Understanding the Importance of Flat Gaskets in Industrial Applications and Maintenance

Understanding Flat Gaskets Essential Components in Mechanical Seal Applications

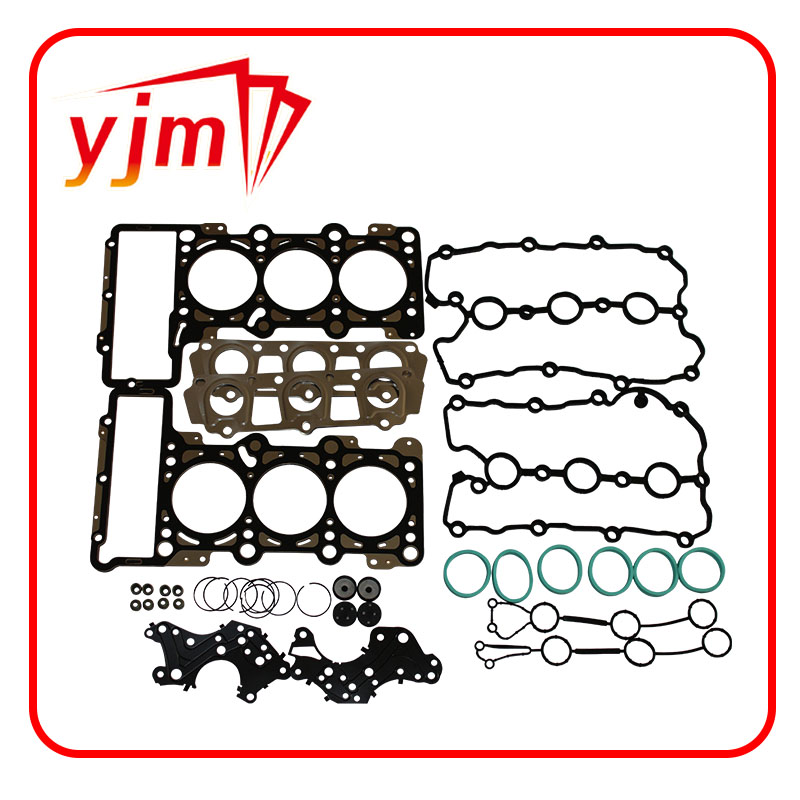

Flat gaskets are vital components in various mechanical systems, playing a critical role in ensuring the integrity of seals in machinery and piping systems. These simple, yet essential, devices are designed to fill the space between two or more mating surfaces, preventing leakage of fluids, gases, or prevent contamination. The importance of flat gaskets can be seen across numerous industries, including automotive, aerospace, oil and gas, and manufacturing.

Composition and Design

Flat gaskets can be made from a wide variety of materials, each chosen based on the specific requirements of the application. Common materials include rubber, cork, fiberglass, and various forms of metal, as well as composite materials that provide superior performance under high pressure and temperature conditions. The design of a flat gasket typically includes a geometrically defined shape that matches the contours of the surfaces it is intended to seal. The design must also accommodate the operational conditions, including pressure, temperature, and potential chemical exposure.

A crucial aspect of flat gasket design is the thickness. This factor directly influences the gasket's compressibility and the ability to fill imperfections in mating surfaces. When compressed, a gasket should create a tight seal that prevents leaks while being robust enough to withstand the forces exerted during operation.

Applications of Flat Gaskets

In automotive applications, flat gaskets are frequently found in engine components, such as valve covers and oil pans, where they play a vital role in preventing oil leaks and ensuring optimal engine performance. In the aerospace industry, gaskets are used in fuel systems and hydraulic circuits, where precise sealing is crucial for safety and efficiency.

flat gasket

The oil and gas industry relies heavily on flat gaskets for sealing pipelines and equipment. Given the hazardous nature of the materials transported through these pipelines, high-performance gaskets that can withstand extreme pressures and temperatures are essential. Additionally, the chemical resistance of gasket materials is critical in applications involving corrosive substances.

Maintenance and Replacement

Proper installation and maintenance of flat gaskets are essential for their effective performance. Over time, gaskets can degrade due to repeated heating and cooling cycles, exposure to chemicals, and mechanical stress. Signs of gasket failure include leaks, visible damage, or changes in the material properties. Regular inspection should be part of maintenance routines to ensure safe operation and prevent costly downtime.

When replacing flat gaskets, it is vital to choose the correct type and material for the specific application. The width, thickness, and overall dimensions must match the specifications of the existing gasket to ensure a proper seal. Failure to do so can lead to operational issues, including leaks and equipment damage.

Conclusion

Flat gaskets may appear to be simple components, but their role in various mechanical systems is undeniably significant. They are essential for maintaining the efficiency and safety of a wide range of applications, from everyday vehicles to complex aerospace systems. Understanding the properties, applications, and proper maintenance of flat gaskets is crucial for engineers and technicians alike, ensuring that these components continue to perform reliably in demanding environments. As industries evolve and face new challenges, the development of advanced gasket materials and designs will remain a key focus area in mechanical engineering, ensuring that sealing solutions are capable of meeting the rigorous demands of modern applications.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories