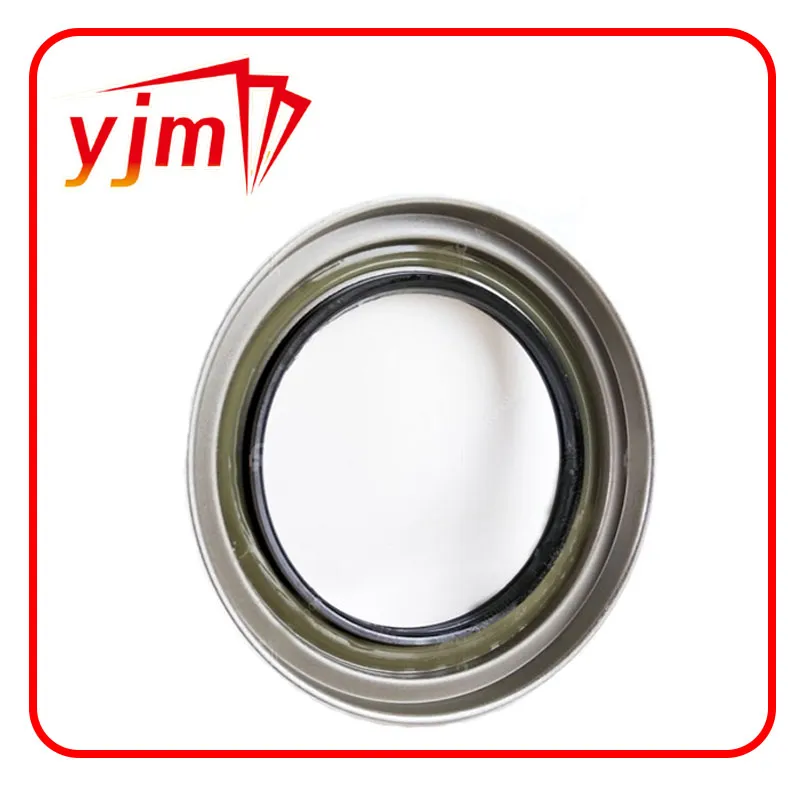

2418f475 oil seal

Understanding the 2418F475 Oil Seal A Crucial Component in Mechanical Systems

Oil seals, often overlooked yet essential components in mechanical systems, play a critical role in ensuring the efficient operation and longevity of machinery. Among the various types of oil seals, the 2418F475 oil seal stands out for its specific applications and features. This article will delve into the significance of this oil seal, its applications, construction, and maintenance.

What is an Oil Seal?

An oil seal, also known as a rotary shaft seal or grease seal, is a device used to seal the junction between a rotating shaft and a stationary housing. Its primary function is to prevent the leakage of lubricants, such as oil or grease, while also shielding the internal mechanism from contaminants like dirt, dust, and water. The importance of oil seals can be seen across various industries, including automotive, aerospace, manufacturing, and more.

Overview of the 2418F475 Oil Seal

The designation 2418F475 typically refers to the dimensions and material specifications of a particular oil seal. The numbers usually denote the inner diameter, outer diameter, and width in millimeters. For the 2418F475, the specific measurements may vary, but it usually indicates that it is designed to fit specific shaft sizes and housing dimensions for various applications.

This model is commonly used in rotating machinery, centrifugal pumps, gearboxes, and other components where rotary motion occurs. The construction of the seal often includes a rubber or elastomeric material, which provides flexibility and elasticity, making it suitable for various operational conditions, including temperature and pressure variations.

Construction and Features

The 2418F475 oil seal is typically constructed from high-quality materials that offer resilience and compatibility with various lubricants. Common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), and polyurethane. Each of these materials provides different advantages, such as resistance to high temperatures, oils, and chemicals.

This oil seal features a metal or rubber outer casing that helps in maintaining its shape and allows for easy installation. The inner lip, which comes into contact with the shaft, is designed to create a tight seal, preventing the leakage of lubricants while allowing for minimal friction. This design ensures that the seal can withstand the repetitive motion without wearing out quickly.

2418f475 oil seal

Applications of the 2418F475 Oil Seal

The 2418F475 oil seal is versatile and is utilized in a range of applications. Some of the most common uses include

1. Automotive Industry In vehicles, oil seals are used in engines, transmissions, and differentials to prevent oil leaks and protect components from dirt and contaminants.

2. Industrial Machinery Equipment like pumps, compressors, and conveyors often use this oil seal to maintain lubrication and prevent the ingress of debris, which could lead to mechanical failures.

3. Aerospace and Aviation Ensuring the proper sealing in aircraft engines and systems is crucial for safety and efficiency, making the 2418F475 oil seal a vital component in these applications.

Maintenance Tips

To ensure the longevity and performance of the 2418F475 oil seal, regular maintenance and inspection are essential. Here are some maintenance tips

- Regular Inspection Periodically check for signs of wear, deformation, or leakage around the seal. - Proper Installation Ensure that the oil seal is installed correctly, following the manufacturer’s specifications to avoid misalignment. - Use Compatible Lubricants Always use lubricants that are compatible with the seal material to prevent degradation.

Conclusion

The 2418F475 oil seal is a crucial element in various mechanical systems, ensuring efficiency and longevity by preventing leakage and protecting against contaminants. Understanding its applications, construction, and maintenance can help improve machinery performance and reduce repair costs. Regular inspections and proper care are essential for maximizing the lifespan of the oil seal, making it a worthy investment for any industry reliant on mechanical operations. As technology advances, oil seals will continue to evolve, underscoring their importance in modern engineering and manufacturing.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories