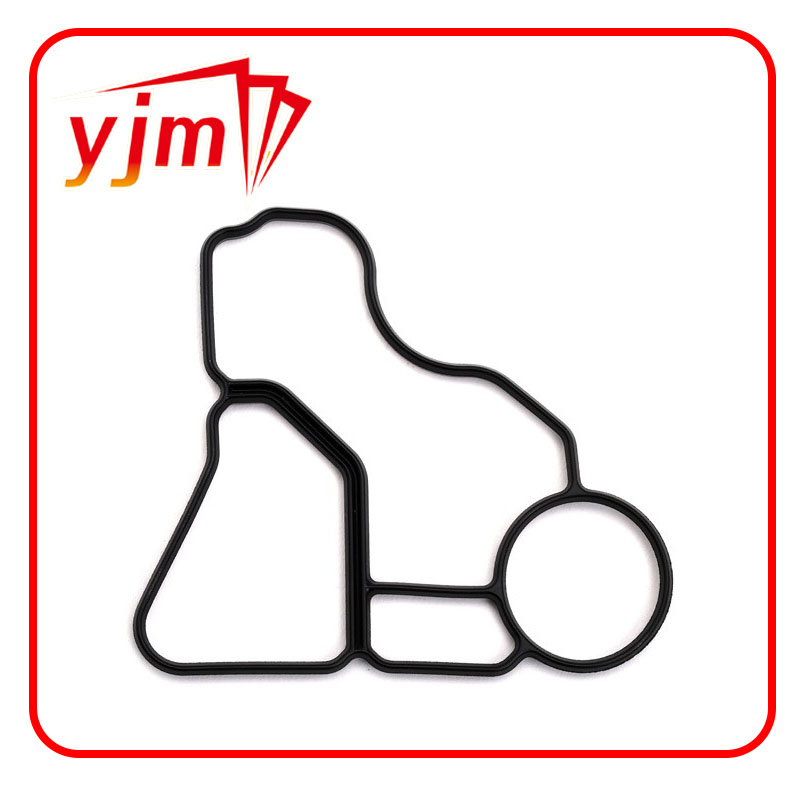

oil seal rubber

Understanding Oil Seal Rubber Essential Components in Mechanical Applications

Oil seal rubber, also known simply as oil seals, plays a crucial role in various mechanical applications by preventing leaks and ensuring the integrity of machinery. These seals are designed to contain lubricants, oils, and other fluids, protecting mechanical parts from contaminants such as dirt and moisture. As industries strive for higher efficiency and reliability, the demand for quality oil seal rubber has significantly increased.

Composition and Types of Oil Seal Rubber

Oil seals are typically made from elastomers, which are synthetic or natural rubber compounds that can stretch and recover their shape. Common materials used in the manufacture of oil seal rubber include nitrile rubber (NBR), silicone rubber (VMQ), and fluorocarbon rubber (FKM). Each type has specific properties that make it suitable for certain applications

1. Nitrile Rubber (NBR) NBR is one of the most widely used materials for oil seals, known for its excellent resistance to petroleum-based oils and fuels. It has good mechanical strength and durability, making it ideal for automotive and industrial settings where exposure to various fluids is expected.

2. Silicone Rubber (VMQ) Silicone rubber offers superior temperature resistance, making it suitable for high-temperature applications. While its oil resistance is not as high as NBR, its performance in extreme temperatures makes it invaluable in certain environments, such as engines or machinery that operate at elevated temperatures.

3. Fluorocarbon Rubber (FKM) This type of rubber is renowned for its exceptional chemical resistance, making it ideal for applications where seals must withstand harsh chemicals and high temperatures. It's commonly used in aerospace, automotive, and chemical processing industries.

Design and Functionality

The design of an oil seal typically includes a circular rubber element with a metal or plastic casing. The rubber part creates a flexible lip that embraces the shaft and prevents leakage. The metal casing provides structural support and maintains the seal's position within the assembly.

The functionality of oil seal rubber hinges on a few essential principles

- Fluid Containment The primary purpose of an oil seal is to retain lubricants within machinery while preventing external contaminants from entering. This helps maintain the lubrication system's efficiency, extending the lifespan of mechanical components.

oil seal rubber

- Pressure Resilience Oil seals must withstand internal pressure from the fluids they contain, as well as external pressure from the environment. A well-designed seal maintains its integrity even under dynamic conditions, ensuring reliable performance.

- Friction Reduction Oil seals minimize friction between moving parts, which can lead to wear and heat generation. By keeping lubricants contained around moving components, oil seals reduce wear and improve overall efficiency.

Applications

The applications of oil seal rubber are vast and varied. They are commonly found in

- Automotive Industry Used in engines, transmissions, and differentials to prevent oil leakage and maintain proper lubrication.

- Industrial Machinery Found in pumps, compressors, and gearboxes, oil seals protect internal components from contamination and ensure efficient operation.

- Aerospace Used in critical systems where leakage can be catastrophic, ensuring the reliability of hydraulic and fuel systems.

- Household Appliances Present in washing machines, dryers, and refrigerators, oil seals help maintain efficiency and prevent liquid leaks.

Conclusion

Oil seal rubber is a vital component in many mechanical systems, ensuring fluid containment and protection against environmental contaminants. With various materials and designs available, industries can select the optimal type of oil seal for their specific needs. As technology progresses and industries strive for greater efficiency, the role of oil seal rubber will continue to be significant, contributing to the reliability and longevity of machinery across various sectors. Understanding the importance and function of oil seal rubber ultimately helps in making informed decisions that enhance operational efficacy and reduce maintenance costs.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories