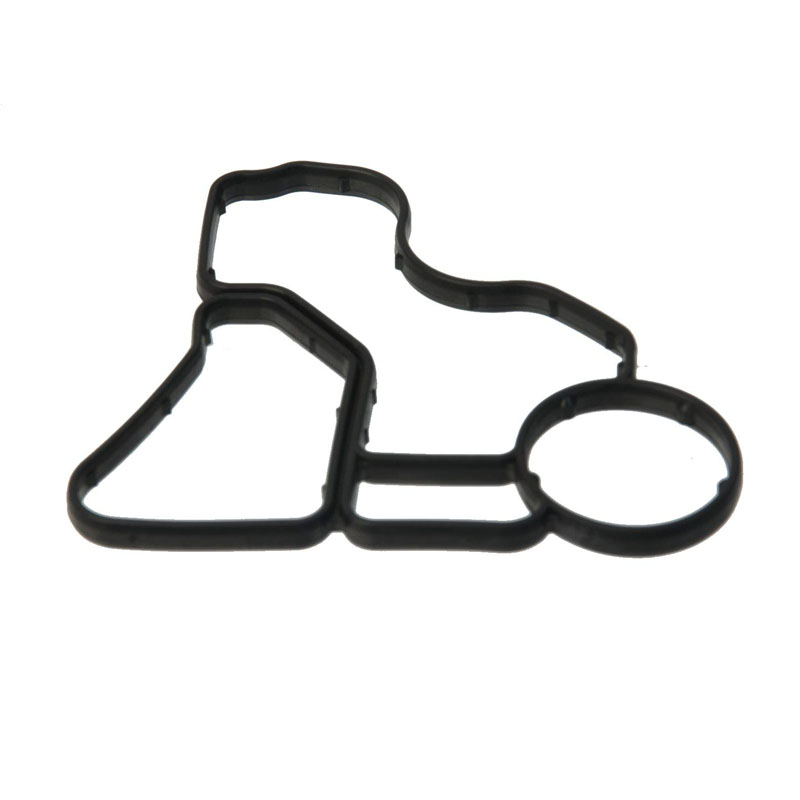

o ring gasket

The Importance of O-Ring Gaskets in Industrial Applications

O-ring gaskets are an essential component in various industrial applications, serving as effective sealing elements that prevent fluid and gas leakage. These simple yet highly functional rings are predominantly made from elastomers, which provide elasticity and resistance to different environmental factors. When used correctly, O-ring gaskets can enhance the performance and longevity of machinery, equipment, and piping systems, making them indispensable in many industries, including automotive, aerospace, oil and gas, and manufacturing.

Understanding O-Rings

An O-ring is a circular sealing element with a round cross-section. Its design allows it to compress when inserted into a groove between two components, forming a reliable barrier against the escape of gases or liquids. The simplicity of the O-ring design is one of its greatest advantages; it can be easily manufactured in various sizes and materials to suit specific applications. Common materials used for O-rings include rubber compounds such as nitrile (Buna-N), fluorocarbon (Viton), silicone, and EPDM, each providing different properties such as chemical resistance, temperature tolerance, and flexibility.

Applications in Different Industries

1. Automotive In the automotive industry, O-ring gaskets are commonly found in engines, transmissions, and fuel systems. They help ensure a tight seal to prevent oil and coolant leaks, which can lead to costly repairs and safety hazards. The durability and temperature resistance of O-rings make them ideal for high-performance automotive applications.

2. Aerospace The aerospace industry demands high-performance sealing solutions due to the extreme conditions faced by aircraft components. O-ring gaskets are used in hydraulic systems, fuel tanks, and pressurized cabins, where reliability and safety are paramount. The materials used for aerospace O-rings must comply with strict regulatory standards to ensure they can withstand significant variations in pressure and temperature.

3. Oil and Gas In the oil and gas sector, O-rings play a crucial role in preventing leaks in drilling equipment, pipelines, and valves. The harsh environments often experienced in this industry require O-rings made from specialized materials capable of resisting corrosive substances and extreme temperatures. The ability to maintain a secure seal under high pressure is vital for operational safety and efficiency.

4. Manufacturing O-ring gaskets are widely used in various manufacturing processes, including food processing, pharmaceuticals, and chemical production. In these applications, O-rings help maintain hygiene and safety by preventing contamination from leaks. The ability to select O-rings made from food-safe materials is essential in ensuring compliance with health regulations.

o ring gasket

Selection of O-Ring Gaskets

Choosing the right O-ring for a specific application involves considering several factors

- Material Compatibility It is crucial to select an O-ring material that is compatible with the substances it will encounter. For instance, certain chemicals can degrade rubber compounds, making it essential to choose materials with the right chemical resistance.

- Temperature Range O-rings must be able to withstand the temperature extremes of their working environment. Each material has its own range of operational temperatures, and selecting the right one can prevent premature failure.

- Pressure Requirements The application’s pressure conditions should dictate the O-ring’s design and material. High-pressure applications may require O-rings with specific cross-sections or materials to ensure they do not deform or extrude from the sealing groove.

- Dynamic vs. Static Applications O-rings can be used in both static and dynamic sealing applications. Dynamic applications involve moving parts, such as shafts or pistons, while static applications are in fixed positions. The selection process will vary based on these conditions.

Conclusion

O-ring gaskets may seem like a small component, but their role in ensuring operational efficiency and safety across various industries is enormous. With a wealth of materials and designs available, selecting the right O-ring is critical to preventing leaks and ensuring the seamless operation of equipment and machinery. Investing in high-quality O-ring gaskets not only enhances performance but also extends the lifespan of components, ultimately leading to reduced maintenance costs and higher productivity. As industries continue to evolve, the importance of reliable sealing solutions like O-rings will only become more significant.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories