Understanding the Importance of Drain Crush Washers in Plumbing Applications

Understanding Drain Crush Washers Importance and Applications

Maintaining the efficiency of various mechanical systems often hinges on the small components that are easily overlooked. One such component is the drain crush washer, a critical part in ensuring leak-proof seals in plumbing and mechanical applications. This article delves into the significance, functions, and applications of drain crush washers, highlighting their importance in both residential and industrial settings.

What is a Drain Crush Washer?

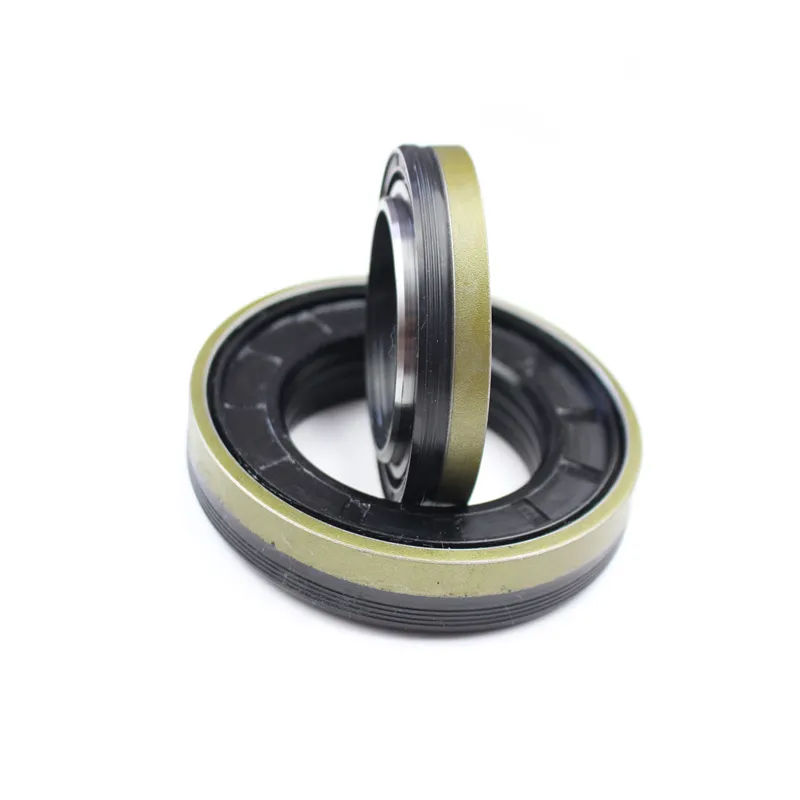

A drain crush washer is a thin, flat washer made from materials such as rubber, silicone, or metal. It is specifically designed to be compressed between two surfaces, creating a tight seal that prevents fluid leakage. The primary function of a crush washer is to eliminate gaps between mating parts, ensuring that fluids such as oil, water, and other liquids do not escape. These washers are commonly used in plumbing fixtures, automotive applications, and various industrial machines.

The Mechanism of a Crush Washer

The effectiveness of a crush washer lies in its ability to deform upon installation. When tightened between two surfaces, the washer compresses, which helps it conform to any irregularities on the surfaces it connects. This deformation creates a solid seal that effectively prevents leaks. Unlike standard flat washers, which do not compress in the same way, crush washers are specifically engineered to ensure a snug fit even in the most challenging conditions.

Benefits of Using Drain Crush Washers

1. Leak Prevention The primary advantage of drain crush washers is their ability to prevent leaks. This is crucial in preventing waste fluids from escaping, which can lead to environmental issues, safety hazards, and costly damages.

2. Durability Made from robust materials, crush washers can withstand various pressures and temperatures, making them ideal for both high-stress and high-temperature applications.

drain crush washer

3. Versatility Drain crush washers are used in a variety of applications. From automotive oil pans to plumbing systems, their adaptability makes them indispensable in numerous industries.

4. Cost-Effectiveness While they may seem like a minor component, using high-quality crush washers can reduce the likelihood of severe leaks, thereby avoiding costly repairs and ensuring the longevity of machinery and plumbing systems.

Applications of Drain Crush Washers

Drain crush washers find applications in numerous settings, such as

- Automotive In vehicles, crush washers are often used in drain plugs for engines and differentials to prevent oil leaks. Their reliability is vital for maintaining proper fluid levels and ensuring engine health.

- Plumbing In residential and commercial plumbing, these washers are employed in sink drains, shower drains, and other fixtures. Their capacity to create a reliable seal is critical in preventing water damage.

- Industrial Machinery In heavy machinery and industrial applications, crush washers are utilized to secure hydraulic lines and other connections that require a leak-proof seal under pressure.

Conclusion

In summary, drain crush washers may be small, but their role in various systems is undeniably significant. By providing a reliable, leak-proof seal, they help maintain the efficiency and safety of plumbing and mechanical systems across multiple industries. When selecting crush washers for your specific application, it is essential to consider the material and size that best fits the requirements, ensuring optimal performance and durability. Investing in quality drain crush washers is a step towards effective leak prevention and long-term reliability in your plumbing and machinery maintenance practices.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories