, and ultimately mechanical failure.

2. Contaminant Protection Hub oil seals act as barriers that protect the lubrication system from harmful contaminants. Dust, dirt, and moisture can compromise the integrity of lubricants, leading to corrosion and damage to critical parts. By preventing these contaminants from entering, oil seals contribute significantly to the reliability and efficiency of machinery.

3. Noise Reduction An often overlooked benefit of functioning hub oil seals is their role in minimizing noise produced by the movement of mechanical parts. By maintaining proper lubrication and sealing against contaminants, these seals help ensure that machinery operates quietly. This is particularly important in automotive applications, where excessive noise can affect user experience.

4. Cost-Effectiveness Although they are relatively small components, the failure of hub oil seals can lead to extensive damage and expensive repairs. Regular maintenance and timely replacement of worn seals can prevent costly breakdowns and extend the life of vehicles and equipment, making them a cost-effective investment in the long run.

Conclusion

In summary, hub oil seals may be small in size, but their role in the functionality and longevity of machinery is paramount. By preventing the loss of lubricants and protecting against contaminants, these seals ensure optimal performance and reliability. As industries continue to evolve, the importance of maintaining and understanding these seemingly minor components will only grow, highlighting the significance of proper maintenance practices in both automotive and mechanical applications. Whether you're a technician, an engineer, or simply an automotive enthusiast, recognizing the value of hub oil seals is crucial for the effective management of machinery.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories