China's Oil Seal Manufacturing Industry Overview and Insights

Oil Seal Production in China An Overview

Oil seals, commonly used in various industries, play a crucial role in ensuring the efficiency and longevity of machinery by preventing fluid leakage and retaining lubrication. As global demand for these components continues to rise, China has emerged as a leading manufacturer in this sector, thanks to its vast industrial capabilities and advancements in technology.

Oil Seal Production in China An Overview

One of the primary advantages of sourcing oil seals from China is cost-effectiveness. The combination of lower labor costs and economies of scale allows manufacturers to offer competitive pricing without compromising on quality. Moreover, many Chinese companies have invested heavily in research and development, resulting in improved product designs and materials that enhance the performance of oil seals. This investment has enabled Chinese manufacturers to produce oil seals that can withstand extreme temperatures, high pressures, and aggressive chemicals.

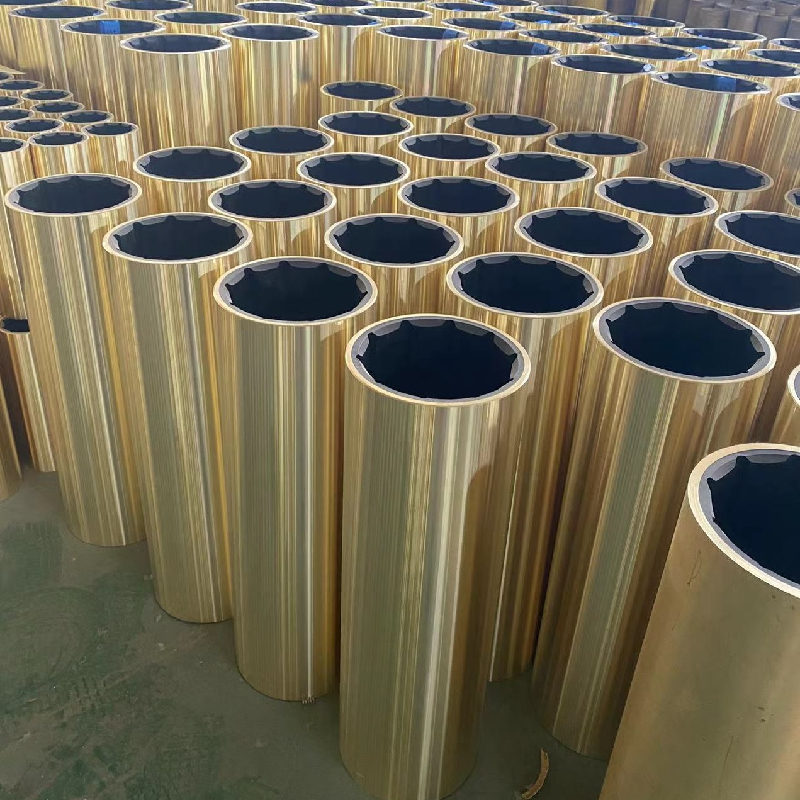

oil seal china

Furthermore, China has established itself as a hub for innovation in manufacturing processes. The integration of automated technologies and advanced materials has revolutionized the production of oil seals, leading to higher precision and durability. For instance, advancements in polymer science have paved the way for the development of high-performance elastomers that significantly improve the seals' resilience and lifespan. This technological progress not only elevates the quality of the products but also boosts the overall competitiveness of Chinese manufacturers in international markets.

The export of oil seals from China has seen a substantial increase, with key markets including North America, Europe, and Asia. Chinese manufacturers are not only meeting domestic needs but are also catering to international clients, contributing to the globalization of the supply chain. The establishment of reliable logistics and shipping networks further facilitates this growing trend, ensuring timely deliveries and reducing costs for international buyers.

However, the oil seal industry in China is not without its challenges. Increasing environmental regulations and the push for sustainability necessitate a shift towards greener production methods. Many manufacturers are now focusing on eco-friendly materials and processes to reduce their carbon footprint and comply with international standards. This transition is crucial as global customers increasingly prioritize sustainability in their procurement processes.

In conclusion, the oil seal industry in China stands out due to its cost-effectiveness, innovative manufacturing practices, and robust supply chain capabilities. As technology advances and environmental concerns come to the forefront, Chinese manufacturers are poised to adapt and lead the way in producing high-quality, sustainable oil seals. This evolution not only benefits the industry but also contributes positively to the global market, ensuring that machinery operates efficiently and reliably for years to come.

-

Understanding Oil Drain Plugs: Types, Issues, and Replacements

News Jun.26,2025

-

Understanding Nylon Drain Plug Washers: A Flexible Solution for Leak-Free Oil Changes

News Jun.26,2025

-

The Importance of the Drain Plug Washer: Everything You Need to Know About Crush Washers

News Jun.26,2025

-

The Essential Guide to Oil Drain Plug Washers: Types, Uses, and Replacements

News Jun.26,2025

-

How to Identify and Fix Common Engine Oil Leaks

News Jun.26,2025

-

Choosing the Right Crush Washer: A Guide to M14 and M18 Aluminum Drain Plug Washers

News Jun.26,2025

-

Why Crush Washers Matter: The Small Seal That Keeps Oil In and Problems Out

News Jun.25,2025

Products categories