Selecting the Right Gasket for Oil Tank Applications and Maintenance

Understanding Oil Tank Gaskets Importance, Types, and Maintenance

Oil tank gaskets are critical components in various industries, particularly in petroleum and chemical facilities. These gaskets ensure that oil tanks maintain their integrity, preventing leaks and contamination, while also playing a vital role in operational efficiency and safety.

What is an Oil Tank Gasket?

An oil tank gasket is a sealing device used to fill the space between two or more mating surfaces. It is designed to prevent the escape of liquids, gases, and vapors in oil storage tanks, ensuring that the contents remain contained and uncontaminated. Made from materials such as rubber, silicone, metal, or composite materials, the selection of the appropriate gasket material is vital for the gasket's performance and longevity, especially considering the corrosive nature of certain oils and additives.

Importance of Oil Tank Gaskets

The primary function of oil tank gaskets is to create a reliable seal. This is crucial for several reasons

1. Leak Prevention Oil spills can have catastrophic effects on the environment, leading to contamination of soil and water. A well-functioning gasket prevents leaks, protecting the environment and adhering to regulatory requirements.

2. Operational Efficiency Proper sealing ensures that the tanks function at their optimal capacity, preventing the loss of pressure and improving the overall efficiency of the storage system.

3. Safety Oil is flammable, and leaks can pose serious safety hazards. By utilizing effective gaskets, facilities can minimize the risk of fire and explosions.

4. Cost Savings Avoiding leaks and spills prevents costly cleanup operations and potential fines from regulatory bodies, thus contributing to long-term cost savings.

Types of Oil Tank Gaskets

There are several types of gaskets used in oil tanks, each suited for different applications and conditions

- Rubber Gaskets Commonly used for their flexibility and high resistance to degradation caused by various oils. They are suitable for standard applications but may not withstand extreme temperatures.

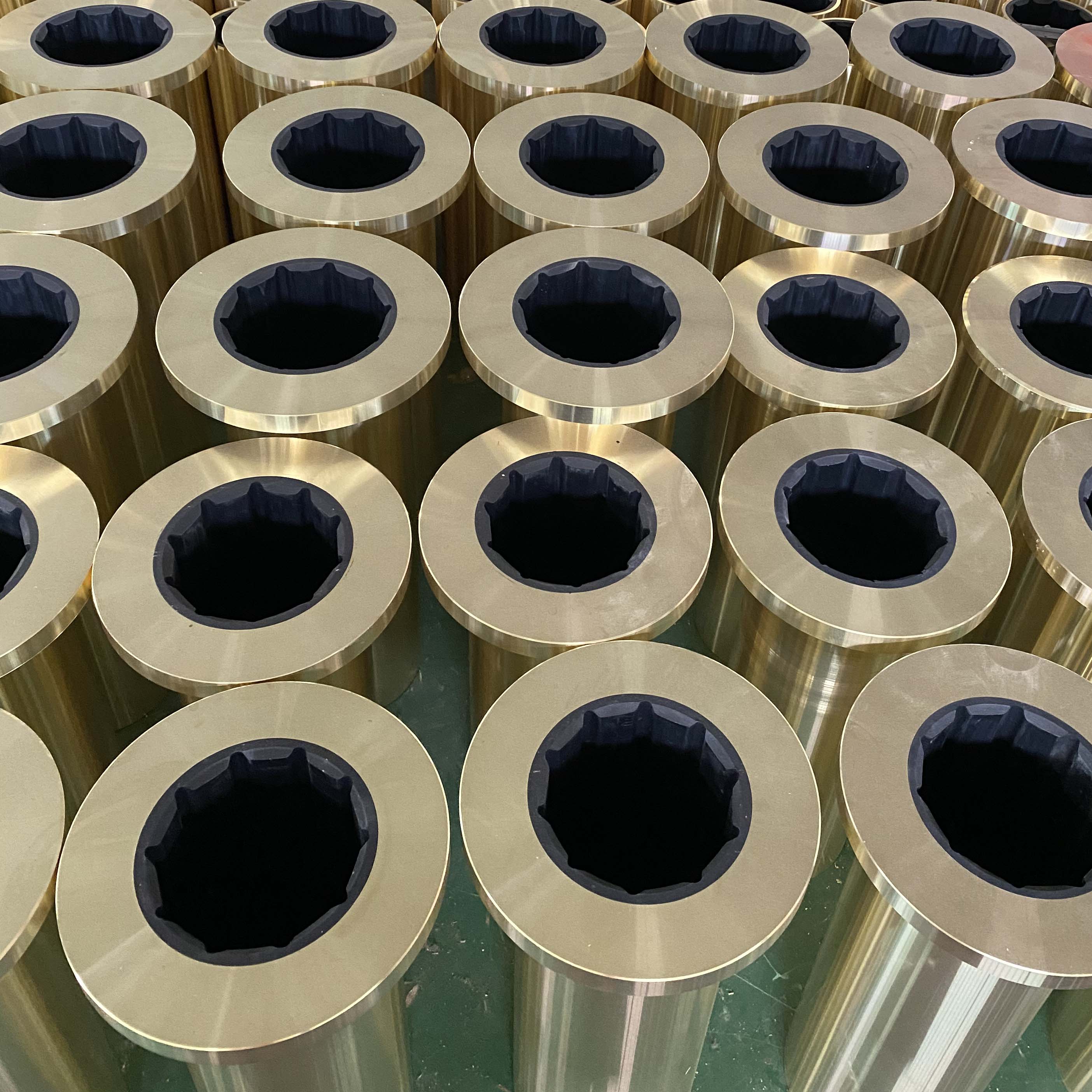

oil tank gasket

- Metal Gaskets Often used in high-pressure applications, these gaskets provide excellent durability and are capable of withstanding extreme temperatures and pressures. They are often designed in various shapes (e.g., ring, spiral wound) for increased efficiency.

- Composite Gaskets These gaskets combine different materials to enhance performance, typically featuring a tough outer layer and a softer inner layer to achieve a good seal while providing resistance to harsh chemicals.

- PTFE Gaskets Polytetrafluoroethylene gaskets are known for their chemical resistance and low friction, making them ideal for applications involving aggressive chemicals or where a precise seal is required.

Maintenance of Oil Tank Gaskets

Regular maintenance of oil tank gaskets is essential to ensure their effectiveness and longevity. Here are some best practices

1. Inspection Conduct regular inspections for signs of wear, damage, or degradation. Look for cracks, warping, or other signs of failure that could jeopardize the seal.

2. Replacement Gaskets should be replaced according to the manufacturer's recommendations or immediately if signs of leakage or wear are detected.

3. Cleaning Keep surfaces clean and free of contaminants before installation. Dirt or debris can prevent a proper seal and lead to leaks.

4. Correct Installation Ensure that gaskets are installed correctly, adhering to the manufacturer’s guidelines regarding torque and compression. Over-tightening can cause damage, while under-tightening may lead to leaks.

5. Material Compatibility Ensure that replacement gaskets are compatible with the type of oil being stored to avoid chemical reactions that could degrade the gasket material.

Conclusion

Oil tank gaskets play an indispensable role in the safety and efficiency of oil storage and transportation. Understanding their importance, types, and maintenance requirements can help facilities operate safely while minimizing environmental impacts. With appropriate care and proactive measures, the longevity and effectiveness of oil tank gaskets can be significantly enhanced, ensuring a reliable oil handling process.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories