The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

When it comes to maintaining a boat’s smooth operation and longevity, marine bearing systems play a crucial role. These specialized bearings are designed to withstand harsh marine environments, including constant exposure to water, salt, and varying loads.

One of the most common types of marine bearings is the cutlass bearing, sometimes spelled as cutless bearing. These bearings are primarily used to support the propeller shaft in boats, ensuring it spins freely and smoothly while resisting corrosion and wear.

The cutlass bearing boat setup is critical because it absorbs lateral and axial loads from the propeller shaft, keeping the shaft aligned and reducing vibration. Without a properly functioning cutlass bearing, the shaft may wobble, leading to increased wear, potential damage to the propeller, and inefficient engine performance.

Why marine bearings are essential:

Provide smooth rotation for the propeller shaft

Absorb shock and vibration caused by water resistance

Resist corrosion from saltwater and marine debris

Extend the life of the propulsion system

Using high-quality marine bearings ensures safer and more efficient boating.

Boat Trailer Wheel Bearings: Maintenance and Replacement Tips

Just as your boat relies on marine bearings, the trailer transporting it depends heavily on boat trailer wheel bearings. These bearings allow the wheels of your trailer to rotate smoothly, making it easier and safer to tow your boat over land.

Boat trailer wheel bearings endure a lot of stress from road conditions, heavy loads, and exposure to water and dirt, especially if you frequently launch your boat from ramps or in saltwater environments. Over time, these bearings can wear out, corrode, or fail, leading to noisy wheels, uneven wear, or even dangerous trailer wheel lockups.

Key maintenance tips for boat trailer wheel bearings:

Regularly inspect for signs of wear, noise, or grease leakage

Clean and repack the bearings with marine-grade grease at least once a season

Replace worn or damaged bearings promptly to prevent wheel damage

Use seals and bearing protectors to keep water and debris out

Proper care of your boat trailer wheel bearings can prevent costly repairs and ensure your boat arrives safely every time.

Cutlass Bearings: Why They’re Vital for Your Boat’s Performance

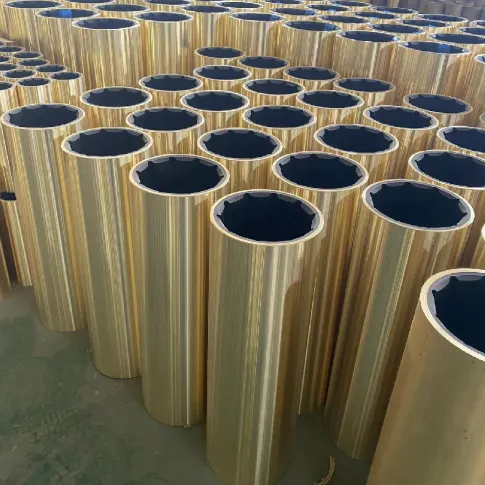

The cutlass bearing, also known as the cutless bearing, is a rubber-lined bearing that cushions the propeller shaft, making it one of the most important components in a boat’s drivetrain.

Originally designed by the Cutlass Rubber Company, these bearings consist of a brass or bronze shell with a flexible rubber lining that allows the bearing to absorb shock and accommodate slight misalignments of the shaft. This design makes the cutlass bearing boat setup highly effective in rough water conditions.

Replacing your cutlass bearings at recommended intervals is vital because worn bearings can cause shaft misalignment, leading to excessive vibration, shaft wear, and damage to other drivetrain components.

Signs you may need new cutlass bearings:

Excessive propeller shaft movement or vibration

Unusual noises near the stern of the boat

Reduced engine performance or fuel efficiency

Visible corrosion or wear upon inspection

Using quality cutlass bearings and maintaining them properly extends the life of your boat’s propulsion system and enhances overall performance on the water.

Keep Your Boat Running Smoothly with Proper Bearing Care

Whether it’s the essential marine bearings supporting your propeller shaft or the boat trailer wheel bearings ensuring safe transport, regular maintenance and timely replacement of bearings are critical for any boat owner. The specialized cutlass bearing boat system protects your propeller shaft from damage and keeps your vessel running efficiently.

By understanding the role of each type of bearing, recognizing signs of wear, and using quality parts, you can avoid costly repairs and enjoy worry-free boating for years to come.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

Νέα Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

Νέα Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

Νέα Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

Νέα Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

Νέα Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

Νέα Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

Νέα Nov.22,2025

Κατηγορίες προϊόντων