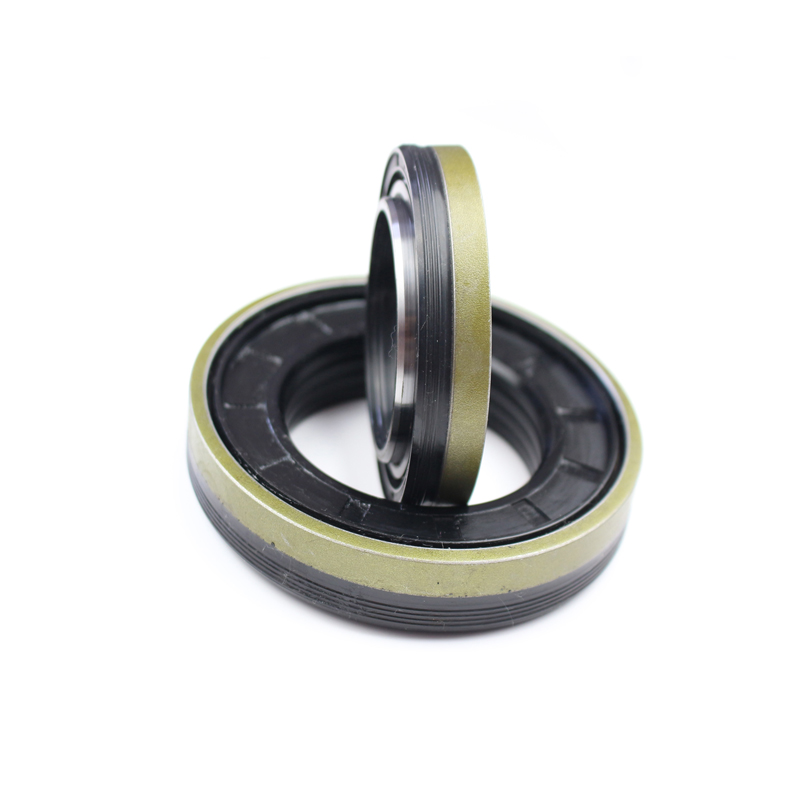

Durable Cassette Seals & Oil Seals for Heavy Duty Applications

Innovating Sealing Solutions: The Advanced Cassette Seal

In demanding industrial environments, the integrity of rotating machinery hinges significantly on effective sealing mechanisms. Among the most critical components are advanced sealing solutions designed to protect bearings and other sensitive parts from contaminants while retaining lubrication. The cassette seal stands out as a superior, self-contained sealing unit, engineered to provide unparalleled protection against dust, dirt, water, and other abrasives, extending the operational life of equipment. Its robust multi-lip design and integrated metal housing simplify installation and enhance reliability, making it an indispensable component across various heavy-duty applications. This comprehensive guide delves into the technical intricacies, market trends, and practical applications of these vital seals, highlighting their profound impact on operational efficiency and longevity.

The industrial landscape is continuously evolving, with a growing emphasis on minimizing downtime, reducing maintenance costs, and improving environmental performance. This trend directly fuels the demand for high-performance sealing technologies like the cassette seal. Market analysis indicates a steady growth in the global industrial seals market, driven by expansions in manufacturing, automotive, agriculture, and construction sectors. As machinery operates at higher speeds and under more extreme conditions, the need for seals that can withstand increased pressure, temperature fluctuations, and aggressive media becomes paramount. Manufacturers are increasingly seeking solutions that offer extended service intervals and enhanced reliability, positioning the cassette seal as a preferred choice for critical applications where traditional seals fall short.

Technical Specifications and Performance Parameters

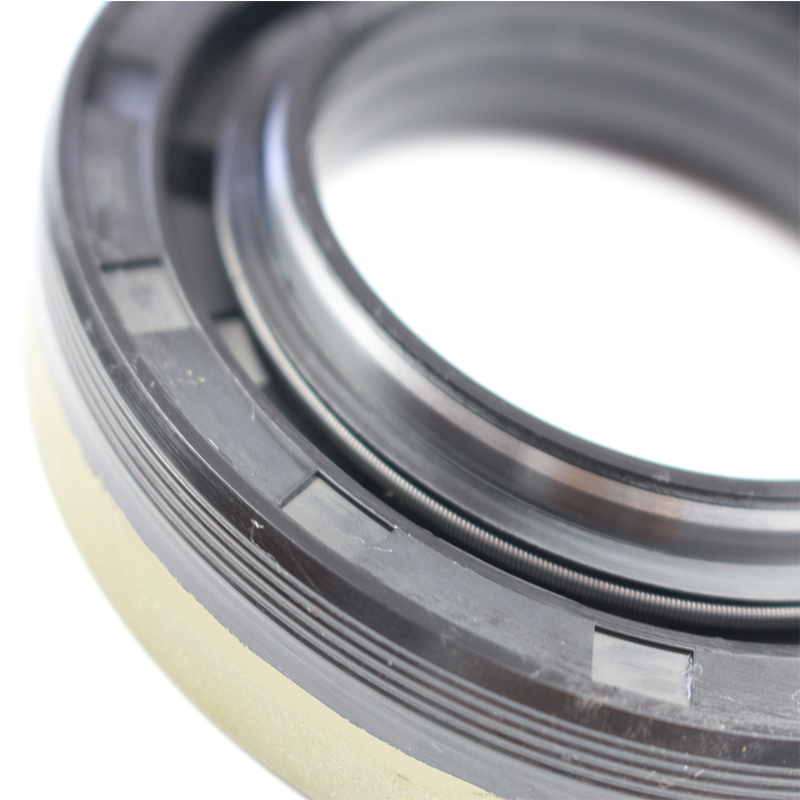

Understanding the technical specifications of a cassette oil seal is crucial for optimal selection and application. These seals are not merely simple barriers; they are precision-engineered components designed to operate under specific conditions. Key parameters include material composition, operating temperature range, pressure resistance, and shaft diameter compatibility. The multi-lip design often incorporates primary and secondary sealing lips, with integrated dirt exclusion features and a hydrodynamic pumping action that aids in lubricant retention while expelling contaminants. High-performance elastomeric compounds, such as NBR, HNBR, FKM, and ACM, are selected based on the specific media compatibility, temperature requirements, and resistance to wear and tear.

| Parameter | Typical Range/Value | Description/Notes |

|---|---|---|

| Shaft Diameter (d1) | 50 mm to 300 mm+ | Common sizes for heavy-duty applications. |

| Outer Diameter (D) | 70 mm to 350 mm+ | Corresponds to housing bore. |

| Width (b) | 15 mm to 40 mm+ | Axial space requirement. |

| Operating Temperature | -40°C to +110°C (NBR) -30°C to +180°C (FKM) |

Varies significantly by elastomer material. |

| Max. Peripheral Speed | Up to 10 m/s (higher with special designs) | Critical for shaft wear and seal life. |

| Materials | NBR, HNBR, FKM, ACM (Elastomer) Steel, Stainless Steel (Housing) |

Selected for chemical compatibility and durability. |

| Expected Lifespan | 2-5 years under optimal conditions | Significantly longer than traditional seals due to design. |

This table provides a general overview; specific cassette seal catalog entries will detail precise dimensions and material specifications to match exact application requirements. The design of each cassette seal ensures that the sealing lips run on a separate, hardened counter-surface integrated within the seal itself, rather than directly on the shaft. This innovative feature prevents shaft wear, a common issue with traditional oil seals, and simplifies installation since no special shaft preparation or finishing is required, leading to substantial savings in maintenance time and costs.

Manufacturing Process and Quality Assurance

The production of high-quality cassette seals involves a meticulous multi-stage manufacturing process, combining advanced material science with precision engineering. It typically begins with the selection of premium-grade elastomeric materials and high-strength steels. The manufacturing process often involves precision molding for the elastomeric components, ensuring dimensional accuracy and consistent mechanical properties. The steel housing components may undergo processes like stamping, deep drawing, or CNC machining, followed by hardening treatments to achieve optimal wear resistance and structural integrity.

Assembly of the different components (elastomer lips, metal housing, and sometimes springs) is performed in a clean environment, often automated to ensure consistency and minimize human error. Post-assembly, each cassette seal undergoes rigorous quality control. This includes dimensional checks, material integrity tests, lip deflection tests, and rotational leak tests. Adherence to international standards such as ISO 9001 for quality management and industry-specific ANSI standards for performance is paramount. Continuous process monitoring and statistical process control (SPC) techniques are employed to maintain tight tolerances and ensure every seal meets stringent performance criteria, guaranteeing a robust and reliable product with an extended service life under even the most challenging conditions.

Key Technical Advantages and Features

The inherent design of a cassette seal provides several distinct advantages over conventional radial shaft seals. Its multi-lip arrangement, often featuring three or more sealing lips, provides superior protection against both internal lubricant leakage and external contaminant ingress. This complex labyrinth design effectively traps contaminants, preventing them from reaching the bearing cavity, thus significantly extending bearing life. The integrated counter-surface eliminates the need for shaft re-machining or wear sleeves, simplifying maintenance and reducing repair costs.

Furthermore, the pre-assembled unit design ensures consistent performance and minimizes installation errors, which are common causes of premature seal failure. This ease of installation translates directly into reduced downtime. From an operational perspective, these seals contribute to significant energy savings by minimizing frictional losses compared to traditional sealing solutions, leading to cooler running temperatures and lower power consumption. Their robust construction also provides excellent anti-corrosion properties, especially when specialized materials like stainless steel are used for the housing, ensuring long-term reliability in harsh chemical or wet environments. The extended service life offered by these advanced seals directly translates into lower total cost of ownership (TCO) for industrial machinery.

Diverse Application Scenarios

The versatility and robust performance of cassette seals make them ideal for a wide array of heavy-duty industrial applications where reliability is non-negotiable. They are predominantly found in sectors characterized by severe operating conditions, high dust exposure, and demanding mechanical loads. In the agricultural sector, for instance, they are vital for protecting wheel hubs, gearboxes, and axles in tractors, combines, and other farm machinery, where exposure to soil, water, and crop debris is constant. The construction industry heavily relies on these seals for excavators, loaders, bulldozers, and other heavy equipment, ensuring uninterrupted operation in dusty, muddy environments.

Beyond these, cassette seals are indispensable in the truck and bus industry for wheel ends and drivelines, contributing to vehicle safety and efficiency. The mining sector benefits immensely from their durability in conveyor systems, crushers, and heavy-duty vehicles, resisting extreme abrasive conditions. Furthermore, in general industrial machinery, including gearboxes, industrial pumps, and rolling mills in steel, cement, and paper mills, these seals provide critical protection, preventing costly failures and ensuring continuous production. Their ability to perform consistently in harsh environments makes them a cornerstone of modern industrial reliability.

Customization Solutions and Services

While standard cassette seals address a broad range of applications, many industrial scenarios present unique challenges that necessitate customized sealing solutions. A reputable cassette seals manufacturer excels in providing bespoke designs tailored to specific operational parameters, environmental factors, and machinery requirements. This includes variations in material compounds to resist particular chemicals or extreme temperatures, modifications to the lip design for enhanced sealing performance in highly contaminated environments, or adjustments to the overall dimensions to fit non-standard housing bores or shaft diameters.

The customization process typically involves a detailed consultation, engineering analysis using CAD and FEA (Finite Element Analysis) tools, rapid prototyping, and extensive testing to validate performance before mass production. This collaborative approach ensures that the custom cassette oil seal not only fits perfectly but also delivers optimal performance and extends the lifespan of the equipment it protects, addressing niche market demands and specialized industrial needs effectively. By engaging with an experienced manufacturer, businesses can achieve sealing solutions that precisely meet their unique and challenging requirements.

Real-World Application Cases and Success Stories

The tangible benefits of deploying high-quality cassette seals are best illustrated through real-world application cases. For instance, a major agricultural equipment manufacturer faced recurring bearing failures in their tractor axles due to severe dust ingress during harvesting seasons. After switching from traditional oil seals to advanced cassette seals, they reported a 70% reduction in bearing replacement frequency and a significant decrease in lubricant consumption over a two-year period. This directly translated into substantial savings in maintenance costs and a dramatic improvement in equipment uptime during critical operational windows.

Another compelling example comes from the heavy-duty truck industry. A logistics company experienced persistent premature wear on their truck wheel bearings, leading to unexpected roadside breakdowns and costly tow services. Implementing a robust cassette oil seal solution, specifically designed for harsh road conditions and varying temperatures, resulted in an average extension of wheel bearing life by over 150,000 miles per vehicle. This not only enhanced fleet reliability and safety but also significantly lowered operational expenses by reducing unscheduled repairs and extending maintenance intervals. These cases underscore the critical role of advanced sealing technology in boosting productivity and profitability for B2B enterprises.

Frequently Asked Questions (FAQ)

Q1: What makes a cassette seal superior to a traditional oil seal?

A cassette seal features a multi-lip design (typically 3-5 lips) and an integrated counter-surface, meaning the sealing lips run on a hardened surface within the seal itself, not on the shaft. This prevents shaft wear, simplifies installation, and offers superior protection against contaminants and lubricant leakage compared to a single-lip traditional oil seal, drastically extending bearing and seal life.

Q2: What is the typical lifespan of a cassette oil seal?

Under optimal operating conditions and proper installation, a high-quality cassette oil seal can last significantly longer than traditional seals, typically ranging from 2 to 5 years. This extended lifespan is a direct result of its robust design and ability to withstand harsh environmental conditions and high operational demands.

Q3: Can these seals be customized for specific applications?

Yes, absolutely. A professional cassette seals manufacturer often provides extensive customization options. This includes varying material compounds for chemical resistance or extreme temperatures, adjusting lip configurations for specialized sealing challenges, and bespoke sizing to fit unique machinery specifications. Tailored solutions ensure optimal performance for niche or highly demanding applications.

Trust and Partnership: Your Reliable Cassette Seals Manufacturer

Choosing the right cassette seals manufacturer is paramount for ensuring consistent quality, reliable supply, and expert technical support. A reputable partner should demonstrate a long-standing commitment to quality, evidenced by certifications such as ISO 9001, and extensive experience serving diverse industries. Our commitment to excellence is reflected in our rigorous testing protocols, adherence to international standards, and a proven track record of delivering high-performance sealing solutions for many years. We provide transparent communication regarding product specifications and performance.

Our services extend beyond mere product delivery. We offer comprehensive customer support, including technical consultations, application engineering assistance, and after-sales service. Our standard delivery cycles are typically 4-6 weeks for custom orders and 1-2 weeks for stock items, ensuring your operations remain uninterrupted. All our products come with a 12-month quality assurance warranty, underscoring our confidence in the durability and performance of our cassette seal offerings. We are dedicated to building long-term partnerships based on trust, reliability, and mutual success.

Conclusion

The importance of the cassette seal in modern industrial machinery cannot be overstated. As a sophisticated, self-contained sealing unit, it offers unparalleled protection against contaminants and ensures superior lubricant retention, directly contributing to extended equipment lifespan, reduced maintenance costs, and improved operational efficiency. From heavy-duty agricultural machinery to industrial pumps and truck axles, the versatile applications and proven benefits of these seals underscore their critical role in today's demanding industrial environments. Investing in high-quality cassette seal solutions is a strategic decision that pays dividends in reliability, performance, and overall total cost of ownership, securing the longevity and productivity of valuable assets.

References

- ISO 9001:2015 Quality management systems – Requirements. International Organization for Standardization.

- SKF. (2014). Sealing Solutions Handbook. SKF Group.

- Freudenberg Sealing Technologies. (2018). Simmerring® Cassette Seals – Technical Manual.

- Brown, B. & Smith, J. (2020). Advanced Sealing Technologies in Heavy Machinery. Journal of Tribology and Lubrication Engineering, 76(2), 123-135.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories