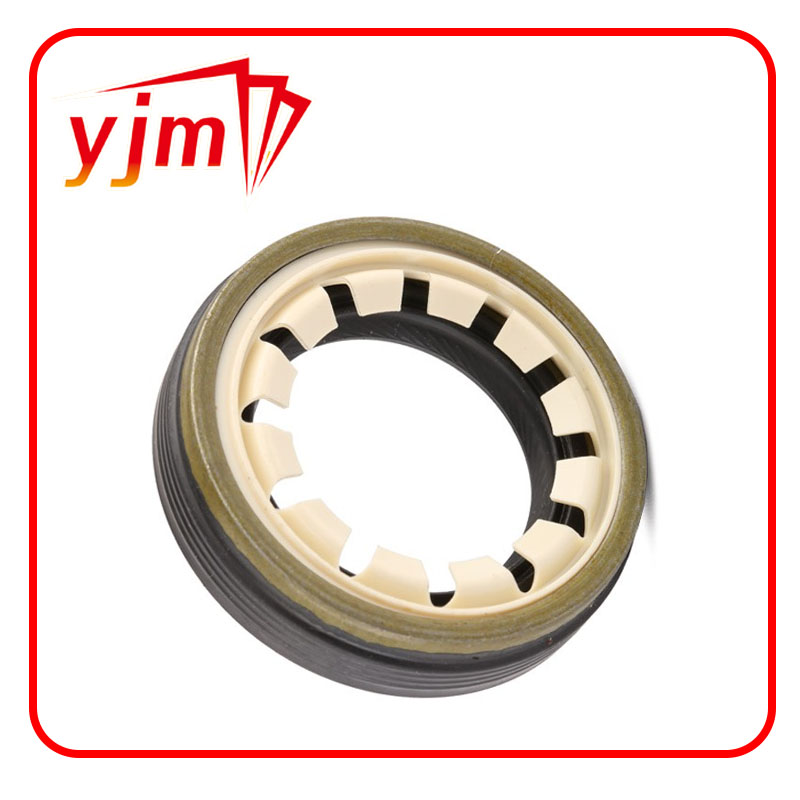

backup rings

The Concept of Backup Rings Enhancing Reliability in Sealing Solutions

In the world of engineering and manufacturing, ensuring the integrity of seals in various applications is paramount. One innovative solution that has gained traction is the use of backup rings. These components play a crucial role in enhancing the reliability and longevity of seals in a wide range of industries, from aerospace to automotive, and even in industrial machinery.

A backup ring is a supportive component that is placed alongside an O-ring seal. Its primary function is to prevent the O-ring from extruding or deforming under high pressure or extreme conditions. When a seal is subjected to significant differential pressure, the O-ring can be forced out of its groove, leading to leaks and equipment failure. The introduction of backup rings mitigates this risk, ensuring that the seal remains intact and effective even under challenging circumstances.

Backup rings are typically made from materials with high resilience and resistance to wear, such as polyurethane, PTFE (Teflon), or various elastomers. The choice of material depends largely on the specific application and the environmental conditions the seal will face. For instance, in high-temperature applications, a material that can withstand heat while maintaining its mechanical properties is essential. Similarly, in corrosive environments, materials must be selected based on their chemical compatibility.

backup rings

There are two primary types of backup rings solid and split. Solid backup rings provide continuous support along the entire circumference of the O-ring, making them suitable for applications where the risk of extrusion is high. Split backup rings, on the other hand, are designed to facilitate easier installation and maintenance. They can be easier to align and replace without disassembling entire systems, which is a significant advantage in high-maintenance industries.

The application of backup rings extends beyond merely preventing leaks. They contribute to the overall efficiency of systems by maintaining the integrity of seals under fluctuating pressures and temperatures. This reliability is critical in applications such as hydraulic systems, where even a minor failure can lead to catastrophic results. For instance, in aerospace technology, where every component must function flawlessly, backup rings provide an additional layer of security against potential seal failures.

In summary, backup rings are vital components that enhance the performance and reliability of sealing systems across various industries. By preventing the extrusion of O-rings in high-pressure applications, they ensure consistent operation and longevity of machinery. The thoughtful selection of materials and types of backup rings tailored to specific applications can make a significant difference in operational efficiency and safety. As industries continue to evolve, the importance of innovations like backup rings will only grow, underscoring the need for reliable sealing solutions in an increasingly demanding technological landscape.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories