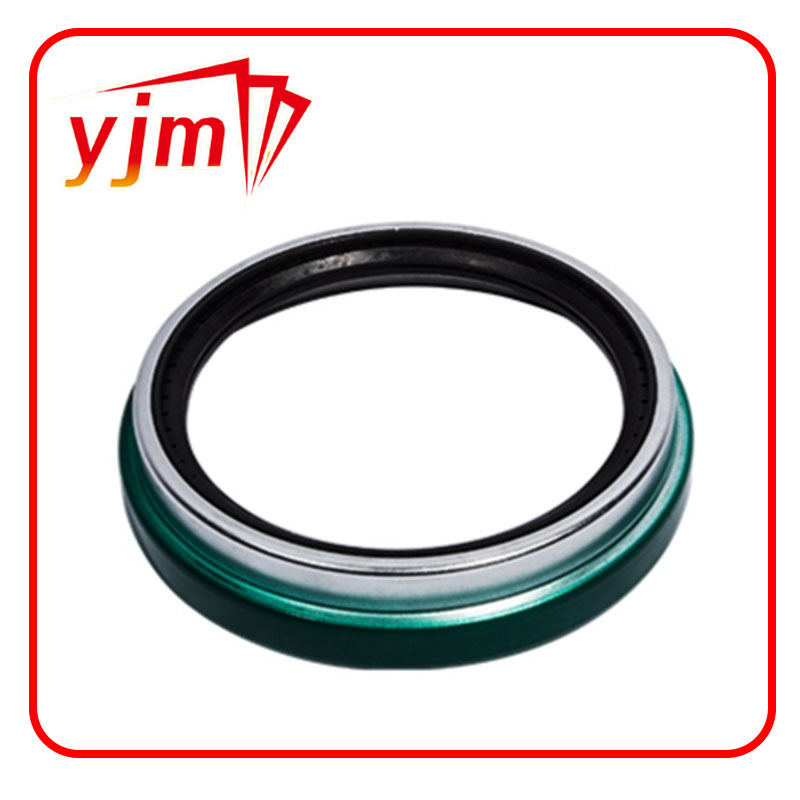

gear box seals

Understanding Gearbox Seals Importance and Functionality

Gearbox seals play a crucial role in the performance and longevity of any vehicle or machinery that relies on a gearbox for transmission. These seals are designed to prevent the leakage of lubricants and protect the internal components of the gearbox from external contaminants like dirt, dust, and moisture. The significance of gearbox seals cannot be overstated, as they contribute to the efficient functioning of various mechanical systems.

Understanding Gearbox Seals Importance and Functionality

Gearbox seals come in various types, each suitable for different applications. The most common types include lip seals, O-rings, and specialty seals designed for specific conditions. Lip seals, for instance, are engineered to provide a tight seal around rotating shafts, preventing lubricant leakage while maintaining minimal friction. O-rings, on the other hand, are circular seals that create a barrier between two surfaces, preventing the ingress of harmful contaminants. Understanding the specific requirements of a gearbox is essential in selecting the appropriate type of seal.

gear box seals

Materials used in the manufacture of gearbox seals are also a significant consideration. Common materials include rubber compounds, polyurethanes, and thermoplastics. Each material offers different advantages in terms of resistance to chemicals, temperature variations, and wear. For example, high-temperature environments may require seals made from specialized materials that can withstand extreme conditions without degrading.

The proper installation and maintenance of gearbox seals are vital for ensuring their functionality. Improper installation can lead to leaks, resulting in loss of lubricant and potentially catastrophic damage to gearbox components. Regular inspections are also recommended to check for signs of wear, deformation, or damage. Early detection of issues can save significant repair costs and prevent extensive downtime.

Moreover, advancements in technology have led to the development of innovative seal designs, including self-lubricating seals and those that feature integrated wear sensors. These modern seals improve reliability and provide valuable data on the operational condition of the gearbox, aiding in predictive maintenance practices.

In conclusion, gearbox seals are essential components that significantly impact the efficiency and durability of gearboxes across various applications. Their role in containing lubricants and protecting against contaminants is vital for optimal performance. As technology evolves, so too will the designs and materials used in gearbox seals, further enhancing their effectiveness and reliability. Understanding the importance of these seals helps in making informed decisions regarding maintenance and replacements, ultimately leading to improved machinery performance and reduced operational costs.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories