Seal for Oil Hub Management and Efficiency Improvements

The Oil Hub Seal Ensuring Quality and Reliability in the Oil Industry

In the world of oil and gas, where efficiency and reliability are paramount, the significance of a well-designed sealing system cannot be overstated. Among the myriad components that contribute to operational success, the Oil Hub Seal stands out as a crucial element. This specialized sealing solution plays a vital role in maintaining the integrity of oil hubs, preventing leaks and ensuring the smooth operation of various equipment used in the industry.

Understanding the Oil Hub Seal

Oil hubs are integral to the transportation and storage of crude oil and refined products. They serve as connection points for pipelines, storage tanks, and distribution systems. The Oil Hub Seal is specifically designed to prevent the escape of oil and other fluids, while also protecting against contaminants that could compromise the quality of the transported product.

Constructed from high-performance materials, these seals are engineered to withstand extreme temperatures, pressures, and chemical exposures typical in the oil industry. They are commonly used in valves, pumps, and flanges within oil terminals and refineries, providing a reliable barrier against leaks.

Types of Oil Hub Seals

There are several types of Oil Hub Seals, each tailored for specific applications within the oil industry

1. O-Ring Seals These are circular seals that fit into a groove, providing a tight seal when compressed. O-rings are versatile and can be used in various applications, from pipelines to storage tanks.

2. Mechanical Seals Often used in pumps, mechanical seals consist of rotating and stationary components that create a seal by pressing against each other. They are particularly effective in high-pressure environments.

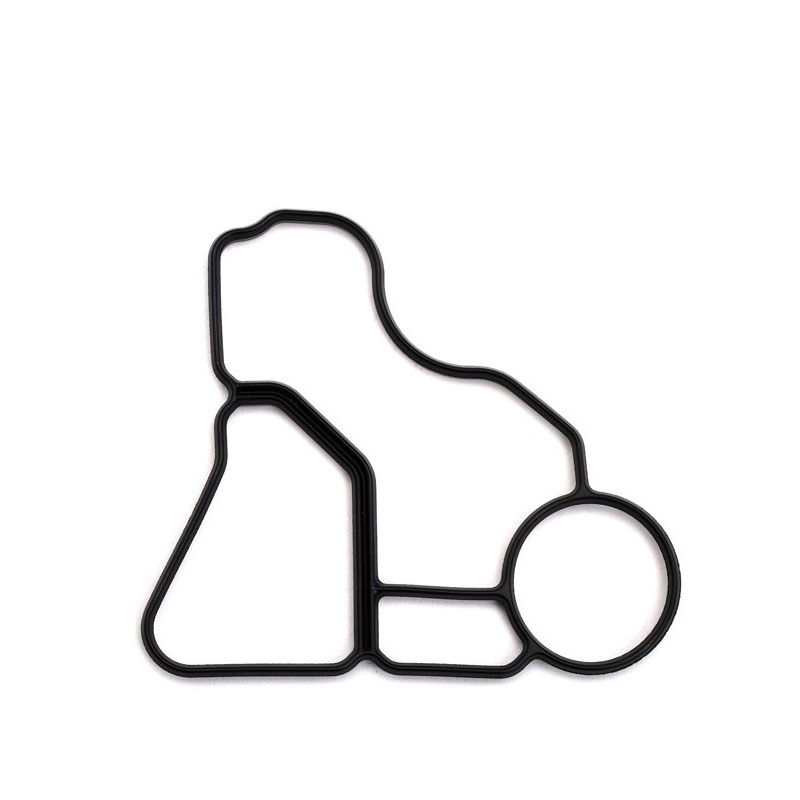

3. Gasket Seals Gaskets are flat seals that fill the space between two or more surfaces. They are essential for achieving a leak-proof barrier in flanged joints.

oil hub seal

4. Lip Seals These seals feature a flexible lip that maintains contact with a rotating shaft, preventing leaks while accommodating slight misalignments.

The Importance of Quality Sealing Solutions

Quality sealing solutions like the Oil Hub Seal are critical for several reasons

- Environmental Protection Oil spills can have devastating effects on the environment, highlighting the need for effective sealing solutions. By preventing leaks, Oil Hub Seals contribute to minimizing the risk of contamination and safeguarding ecosystems.

- Operational Efficiency Seals that function optimally reduce downtime. Leaks can lead to considerable interruptions in operations, resulting in lost revenue and increased maintenance costs. High-quality seals help ensure continuous operation.

- Safety Assurance The oil industry inherently involves risks, including fires and explosions. Proper sealing systems minimize the chances of hazardous leaks, thereby enhancing workplace safety for employees and nearby communities.

- Cost-Effectiveness Investing in top-notch sealing solutions can lead to long-term savings. While high-quality seals may have an initial higher cost, their durability and effectiveness reduce the frequency of replacements and repairs.

Conclusion

The Oil Hub Seal is an unsung hero in the oil and gas industry, performing a crucial function that is often overlooked. As the demand for oil continues to grow, ensuring the reliability and integrity of oil transportation and storage systems becomes increasingly important. By prioritizing quality sealing solutions, the industry can enhance operational efficiency, protect the environment, and ensure the safety of those who work within it. As technology advances, we can expect even further innovations in seal designs that will continue to support the ever-evolving needs of the oil industry.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories