Understanding Mechanical Shaft Seals and Their Importance in Industrial Applications

Understanding Mechanical Shaft Seals Functionality, Types, and Applications

Mechanical shaft seals play a crucial role in ensuring the efficient operation of machinery by preventing the leakage of fluids along rotating shafts. These seals are essential components in various industrial applications, from automotive engines to pumps and compressors. This article delves into the functionality, types, and applications of mechanical shaft seals, highlighting their importance in modern engineering.

Functionality of Mechanical Shaft Seals

At its core, a mechanical shaft seal consists of two main components a stationary part and a rotating part. The stationary part is typically fixed to the housing, while the rotating part is attached to the shaft. As the shaft turns, the two parts create a sealing interface that minimizes fluid leakage. The primary function of a mechanical shaft seal is to retain lubricants or prevent the ingress of contaminants, thereby protecting the machinery from wear and failure.

A well-designed mechanical seal can withstand high pressures and temperatures, making it suitable for various conditions. These seals work by relying on a thin film of fluid that helps lubricate the sealing interface, reducing wear and prolonging the life of the mechanical seal. Additionally, they can accommodate axial and radial movements, allowing for the inevitable misalignments that occur in most rotating equipment.

Types of Mechanical Shaft Seals

Mechanical shaft seals come in various designs, catering to different operational needs. Here are some common types

1. Single Mechanical Seals These consist of a single set of sealing faces and are the most straightforward type of mechanical seal. They are suitable for applications involving low pressure and temperature.

2. Double Mechanical Seals Comprising two sets of sealing faces, double seals are often used in applications involving hazardous or toxic fluids. They provide an extra layer of protection by allowing a quench fluid to circulate between the two seals, reducing the risk of leakage.

3. Lip Seals These are typically used in applications with less demanding pressure and temperature conditions. They rely on a flexible lip to create a seal, making them an economical choice for many standard applications.

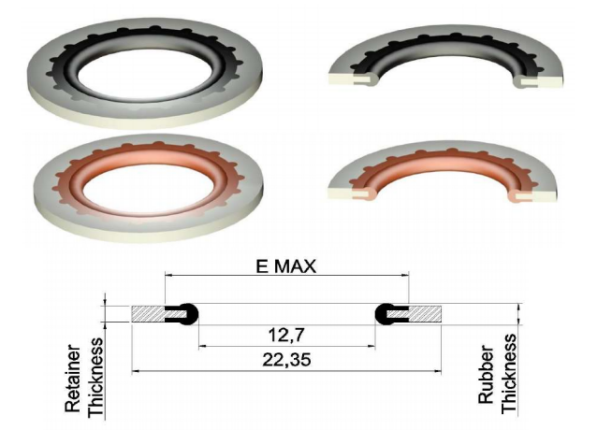

mechanical shaft seal

4. Cartridge Seals Designed for easy installation, cartridge seals come pre-assembled, eliminating the need for complicated adjustments during installation. They are often used in applications where maintenance and replacement are challenging.

Applications of Mechanical Shaft Seals

The versatility of mechanical shaft seals makes them applicable across numerous industries, including

- Automotive Mechanical seals are essential in preventing oil leaks from engines and gearboxes, ensuring efficient performance and longevity of vehicles.

- Oil and Gas In this industry, seals play a vital role in preventing the escape of fluids during drilling and production activities, which is crucial for safety and environmental protection.

- Chemical Processing Mechanical seals are vital in maintaining the integrity of chemical reactors and pipelines, preventing hazardous chemicals from leaking into the environment.

- Water and Wastewater Treatment Pumps used in these processes rely on robust mechanical seals to prevent leaks and ensure optimal operation, even under varying pressures and flow rates.

Conclusion

Mechanical shaft seals are indispensable in the functioning of many machines and systems across various industries. Understanding their functionality, types, and applications is essential for engineers and technicians to choose the right seal for specific applications, ultimately enhancing machinery performance and durability. By preventing leaks and protecting against contaminant ingress, these seals contribute significantly to the reliability and efficiency of modern engineering systems. As technology advances, the design and materials used in mechanical seals continue to evolve, promising even greater efficiency and reliability in the future.

-

Understanding Cassette Seals: A Durable Solution for Oil and Dirt Protection

News Apr.30,2025

-

Understanding and Maintaining the Polaris Ranger Front Differential

News Apr.30,2025

-

Understanding and Maintaining the Polaris Front Differential

News Apr.30,2025

-

Understanding and Maintaining the Crank Oil Seal for Engine Efficiency

News Apr.30,2025

-

Heavy Duty Seals: Durable Solutions for Home, Industrial, And Commercial Use

News Apr.30,2025

-

Auto Oil Seals: Protecting Your Engine from Leaks and Contamination

News Apr.30,2025

-

Essential Tools and Kits Every Car Owner Should Have

News Apr.29,2025

Products categories