Similar Oil Seal Specifications for Enhanced Performance and Reliability in Machinery

The Importance of Oil Seals A Focus on 35 72 10 Oil Seal

Oil seals play a crucial role in the functionality and longevity of machinery in various industries, including automotive, manufacturing, and power generation. Among the numerous specifications available, the 35 72 10 oil seal stands out due to its unique dimensions and materials designed to withstand the harsh conditions often faced by machinery.

Understanding Oil Seals

At its core, an oil seal is designed to prevent the leakage of lubricants and to keep contaminants out of the machinery. It serves as a barrier against oil, grease, dirt, and other potential intruders that can cause wear and tear on crucial components. An effectively functioning oil seal not only protects the integrity of fluids but also enhances the overall performance of the machinery.

The Significance of the 35 72 10 Oil Seal

The designation 35 72 10 refers to the specific dimensions and attributes of this oil seal. The numbers typically denote the inner diameter, outer diameter, and width of the seal in millimeters. This particular oil seal, with its dimensions, is designed to fit specific applications, making it essential for manufacturers to select the right seal for their equipment.

One of the primary features of the 35 72 10 oil seal is its remarkable ability to withstand a wide range of temperatures and pressures

. Typically made from high-quality elastomers such as nitrile (NBR), fluoroelastomer (FKM), or polyurethane (PU), these seals provide excellent resistance to oil and various chemicals. This resistance ensures that they maintain their shape and functionality over time, which is vital for ensuring the smooth operation of machines.Applications and Benefits

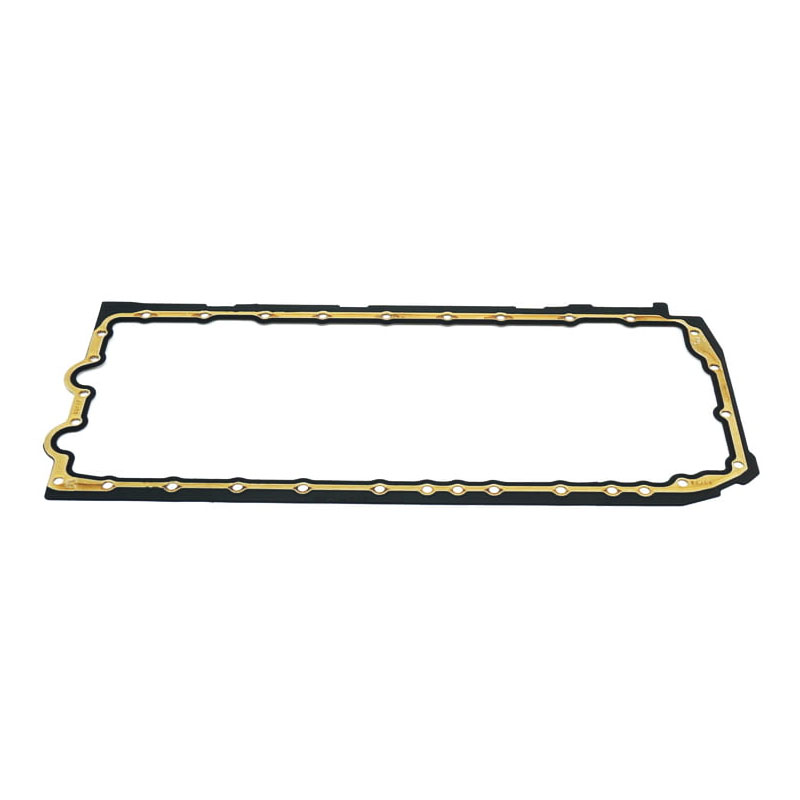

35 72 10 oil seal

The 35 72 10 oil seal is often used in various applications, including automotive engines, hydraulic pumps, and industrial machinery. By effectively sealing the spaces between rotating and stationary parts, these oil seals minimize friction, which can lead to overheating and premature wear of the components.

Another critical benefit of using the right oil seal, such as the 35 72 10, is its contribution to improved energy efficiency. Minimizing leaks helps in reducing fluid loss, ensuring that machinery operates at optimal performance levels. In today’s environmentally conscious world, reducing spills and enhancing the efficiency of machinery is critical for sustainable practices.

Installation and Maintenance

Proper installation of the oil seal is essential for its effectiveness. Even the best-quality seals can fail if not installed correctly. Machinery operators must ensure that the sealing surfaces are clean, smooth, and free from any debris before installing the oil seal. Additionally, the correct application of installation tools can prevent damage to the seal during fitting.

Conclusion

In conclusion, the 35 72 10 oil seal is more than just a simple piece of machinery; it is an integral component that ensures the smooth operation of engines and machines across various industries. Its design, crafted to meet specific dimensional requirements, showcases the importance of selecting the right seal for each unique application. Investing in high-quality oil seals can lead to significant benefits, including enhanced performance, improved energy efficiency, and prolonged machinery life.

As industries continue to evolve and the demands on machinery increase, understanding the role of oil seals will remain paramount in maintaining operational efficiency and reliability. In a world where every component counts, the 35 72 10 oil seal exemplifies the critical nature of efficient design and application in engineering solutions.

-

Understanding Polaris Front Differentials: Key Components for Off-Road Performance

News Jun.20,2025

-

Understanding Crankshaft Seals and Gaskets: Essential Components for Engine Longevity

News Jun.20,2025

-

Understanding Crankshaft Oil Seals: Vital Protection for Engine Performance

News Jun.20,2025

-

The Vital Role of Front and Rear Crankshaft Seals in Engine Protection

News Jun.20,2025

-

Rear Crankshaft Seals: Protecting Your Engine from the Back End

News Jun.20,2025

-

Crank Oil Seals: What They Do, How They Fail, and What They Cost

News Jun.20,2025

-

Understanding Oil Crush Washers: A Small Component with a Big Role in Vehicle Maintenance

News Jun.19,2025

Products categories