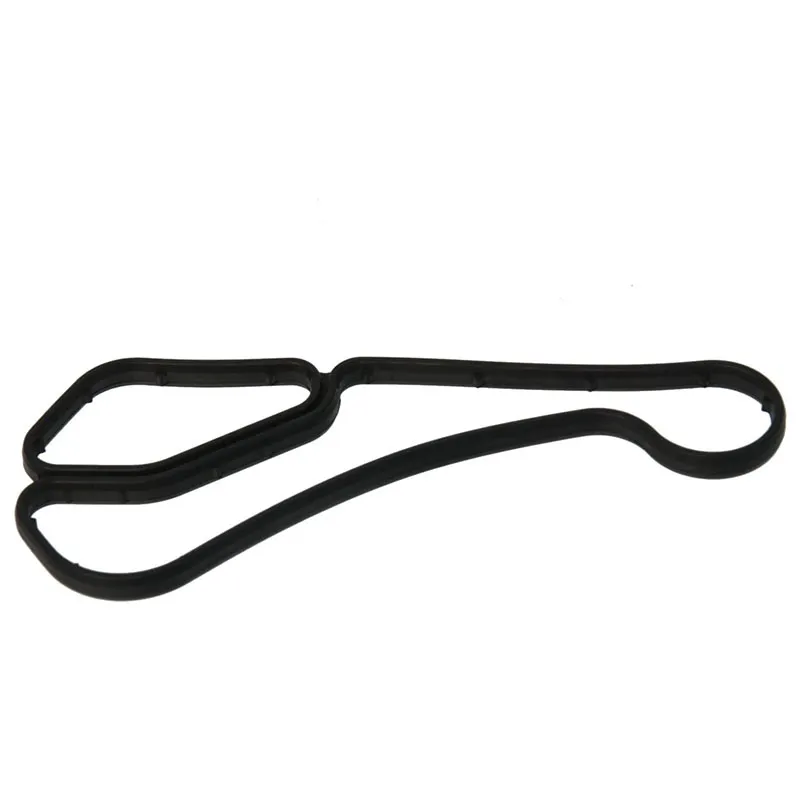

oil filter flange gasket

The Importance of Oil Filter Flange Gaskets in Engine Performance

In the intricate world of automotive engineering, every component has a significant role to play. Among these components, the oil filter flange gasket may not be the most glamorous, but it is undeniably crucial for the optimal performance of an engine. Understanding its purpose, materials, installation, and maintenance can greatly enhance vehicle performance and longevity.

What is an Oil Filter Flange Gasket?

An oil filter flange gasket is a sealing component positioned between the oil filter and its mounting surface on the engine. Its primary function is to create a tight seal that prevents motor oil from leaking out. Motor oil is essential in lubricating the engine's moving parts, reducing friction and wear while also providing cooling properties. A well-functioning gasket ensures that the oil remains contained within the engine, contributing to overall efficiency.

The Role of the Oil Filter Flange Gasket

1. Leak Prevention The most critical function of the oil filter flange gasket is to prevent oil leaks. If oil were to leak from this connection, it would not only lead to a loss of essential lubricating fluids but could also create a slew of mechanical problems ranging from reduced engine performance to severe damage, warranting costly repairs.

2. Contamination Protection A proper seal provided by the gasket helps keep contaminants out of the oil system. Dust, dirt, and other foreign particles can enter if there are gaps, leading to abrasive wear on engine components. This protection is vital for the vehicle’s longevity and reliability.

3. Pressure Maintenance The oil filter operates under high pressure, and a robust gasket ensures that this pressure is maintained. This is essential for optimal filtration and lubrication, which ultimately translates to better engine performance.

Materials Used in Oil Filter Flange Gaskets

Oil filter gaskets are made from various materials, each chosen for its properties that enhance durability and functionality

. Common materials include- Rubber Often used due to its flexibility and excellent sealing capabilities. Rubber gaskets can withstand heat and are resistant to oil degradation.

oil filter flange gasket

- Silicone This material provides superior temperature resistance and flexibility, making it ideal for high-performance engines.

- Composite Materials Some gaskets are made from composite materials that combine various substances to enhance strength and flexibility.

Choosing the right material is crucial in ensuring that the gasket performs effectively under the specific conditions of the automotive application.

Installation and Maintenance

Proper installation of the oil filter flange gasket is key to its effectiveness. Here are some installation tips

1. Clean the Surface Before installing a new gasket, ensure that the mounting surfaces are clean and free of old gasket material and debris. This prevents leaks and ensures a firm seal.

2. Follow Manufacturer Guidelines Always refer to the vehicle’s manual for specific instructions regarding torque specifications and installation procedures.

3. Inspect Regularly Gaskets should be inspected regularly. Look for signs of oil leaks, visible cracks, or wear. Replacing a damaged gasket promptly can prevent more severe engine issues.

Conclusion

In summary, while the oil filter flange gasket may appear to be a small and insignificant component, its role in vehicle performance is anything but trivial. By ensuring that oil remains contained, preventing contamination, and maintaining pressure within the oil system, this gasket significantly contributes to the overall health of an engine. Whether you’re a car enthusiast, a mechanic, or just someone who wants to understand more about vehicle maintenance, paying attention to the oil filter flange gasket can lead to better engine performance and a longer-lasting vehicle. Regular maintenance and timely replacement of this critical component can save considerable time and money in the long run, ensuring your vehicle runs smoothly for years to come.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories