Understanding the Functionality and Applications of Radial Oil Seals in Mechanical Systems

Understanding Radial Oil Seals A Comprehensive Overview

Radial oil seals, often referred to as rotary oil seals or shaft seals, are critical components in a variety of machinery and equipment, playing a pivotal role in preventing the leakage of lubricants while keeping contaminants at bay. These seals are widely utilized in automotive engines, gearboxes, hydraulic cylinders, and various industrial applications, ensuring smooth operation and extending the lifespan of machinery.

Structure and Functionality

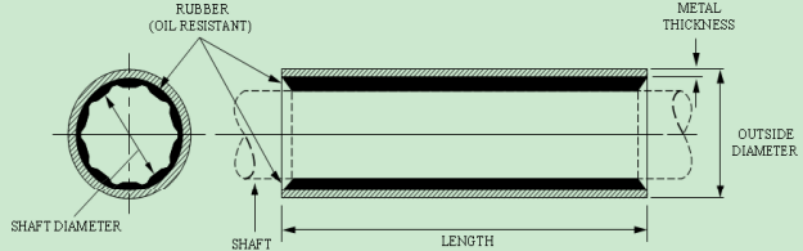

A radial oil seal typically consists of several key components the sealing element, the metal reinforcing ring, and sometimes a spring. The sealing element is usually made from elastomers such as Nitrile butadiene rubber (NBR), Fluoroelastomer, or Silicone, which provide excellent resistance to temperatures and chemical substances. The metal ring adds structural integrity, allowing the seal to withstand pressure and maintain its shape under operational conditions.

The primary function of a radial oil seal is to prevent oil or lubricant from leaking out of a housing while stopping contaminants like dirt and moisture from entering the system. They work on the principle of creating a contact seal against a rotating shaft, which minimizes the gap through which fluids can escape. This sealing action is crucial for maintaining the necessary lubrication within mechanical systems, ultimately leading to efficient operation and reduced wear on moving parts.

Applications of Radial Oil Seals

Radial oil seals are employed across multiple industries. In the automotive sector, they are found in engines, transmissions, and differentials, helping to maintain lubricating oils essential for efficient operation. In industrial machinery, these seals are vital in pumps, compressors, and hydraulic systems, where the proper functioning of the equipment is heavily dependent on preventing fluid loss and external contamination.

radial oil seal

Furthermore, radial oil seals are critical in aerospace and marine applications where reliability and durability are paramount. The ability of these seals to perform under extreme conditions, such as high pressures and temperatures, makes them indispensable in these fields.

Advantages and Considerations

One of the significant advantages of radial oil seals is their effectiveness in creating a tight seal that reduces the risk of leakage. They are relatively easy to install and can be designed to fit various shaft sizes and styles. Moreover, the customization of these seals allows for use across diverse applications, ensuring that industries can find suitable solutions for their specific needs.

However, selecting the right radial oil seal is crucial. Factors like the type of lubricant, the operating temperature, and the specific environmental conditions must be considered to ensure optimal performance and longevity. Premature seal failure often stems from inappropriate material selection, misalignment, or improper installation. Therefore, it’s essential for engineers and maintenance personnel to adhere to manufacturer guidelines and best practices during installation and operation.

Conclusion

In summary, radial oil seals are fundamental components that play a vital role in modern machinery and automotive systems. Their ability to manage lubrication and protect against contaminants directly influences the efficiency, performance, and durability of equipment. As technology evolves, ongoing innovations in materials and design will continue to enhance the effectiveness of radial oil seals, meeting the increasing demands of various industries. With proper understanding and care, these seals can significantly contribute to the overall reliability and functionality of mechanical systems, ensuring they run smoothly for years to come.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories