Exploring the Benefits and Applications of O-Ring Face Seals in Industries

Understanding O-Ring Face Seals Benefits and Applications

O-ring face seals are integral components widely used in various industries for their efficiency and reliability in preventing fluid leakage. These seals are designed to create a tight barrier between two mating surfaces, ensuring that no fluids escape from the system. In this article, we will explore the design, advantages, and applications of O-ring face seals, providing insights into why they are a preferred choice for many engineering applications.

Design and Functionality

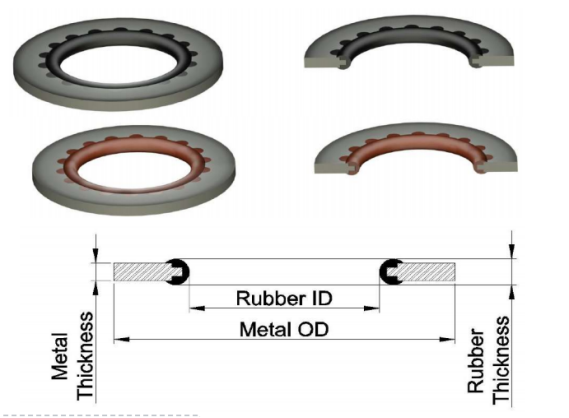

O-ring face seals consist of two main components an O-ring and a mating surface. The O-ring is typically made from elastomeric materials, such as rubber or silicone, which provide flexibility and resilience. When compressed between two surfaces, the O-ring expands to fill any gaps, creating a secure seal that effectively prevents the escape of liquids or gases.

The design of O-ring face seals allows them to operate in different environments, including high pressure and temperature scenarios. Their resilience makes them suitable for various fluids, including oil, water, and chemicals. Depending on the application, O-rings can be manufactured in different sizes, shapes, and hardness levels to meet specific sealing requirements.

Advantages of O-Ring Face Seals

1. Cost-Effective O-ring face seals are relatively inexpensive compared to other sealing solutions. Their simple design reduces manufacturing complexity and costs, making them a go-to option for many applications.

2. Ease of Installation O-rings are easy to install and do not require specialized tools or techniques. This simplicity allows for faster assembly and maintenance, reducing downtime in industrial settings.

3. Versatility O-ring face seals can be used in a vast array of applications, from automotive systems to aerospace components. Their adaptability to various conditions makes them an ideal choice across different sectors.

4. Reliable Performance The sealing capability of O-ring face seals minimizes the risk of leakage, which can lead to operational inefficiencies and environmental concerns. This reliability is crucial in applications where fluid containment is vital.

o ring face seal

5. Long Service Life When properly installed and maintained, O-ring face seals can provide a long service life, which reduces the frequency of replacements and associated costs.

Applications

O-ring face seals are used in numerous industries, including

- Automotive In the automotive sector, O-ring face seals are used in engines, hydraulic systems, and fuel systems. They help ensure that fluids remain contained within the system, preventing leaks and optimizing performance.

- Aerospace The aerospace industry relies on O-ring face seals for various applications, including fuel systems and hydraulic actuators. The need for high-performance sealing solutions in extreme conditions makes O-rings an ideal choice.

- Oil and Gas In the oil and gas sector, O-ring face seals are critical for maintaining pressure in pipelines and equipment. Their ability to withstand harsh environments and chemicals makes them suitable for these demanding applications.

- Manufacturing O-ring face seals are widely utilized in various manufacturing processes, where they are used to seal pumps, valves, and other critical components that require leak-proof performance.

Conclusion

O-ring face seals play a vital role in ensuring the efficiency and reliability of various systems across multiple industries. Their simple yet effective design, combined with their cost-effectiveness and versatility, makes them a preferred sealing solution for engineers and manufacturers alike. As industries continue to evolve and demand higher performance, the O-ring face seal will undoubtedly remain a crucial component for achieving effective fluid containment and preventing unwanted leakage. Understanding their design, advantages, and applications can empower professionals to make informed decisions about which sealing solutions best meet their operational needs.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories