Understanding the Functionality and Applications of Radial Shaft Seal Rings in Machinery

Understanding Radial Shaft Seal Rings Importance and Applications

Radial shaft seal rings, often referred to simply as shaft seals, play a critical role in various mechanical systems. They are designed to prevent the leakage of fluids, protect internal components from external contaminants, and maintain the efficiency of rotating machinery. In this article, we will explore the structure, types, functions, and applications of radial shaft seal rings, emphasizing their significance in modern engineering and manufacturing.

Structure and Composition

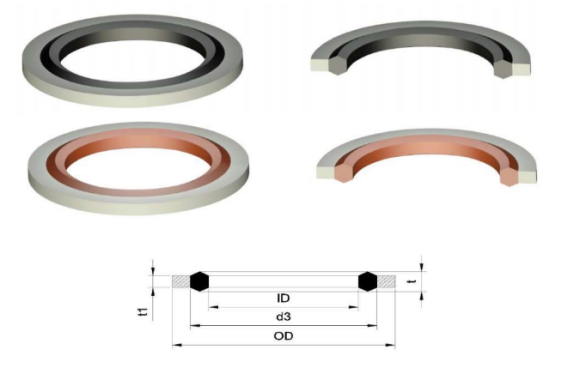

A radial shaft seal typically consists of a few key components the elastomeric sealing element, a metal or fabric reinforcement, and a retainer. The elastomer serves as the primary seal, providing flexibility and durability to withstand pressures and temperatures. The reinforcement adds strength and stability, ensuring the seal maintains its shape and effectiveness over time. The retainer holds the seal in place, facilitating installation and alignment within the housing.

Types of Radial Shaft Seals

Radial shaft seal rings come in various types, each designed for specific applications and environments. The two most common types are

1. Single-lip Seals These seals feature one sealing lip that contacts the shaft directly. They are suitable for low-pressure applications where the risk of contamination is relatively low.

2. Double-lip Seals These seals have two sealing lips, providing an additional barrier against leakage and contaminants. They are often used in more demanding conditions, such as those involving high pressures or exposure to harsh chemicals.

Additionally, materials used to manufacture radial seals can vary based on their intended use, including vinyl, nitrile, and silicone elastomers, each chosen for their specific tolerance to temperature, chemicals, and wear.

Functions of Radial Shaft Seals

The primary functions of radial shaft seals include

- Leak Prevention By sealing the gap between the rotating shaft and the static housing, these seals prevent the escape of lubricants and fluids, which is vital for maintaining the efficiency of machinery

.radial shaft seal ring

- Contamination Resistance Radial shaft seals protect the internal components of machines from dirt, dust, and other contaminants that could lead to wear and tear.

- Pressure Retention In certain applications, such as hydraulics, maintaining internal pressure is critical. Radial shaft seals help retain this pressure by providing a tight seal that minimizes leakage.

- Vibration Reduction Well-designed seals can also reduce vibrations within mechanical systems, contributing to smoother operation and prolonging the lifespan of the equipment.

Applications

Radial shaft seal rings are found in a wide range of applications across various industries. Some common examples include

- Automotive Industry In vehicles, radial shaft seals are used in engines, transmissions, and wheel hubs to prevent fluid leaks and keep out contaminants.

- Industrial Machinery Heavy machinery such as pumps, gearboxes, and hydraulic systems rely on these seals for reliable operation.

- Aerospace Aircraft systems use radial seals to ensure safety and efficiency in harsh environments.

- Home Appliances Washing machines, refrigerators, and other appliances utilize radial shaft seals to improve performance and longevity.

Conclusion

In conclusion, radial shaft seal rings are an indispensable component in mechanical engineering, serving critical functions that enhance the reliability and efficiency of various systems. Their ability to prevent leaks, resist contamination, and withstand varying pressures makes them valuable in numerous industries. As technology advances and new materials are developed, the efficacy and versatility of radial shaft seals will continue to evolve, helping engineers solve complex challenges in machinery design and functionality. Understanding the importance of these seals is essential for anyone involved in manufacturing, maintenance, or engineering fields.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories