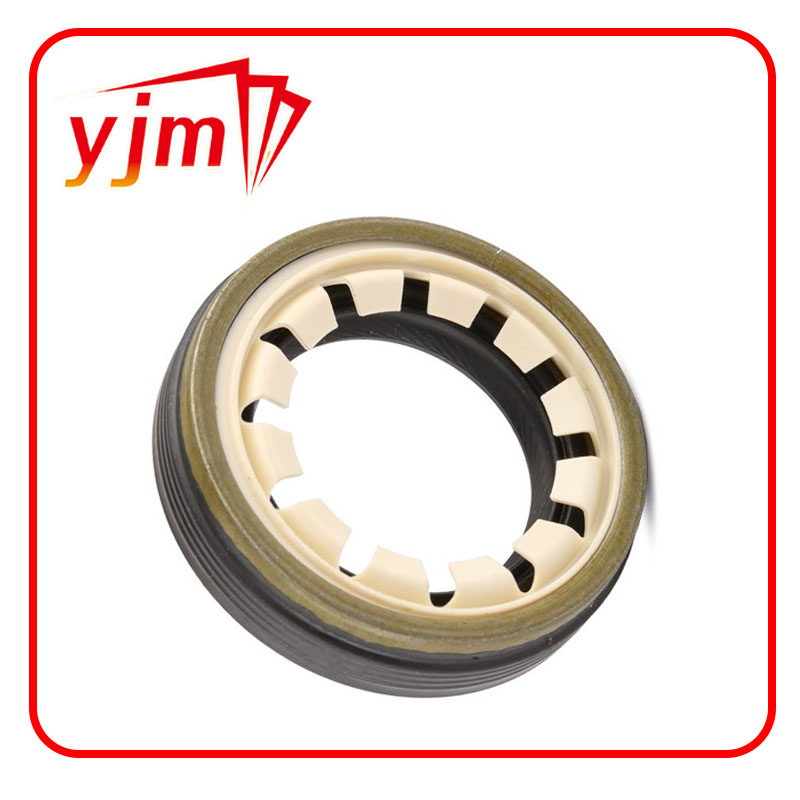

cfw seals

The Importance of CFW Seals in Modern Industry

In today’s fast-paced industrial landscape, the integrity of machinery and equipment is paramount. One critical component that often goes unnoticed but plays a vital role in maintaining operational efficiency and safety is the seal — particularly, CFW seals. CFW seals, or controlled fluid dynamic seals, are specifically engineered to perform effectively in various industrial applications. Understanding their function, benefits, and applications is essential for professionals in the field.

What are CFW Seals?

CFW seals are designed to manage the flow of fluids in systems where maintaining pressure and preventing leakage is crucial. These seals are crafted from advanced materials that can withstand extreme temperatures, pressures, and chemical exposures. Their design balances hydrodynamic and hydrostatic forces, ensuring minimal friction and wear over time.

In essence, CFW seals function to create a barrier that prevents fluids from escaping or contaminating the environment. This capability is vital in sectors such as oil and gas, pharmaceuticals, food processing, and water treatment, where safety and regulatory compliance are significant concerns.

The Benefits of CFW Seals

One of the primary advantages of CFW seals is their ability to enhance the longevity of machinery. By preventing fluid leakage, they protect against costly downtime, which can severely impact productivity. Regular maintenance and replacement of components can often be a drain on resources. By investing in quality CFW seals, companies can reduce these operational costs significantly.

In addition to cost-effectiveness, CFW seals also enhance safety in industrial operations. Fluid leaks can pose environmental hazards, lead to workplace accidents, and result in compliance violations. By employing high-quality seals, businesses demonstrate their commitment to safety and environmental responsibility, which is increasingly essential in today's market.

Moreover, CFW seals contribute to energy efficiency. Leaking fluids not only represent a loss of material but can also lead to increased energy consumption. By ensuring that systems operate as designed, these seals help improve overall energy efficiency, aligning with modern initiatives aimed at sustainability.

cfw seals

Applications of CFW Seals

The versatility of CFW seals allows them to be utilized in various applications across multiple industries. In the oil and gas industry, for instance, these seals help in maintaining pressure in pipelines, preventing not only economic loss but also environmental disasters that can arise from leaks.

In the pharmaceutical sector, precision is key. CFW seals are designed to prevent contamination, maintaining the integrity of sensitive substances during processing. Since pharmaceutical products require stringent adherence to safety standards, the role of reliable seals cannot be overstated.

In the food processing industry, CFW seals ensure that food products remain uncontaminated and safe for consumption. By maintaining a clean environment and preventing leaks, these seals contribute to the overall hygiene and safety of food production.

Finally, in water treatment facilities, CFW seals help manage the movement of fluids, ensuring that operations run smoothly and efficiently. Given the critical nature of water supply systems, the reliability of these seals is essential to prevent any disruptions or contamination in the supply chain.

Conclusion

CFW seals are an indispensable element in the modern industrial toolkit. Their role in enhancing operational efficiency, increasing safety, and promoting sustainability is invaluable. As industries continue to evolve and the demand for reliable and efficient operations grows, the importance of high-quality seals like CFW cannot be overlooked.

Professionals in the field need to pay attention to the specifications, materials, and compatibility of seals within their systems. Investing in CFW seals is not just about purchasing a component; it is about fostering a culture of safety, efficiency, and responsibility in industrial operations. As technology advances and industries strive for efficiency, the future of CFW seals appears bright, underscoring their critical role across various sectors.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories