Understanding the Functionality and Applications of Lip Seal Rings in Machinery

Understanding Lip Seal Rings A Comprehensive Overview

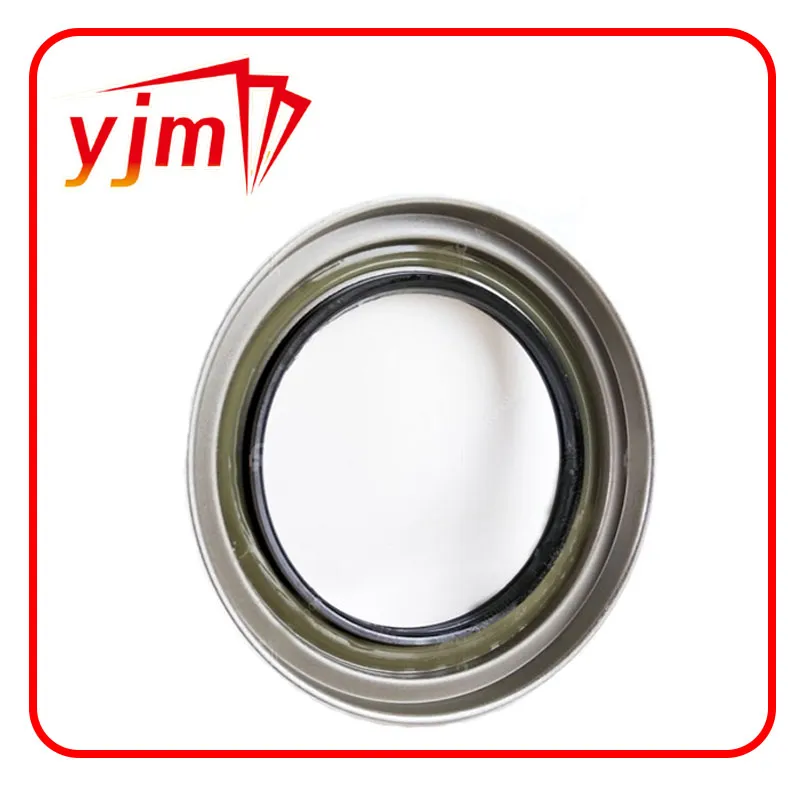

Lip seal rings are critical components used in various mechanical applications to prevent fluid leakage and contamination. These seals are particularly important in industries such as automotive, aerospace, and manufacturing, where maintaining the integrity of mechanical systems is crucial. This article will explore the construction, types, applications, and advantages of lip seal rings, highlighting their significance in engineering and industrial settings.

What are Lip Seal Rings?

Lip seal rings, commonly referred to simply as lip seals, are specialized sealing devices designed to separate moving parts from the environment while preventing the escape of lubricant or other fluids. They are typically made from elastomeric materials, such as rubber, and feature a flexible lip that conforms to the surface of the shaft or bore, creating a tight seal. This design allows lip seals to withstand high pressures and temperatures, making them suitable for various demanding applications.

Construction of Lip Seal Rings

The construction of a lip seal ring typically includes several key components

1. Body The main body of the seal, which provides structural stability and is often made of a durable elastomer or plastic. 2. Lip The flexible extension that contacts the sealing surface. It can be single or double-lipped, depending on the sealing requirements. 3. Spring Many lip seals incorporate a spring to maintain contact pressure against the shaft, enhancing sealing performance. 4. Metal casing Some designs include a metal casing for added strength and durability, particularly in high-pressure applications.

The material selection for lip seals is critical, as it affects the seal's performance, life span, and ability to resist environmental factors such as temperature, chemical exposure, and wear.

Types of Lip Seal Rings

There are several different types of lip seals available, each designed for specific applications

lip seal ring

1. Static Lip Seals Used in applications where there is little or no relative motion between the sealing surfaces, such as in hydraulic cylinders. 2. Dynamic Lip Seals Designed to accommodate relative motion, these seals are common in rotating shafts, such as those found in motors and pumps. 3. Double Lip Seals Featuring two lips, these seals provide added protection against the ingress of contaminants and the escape of fluids. 4. Heavy-duty Lip Seals Often used in extreme conditions, these seals are designed for harsher environments and can handle larger fluctuations in pressure and temperature.

Applications of Lip Seal Rings

Lip seal rings are versatile and widely used across various industries

- Automotive In vehicles, lip seals are found in engines, gearboxes, and differential assemblies, where they prevent oil leaks and protect components from external contaminants. - Aerospace Aircraft rely on lip seals to function effectively in hydraulic systems and engines, where reliability and safety are paramount. - Manufacturing In machines and equipment, lip seals help maintain lubrication within bearings and gears, extending the life of the machine and preventing downtime.

Advantages of Lip Seal Rings

Lip seals offer numerous advantages that make them a preferred choice for many applications

1. Effective Sealing The unique design of lip seals provides excellent sealing capabilities, effectively preventing leaks and contamination. 2. Low Friction Lip seals are designed to minimize friction between moving parts, allowing for smoother operation and improved energy efficiency. 3. Cost-Effective Compared to other sealing solutions, lip seals are generally more economical, providing cost savings during both manufacturing and maintenance. 4. Versatility The ability to customize lip seals for specific applications makes them suitable for a wide variety of industrial and commercial uses.

Conclusion

Lip seal rings play an essential role in the integrity and efficiency of many mechanical systems. Their unique design, combined with the advantages they offer, make them a vital component in a range of industries. As technology continues to advance, the development of new materials and designs for lip seals will further enhance their effectiveness and application scope, ensuring they remain a crucial element in modern engineering solutions. Understanding their function and benefits is essential for anyone involved in mechanical design, maintenance, or manufacturing.

-

Understanding Cassette Seals: A Durable Solution for Oil and Dirt Protection

News Apr.30,2025

-

Understanding and Maintaining the Polaris Ranger Front Differential

News Apr.30,2025

-

Understanding and Maintaining the Polaris Front Differential

News Apr.30,2025

-

Understanding and Maintaining the Crank Oil Seal for Engine Efficiency

News Apr.30,2025

-

Heavy Duty Seals: Durable Solutions for Home, Industrial, And Commercial Use

News Apr.30,2025

-

Auto Oil Seals: Protecting Your Engine from Leaks and Contamination

News Apr.30,2025

-

Essential Tools and Kits Every Car Owner Should Have

News Apr.29,2025

Products categories