Understanding Ship Propeller Shaft Bearings and Their Importance in Marine Engineering

Understanding Ship Propeller Shaft Bearings Key Components for Marine Propulsion

In the intricate world of marine engineering, the propulsion system of a ship is one of its most vital components. At the heart of this system lies the propeller shaft bearing, a crucial part that facilitates smooth operation and ensures the longevity of marine vessels. This article explores the importance, functionality, types, and maintenance of ship propeller shaft bearings.

What are Propeller Shaft Bearings?

Propeller shaft bearings are mechanical components that support the rotating shaft which transmits power from the engine to the propeller. These bearings are designed to withstand heavy loads and harsh marine conditions, enabling the efficient conversion of mechanical energy into thrust. Positioned within the hull of the ship, they play a significant role in facilitating the ship's movement through water.

Importance of Propeller Shaft Bearings

The primary function of propeller shaft bearings is to reduce friction between the rotating shaft and the surrounding structures. This is essential for several reasons

1. Load Distribution Bearings help in evenly distributing the loads encountered during operation, which prevents undue stress on any single part of the shaft or hull.

2. Vibration Damping Propeller shafts experience significant vibrations due to the dynamic forces acting upon them. Bearings mitigate these vibrations, contributing to smoother operation and reducing wear on other components.

3. Alignment Maintenance Properly installed bearings help to maintain the alignment of the shaft, ensuring efficient power transmission from the engine to the propeller.

4. Sealing and Protection Many bearings come with built-in seals that keep out seawater and debris, thus protecting the internal components from corrosion and wear.

Types of Propeller Shaft Bearings

There are several types of ship propeller shaft bearings, each suited for different applications and operational conditions

1. Bronze Bearings Known for their excellent wear resistance, bronze bearings are commonly used in marine environments. They provide good load-bearing capabilities and take well to lubrication.

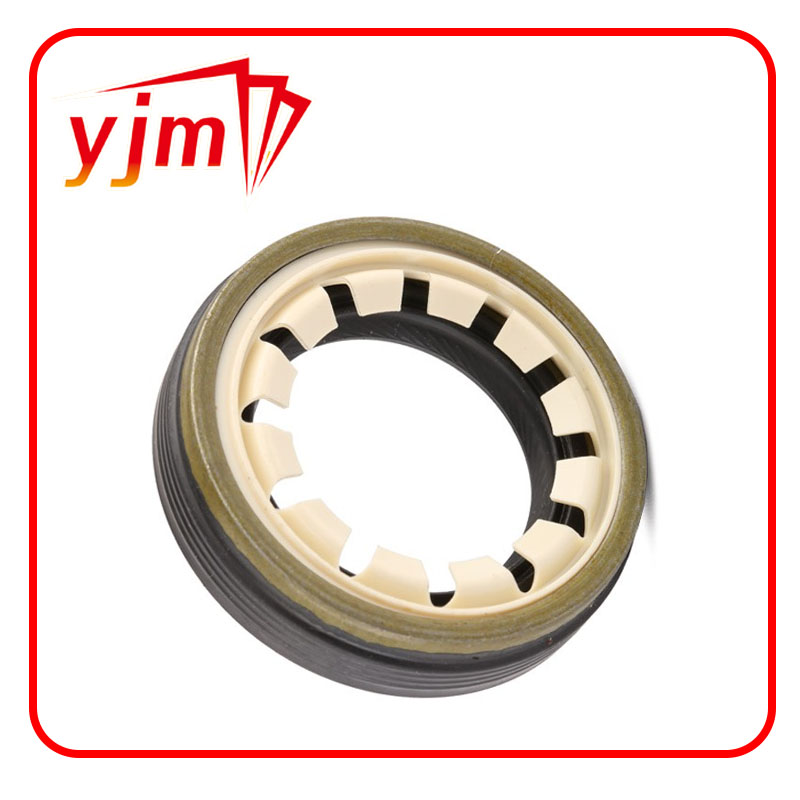

ship propeller shaft bearing

2. Composite Bearings Made from a combination of materials, these bearings offer lightweight characteristics and high corrosion resistance, making them ideal for modern vessels.

3. Roller Bearings These bearings use rolling elements to reduce friction and are typically employed in high-load applications where durability is essential.

4. Sliding Bearings Simple in design, sliding bearings can be made from various materials and offer good performance in applications where space constraints exist.

Maintenance of Propeller Shaft Bearings

To ensure the longevity and efficiency of propeller shaft bearings, regular maintenance is crucial. Here are some best practices

1. Regular Inspections Periodic checks for wear, corrosion, and alignment are essential. Operators should inspect the condition of the bearings, looking for signs of pitting or abnormal wear.

2. Lubrication Bearing lubrication is critical for reducing friction and preventing overheating. The type of lubricant used should be suitable for marine conditions and the specific type of bearing in place.

3. Monitoring Temperature Excessive heat can indicate a problem with the bearings or the lubrication system. Utilizing temperature sensors can help in early identification of potential failures.

4. Sealing Integrity Ensuring that seals are intact is vital for protecting against seawater intrusion. Damaged seals should be replaced promptly to maintain bearing integrity.

5. Record Keeping Keeping detailed logs of inspections, maintenance actions, and any operational irregularities can help in diagnosing potential issues before they become critical.

Conclusion

Ship propeller shaft bearings are essential for the efficient functioning of marine propulsion systems. Understanding their importance, types, and maintenance requirements is crucial for marine engineers and vessel operators. By ensuring proper care, these components can continue to perform effectively, providing the reliability needed for safe and economical ship operations. As the maritime industry evolves, attention to these critical components will remain paramount in the relentless pursuit of innovation and efficiency in marine engineering.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories