Understanding Shaft Seals in Stuffing Boxes for Enhanced Equipment Performance

Understanding Stuffing Box Shaft Seals Essential Components of Rotational Equipment

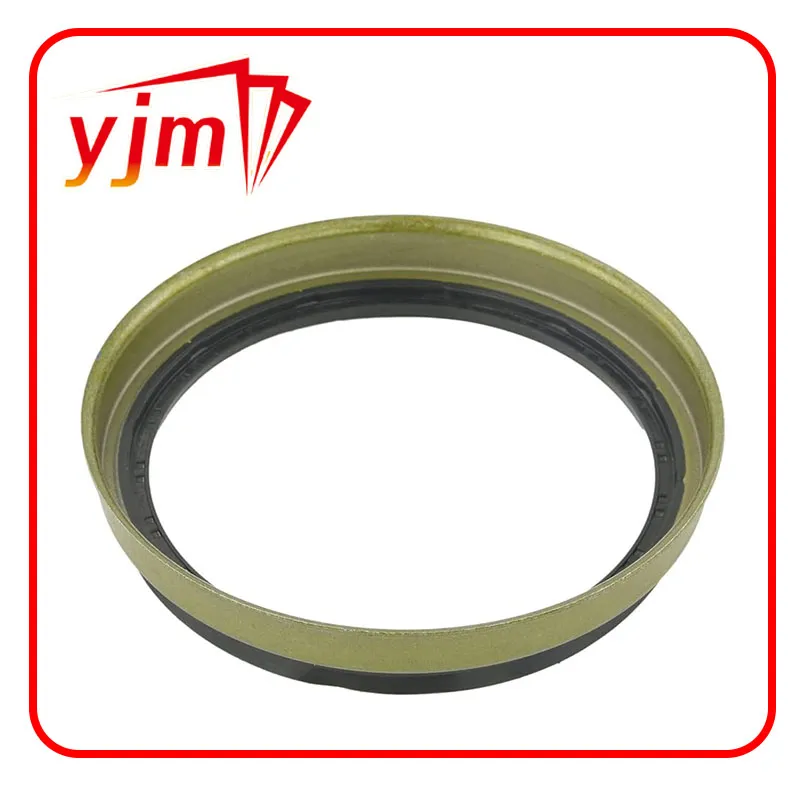

Stuffing box shaft seals play a critical role in the operation of rotating machinery across various industries, including oil and gas, chemical processing, and water treatment. These seals serve as a barrier to prevent the leakage of fluids, thereby protecting the integrity of the machinery and the environment. Understanding their function, design, and maintenance is essential for ensuring efficient and reliable operation.

Function of Stuffing Box Shaft Seals

The primary function of a stuffing box shaft seal is to contain lubricants or process fluids within the equipment while allowing for the rotation of a shaft. This is especially crucial in applications where the media being contained can be hazardous or where leakage can lead to operational inefficiencies. By preventing leaks, stuffing box seals help improve safety and maintain the required pressure levels within the machinery.

Design Components

A typical stuffing box assembly consists of several components, including the stuffing box itself, packing materials, a gland, and a shaft. The stuffing box is essentially a cylindrical chamber that accommodates packing materials, which are usually made from materials such as graphite, PTFE (Polytetrafluoroethylene), or rubber. These packing materials are designed to compress against the shaft, forming a seal that can withstand varying degrees of pressure and temperature.

The gland holds the packing materials in place and applies the necessary pressure to create an effective seal. Proper alignment of the shaft and stuffing box is critical to avoid excessive wear on the packing materials, which can lead to leaks and reduced performance.

Types of Stuffing Box Seals

There are several types of stuffing box seals, each designed for specific applications

. The most common types include1. Traditional Packing Seals These are made from braided materials, which provide good sealing capabilities. They are often used in applications with lower rotational speeds and pressures.

stuffing box shaft seal

2. Mechanical Seals These are more advanced than traditional packing seals and are generally used in high-speed or high-pressure applications. Mechanical seals consist of two flat surfaces that are pressed together to prevent leakage.

3. Lip Seals Often used for rotary applications, lip seals have a lip that contacts the shaft, forming a barrier against leakage. They are commonly used in hydraulic systems and pumps.

Maintenance and Best Practices

Regular maintenance of stuffing box shaft seals is crucial to ensure their longevity and effectiveness. Here are some best practices

- Regular Inspection Routine checks for wear and tear can help identify issues before they lead to significant problems. Look for signs of leakage, which can indicate that the packing material may need to be replaced.

- Shaft Alignment Ensure that the shaft is properly aligned to minimize wear on the packing material. Misalignment can lead to uneven pressure on the seal, exacerbating leakage.

- Proper Lubrication Adequate lubrication reduces friction between the shaft and the packing material, extending the life of the seal.

- Replacement of Packing Over time, packing material can become compressed or worn out. Regularly replace packing materials as needed, based on the manufacturer's recommendations and operating conditions.

Conclusion

In conclusion, stuffing box shaft seals are vital components in the machinery that require protection from leakage. Their design, function, and maintenance are crucial for the efficient operation of many industrial processes. By understanding and implementing best practices for stuffing box seals, organizations can enhance the reliability of their equipment, minimize environmental impact, and ensure safety in their operations. Regular inspections, proper alignment, and timely replacements are essential strategies to maintain optimal performance and longevity of these seals.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories