Understanding Gearbox Output Shaft Seal Functions and Importance in Automotive Applications

Understanding Gearbox Output Shaft Seal Importance, Function, and Maintenance

The gearbox output shaft seal is a crucial component in the machinery and automotive industries, playing a vital role in the efficient operation and longevity of various mechanical systems. This seal is designed to prevent fluid leaks between the gearbox and the output shaft, ensuring that lubricants remain contained within the gearbox while keeping contaminants out.

Importance of the Gearbox Output Shaft Seal

The primary function of the gearbox output shaft seal is to ensure a tight seal around the shaft that emerges from the gearbox. This is important for several reasons

1. Preventing Fluid Leakage Gearboxes are filled with lubricants that minimize friction and heat generation during operation. A properly functioning output shaft seal prevents these lubricants from leaking out, maintaining the necessary levels for optimal performance.

2. Protecting Against Contaminants The seal acts as a barrier against dirt, dust, and debris. Contaminants can drastically affect the performance of a gearbox by introducing wear and tear or causing failures. An effective seal ensures that only clean lubricants circulate within the gearbox, extending its operational lifespan.

3. Enhancing Efficiency A sealed gearbox operates more efficiently. With proper lubrication maintained and without contamination, the gears can mesh smoothly, reducing energy loss and improving overall system performance.

4. Cost-Effectiveness Regularly replacing seals can prevent costly repairs or replacements of the entire gearbox. By ensuring that the fluid levels are maintained and that the gearbox is protected, a quality output shaft seal can help avoid extensive downtime and replacement costs.

Function of the Gearbox Output Shaft Seal

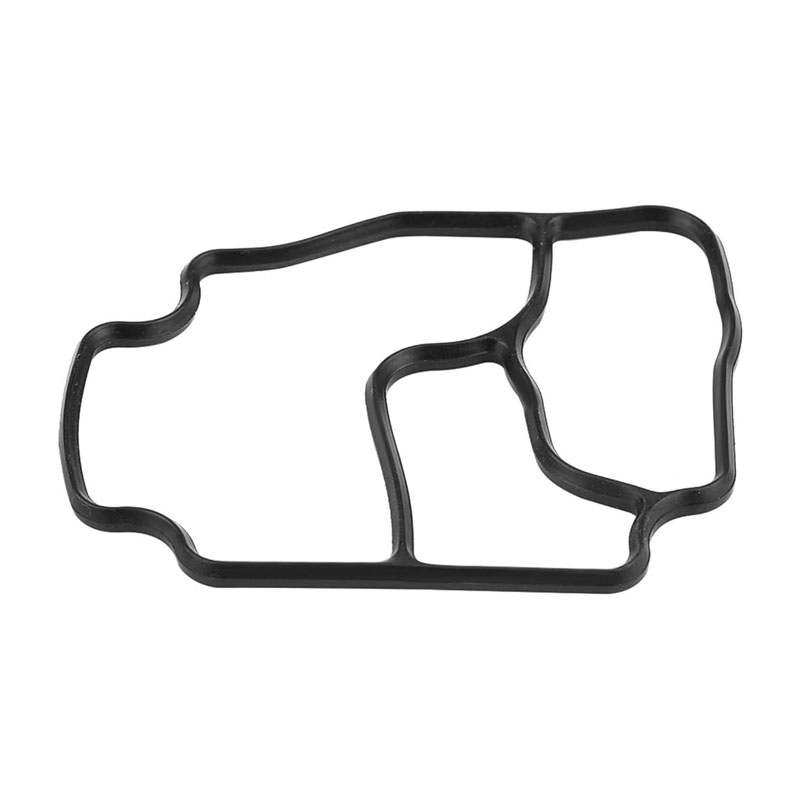

The gearbox output shaft seal functions by creating a barrier around the output shaft. It is typically made from materials like rubber, synthetic compounds, or other elastomers, which provide flexibility and resilience. As the output shaft rotates, the seal maintains contact with the shaft surface, adapting to its movement while preventing any leakage.

gearbox output shaft seal

The design of the seal may vary depending on the application. Some seals come with additional features, such as dust lips or spring-loaded designs, which help enhance their sealing capabilities and ensure they continue to perform effectively under various conditions.

Maintenance and Signs of Seal Failure

Given the critical role of the gearbox output shaft seal, regular maintenance and inspections are necessary to prevent failure. Here are some key points to consider

1. Regular Inspection Periodically check for any signs of fluid leakage around the gearbox output shaft. Even minor leaks could indicate that the seal is failing and may require attention.

2. Monitor Gearbox Performance If you notice changes in gearbox performance, such as unusual noises or increased operating temperatures, it might be a sign that the seal is compromised. Addressing these signs early can prevent larger issues down the line.

3. Consider Replacement If the seal does show signs of wear or damage, it’s important to replace it promptly. Replacement typically involves removing the old seal and installing a new one, ensuring that the sealing surfaces are clean and undamaged.

4. Environmental Considerations Be aware of the operating environment of the gearbox. Factors such as extreme temperatures, exposure to chemicals, or heavy dust can affect the seal's longevity. Selecting the appropriate seal material based on these conditions can enhance durability.

Conclusion

In summary, the gearbox output shaft seal plays an essential role in ensuring the efficiency and longevity of mechanical systems. Its ability to prevent fluid leakage and protect against contaminants not only enhances performance but also contributes to cost savings by reducing maintenance and repair expenses. Regular inspection and timely replacement are vital to maintaining gearbox integrity, ensuring that hydraulic and automotive systems continue to function optimally. Understanding the significance of this relatively small component can lead to better maintenance practices and ultimately, a more reliable mechanized operation.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories