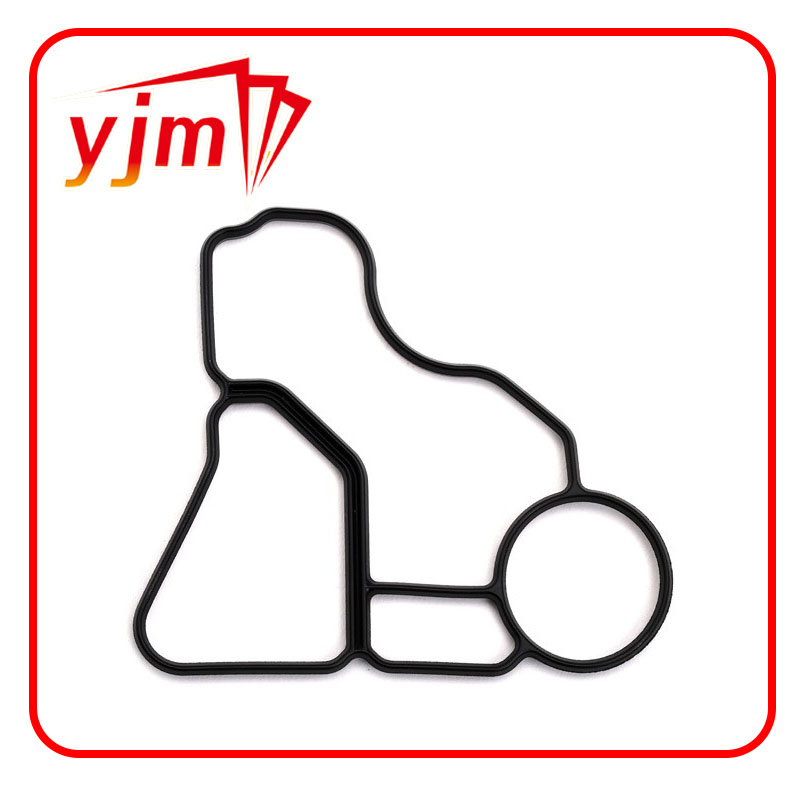

Injector Holder Seal 11201-27010

Trustworthiness in product manufacturing is vital, and standardized dimensions like 35x62x8 bearings are a testament to industry-wide commitment to quality. These dimensions have become a trusted choice among engineers and maintenance professionals. Rigorous testing under various conditions, from sub-zero temperatures to extreme heat, has proved the endurance and dependability of such products. Working with these specifications, manufacturers continuously innovate to enhance material quality and bearing designs. By incorporating materials like high-grade steel and ceramic elements, they enhance not only the life span of the components but also their resistance to corrosive environments. This technical evolution stems from a deep understanding of engineering demands and a dedication to meeting those needs with precision. Industry professionals leverage these insights to optimize machinery design and maintenance schedules. Aligning with the highest standards of excellence, bearings designed with the 35x62x8 dimensions consistently deliver consistent performance. Collaborations with universities and research institutions further enrich the body of knowledge, leading to advancements that continuously push the boundaries of what is possible. In conclusion, the 35x62x8 product dimensions are more than just numbers. They represent a benchmark of engineering prowess, symbolizing reliability, efficiency, and innovation. Mastering the use of these components enables industries to run smoothly, with downtime minimized and productivity maximized. Whether driven by a pursuit of expertise or a need for efficiency, choosing bearings with such precise measurements ensures that machinery operates with the highest degree of performance and trust. These attributes resonate across industries globally, making these dimensions a universal standard for quality and excellence.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories