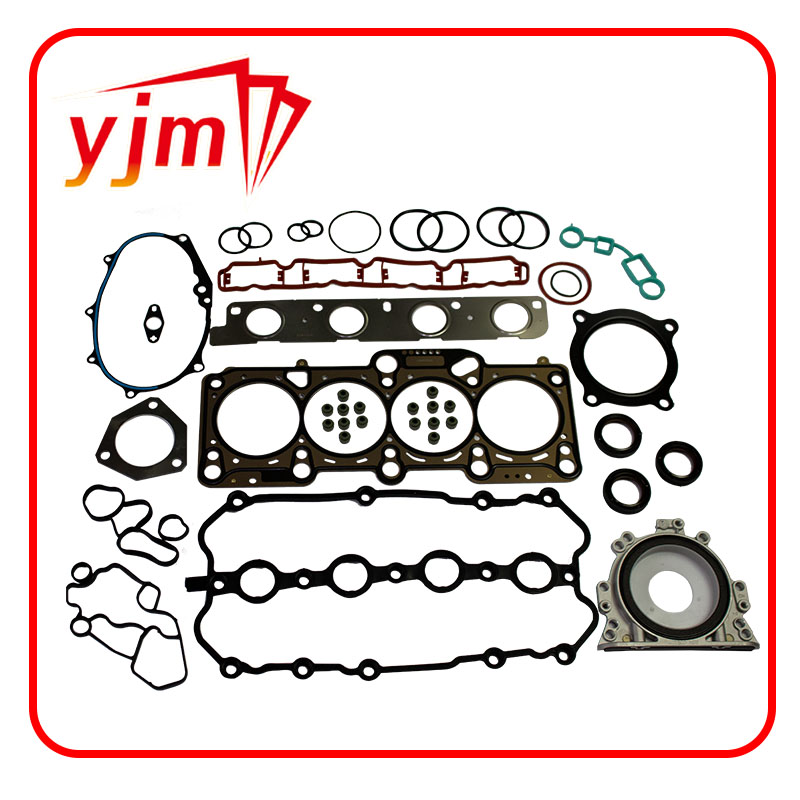

Non-Metallic Flat Gasket - High-Performance Sealing Solutions

Non-Metallic Flat Gaskets An Overview

Non-metallic flat gaskets are essential components used in various industrial applications to ensure a leak-proof seal between two mating surfaces. These gaskets are primarily composed of non-metallic materials, which offer several advantages over their metallic counterparts. Understanding the characteristics, applications, and benefits of non-metallic flat gaskets is crucial for industries that rely on reliable sealing solutions.

Materials and Manufacturing

Non-metallic flat gaskets are made from a diverse range of materials, including rubber,PTFE (polytetrafluoroethylene), cork, and various types of fiber. Each material provides distinct properties that cater to specific applications. For instance, rubber gaskets are known for their flexibility and good sealing capacity under compressive stress, making them ideal for low-pressure applications. PTFE gaskets, on the other hand, are renowned for their chemical resistance and high-temperature tolerance. This makes them suitable for use in industries where aggressive chemicals or extreme temperatures are prevalent.

The manufacturing process of non-metallic flat gaskets typically involves cutting the gasket shapes from sheets of the chosen material. Precision cutting techniques, including die cutting and water jet cutting, are often employed to ensure accurate dimensions and surface finishes. These methods help maintain the integrity of the gasket material, ensuring optimal performance.

Applications

non metallic flat gasket

Non-metallic flat gaskets find applications across a wide range of industries, including automotive, chemical processing, oil and gas, food and beverage, and more. In the automotive sector, they are commonly used in engine assemblies, oil pans, and transmission covers. In chemical processing, these gaskets provide a reliable seal for pipes, tanks, and valves, preventing leaks of hazardous substances. Moreover, in food and beverage applications, non-metallic gaskets ensure compliance with sanitary requirements while providing a secure seal that prevents contamination.

Advantages

One of the primary benefits of non-metallic flat gaskets is their ability to conform to irregular surfaces, ensuring a tight seal. This flexibility helps to absorb vibrations and thermal expansion, allowing the gasket to maintain its sealing integrity over time. Additionally, non-metallic gaskets are often lighter and easier to install than metallic alternatives, reducing labor costs and installation time.

Furthermore, the variety of materials available allows for customization based on specific environmental conditions. Industries can choose gaskets that are resistant to chemicals, oils, and temperature fluctuations, ensuring longevity and reduced maintenance needs.

Conclusion

In summary, non-metallic flat gaskets play a critical role in ensuring effective sealing in numerous industrial applications. Their diverse materials, manufacturing methods, and adaptability to various environments make them indispensable in maintaining operational efficiency and preventing leaks. As industries continue to evolve, the demand for reliable sealing solutions such as non-metallic flat gaskets will remain vital, supporting the integrity and safety of countless systems and processes.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories