Sump Plug Seal Replacement and Maintenance Guide for Optimal Performance

Understanding Sump Plug Seals Importance, Types, and Maintenance

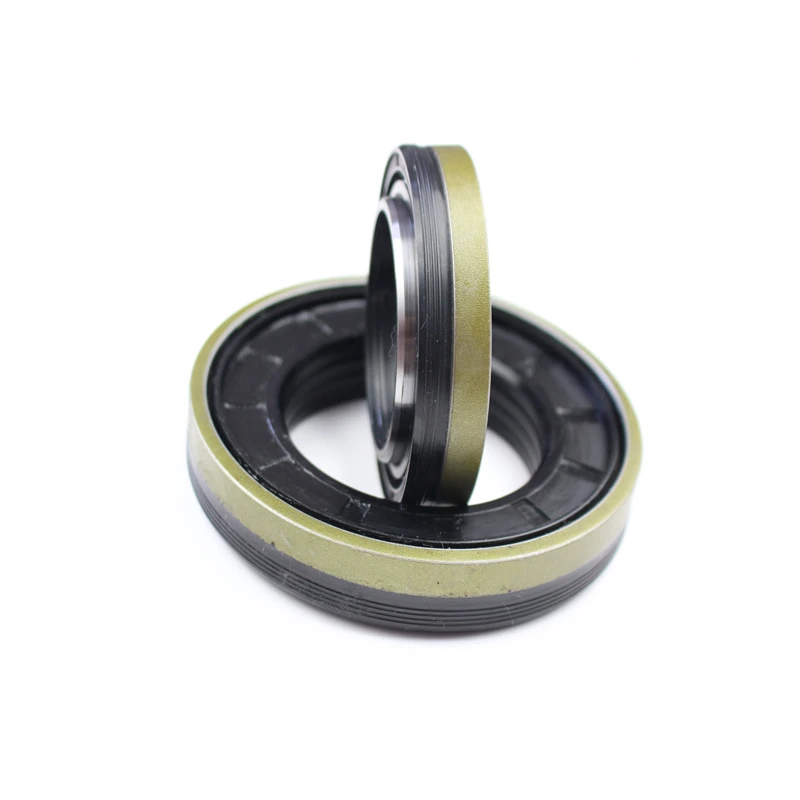

A sump plug seal, often referred to as an oil plug washer, plays an essential role in ensuring the effective operation of various machinery, particularly in automotive and marine applications. This small yet critical component helps maintain fluid integrity within oil sumps, preventing leaks and ensuring optimal performance.

The Importance of Sump Plug Seals

Sump plug seals are designed to create a tight and secure seal around the oil drain plug, which is critical for preventing oil leakage. Oil leaks can lead to significant problems, including reduced lubrication of engine components, contamination of the environment, and, ultimately, serious engine damage. With proper sealing, sump plug seals contribute to the overall health of the machine by ensuring that oil remains in the system, safeguarding components from wear and tear.

Moreover, effective sump plug seals help maintain the correct oil levels in engines or gearboxes. Low oil levels can result in inadequate lubrication, which can cause increased friction and overheating. Thus, utilizing high-quality sump plug seals is indispensable for machinery reliability and longevity.

Types of Sump Plug Seals

There are several types of sump plug seals available, each designed for specific applications and materials

. The most common types include1. Rubber Seals These are perhaps the most widely used sump plug seals. They are flexible and provide an excellent seal against various oils and fluids. Rubber seals work well across a range of temperatures, making them suitable for a variety of machinery.

2. Copper Washers Commonly used in automotive applications, copper washers offer high durability and excellent sealing properties at elevated temperatures. Due to their malleability, they can form tightly around the surface to create a leak-proof barrier.

3. Aluminum Washers Similar to copper, aluminum washers are lightweight and corrosion-resistant, making them a good choice for vehicles that experience high levels of moisture. They are often used in marine applications due to their resistance properties.

sump plug seal

4. Polymer Seals In recent years, advanced materials such as PTFE (Polytetrafluoroethylene) have been introduced as sump plug seals. These seals provide excellent chemical resistance and can withstand extreme temperatures, which is particularly beneficial in high-performance engines.

Maintenance Considerations

For optimal performance, sump plug seals require regular maintenance and inspection. Here are some best practices to consider

1. Regular Inspection Check the sump plug seal periodically for signs of wear or damage. Look for cracks, swelling, or tears in the seal material. Catching issues early can prevent more significant problems down the line.

2. Proper Replacement Sump plug seals are generally low-cost components that should be replaced whenever the oil is changed or when the plug is removed. Using a damaged or worn-out seal can lead to leaks, so it’s advisable to invest in a new seal every time.

3. Use the Right Seal Ensure that you are using the correct type of sump plug seal for your specific application. Consult the manufacturer’s guidelines for recommendations on materials and sizes.

4. Torque Specifications When reinstalling the sump plug, adhere to the manufacturer’s torque specifications. Over-tightening can damage the seal, while under-tightening may lead to leaks.

Conclusion

In conclusion, sump plug seals may seem like small components, but they are crucial for the efficient operation of machinery. Their importance in preventing leaks and ensuring proper lubrication cannot be overstated. By understanding the different types of seals available and adhering to regular maintenance practices, machine operators can enhance the longevity and performance of their equipment, ultimately leading to improved efficiency and reduced operational costs. Whether in automotive settings or marine applications, ensuring the integrity of your sump plug seal is a wise investment in machinery care.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories