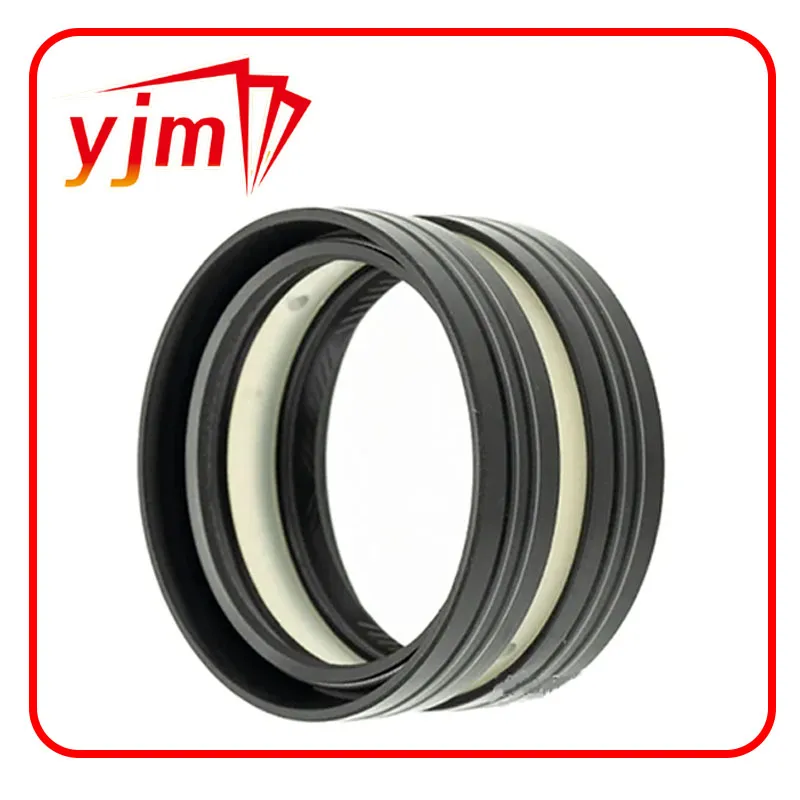

engine oil pan gasket

Speaking from expertise, understanding the intricate balance between material properties and functional requirements is foundational in gasket selection. The interaction of gaskets with various lubricants and exposure to varying thermal and pressure conditions over time necessitates a rigorous assessment. Expertise lies in not only understanding the immediate implications of gasket failure but also forecasting long-term durability based on historical data and material science developments. Experts suggest regular inspection and performance testing, assuring engineers and plant managers of their equipment's safety and efficiency. The authoritativeness of a particular oil gasket often hinges upon the reputation of its manufacturer. Established manufacturers are usually more invested in research and development, continuously innovating to meet industry demands. They are more likely to adhere to international manufacturing standards and quality control protocols, providing a seal that is both reliable and long-lasting. Engaging with manufacturers that have earned certifications, such as ISO 9001, further adds a layer of credibility and assurance to the products they offer. These certifications indicate a commitment to quality consistency and safety, vital factors in the high-stakes environments where oil gaskets are often deployed. Trustworthiness in the context of oil gaskets is built through empirical validation, customer reviews, and a history of consistent performance. Trusted suppliers are transparent about the specifications and limitations of their gaskets. They offer extensive customer support, including technical assistance, to help resolve installation or performance issues promptly. Additionally, providing warranties and responsive post-purchase service fosters customer confidence in the reliability of their products. In conclusion, understanding the comprehensive functionality and application of oil gaskets is essential for optimizing machinery performance and preventing leaks. The combined forces of experience, expertise, authoritativeness, and trustworthiness shape the selection of the right oil gasket. By leveraging these factors, industries can ensure operational longevity and efficiency, thus safeguarding their investments and promoting safety. As new materials and technologies emerge, staying informed through expert insights and trusted sources remains pivotal for anyone tasked with maintaining or procuring mechanical systems requiring robust seals.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories