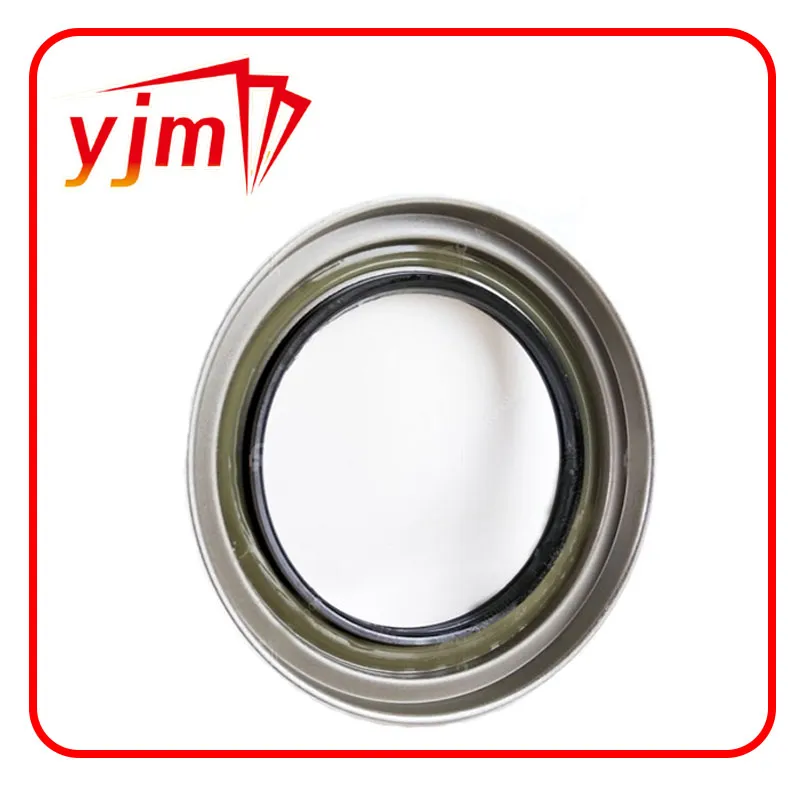

40 80 10 oil seal

The Importance of Oil Seals Focusing on 40% 80% 10% Specifications

Oil seals, also known as shaft seals or rotary seals, play an essential role in numerous mechanical applications. They are designed to prevent the leakage of lubricants and the ingress of contaminants, ensuring smooth operation and longevity of machinery. When it comes to the specifics of oil seals, particularly, the combination of 40%, 80%, and 10% in their specifications will be a focal point of our exploration in this piece.

Understanding Oil Seal Characteristics

The values of 40%, 80%, and 10% can represent various parameters such as material composition, performance characteristics, and environmental adaptability of oil seals. The first number, 40%, might refer to the content of a particular polymer or elastomer in the seal material. For example, a seal composition with 40% of a specific synthetic rubber might offer enhanced resilience and resistance to wear over time.

The second figure, 80%, can denote the sealing capability or pressure range the oil seal can effectively handle. In industrial applications, seals that can maintain their integrity under high pressure are critical. An oil seal rated at 80% effectiveness under a certain pressure indicates a strong performance level, making it suitable for demanding environments such as automotive engines or heavy machinery.

Lastly, the third number, 10%, might represent the operational temperature tolerance. Many oil seals function optimally within a certain temperature range, and a seal with a 10% variance may indicate that it can perform in temperatures slightly lower or higher than its optimal rating.

Applications of Oil Seals

With their staggering importance in machinery, oil seals find applications in a wide array of industries, including automotive, aerospace, manufacturing, and marine. In automotive applications, oil seals prevent engine oil from leaking out and keep contaminants from entering the engine components. They are crucial for maintaining fluid levels in gearboxes, differentials, and hydraulic systems.

40 80 10 oil seal

In aerospace, the reliability of seals is paramount. The operational environments faced by aircraft require seals that not only withstand extreme temperatures but also provide impeccable sealing under pressure changes during flight. A slight failure in seal integrity can lead to system malfunctions and could endanger both the aircraft and its passengers.

Furthermore, in the manufacturing sector, oil seals are employed in conveyors, pumps, and various processing equipment. They ensure that lubricants remain effective while preventing unwanted debris from damaging internal components. The durability and efficiency of machines heavily depend on the quality of these sealing components.

Selecting the Right Oil Seal

Choosing the appropriate oil seal is crucial for the longevity and efficiency of the equipment. When considering seals with 40% composition, 80% effectiveness, and 10% temperature tolerances, it becomes essential to consult manufacturers’ specifications and performance data. Different applications may necessitate different seal characteristics—finding a seal that aligns well with the operational demands is key.

Additionally, considerations such as chemical compatibility with fluids being sealed, mechanical properties, and installation requirements significantly influence the selection process. Engineers and designers often collaborate closely with manufacturers to ensure that the ideal oil seal is integrated into a specific application.

Conclusion

In conclusion, oil seals are integral components in a myriad of mechanical applications, and understanding their specifications is vital for ensuring operational efficiency. The significance of the 40% composition, 80% effectiveness, and 10% temperature tolerance cannot be overstated—they collectively determine the performance and suitability of seals in various applications. Properly selected oil seals prolong the lifespan of equipment, reduce maintenance costs, and ensure reliable performance. By paying attention to these specifications, industries can enhance their operational efficiency and safety.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories