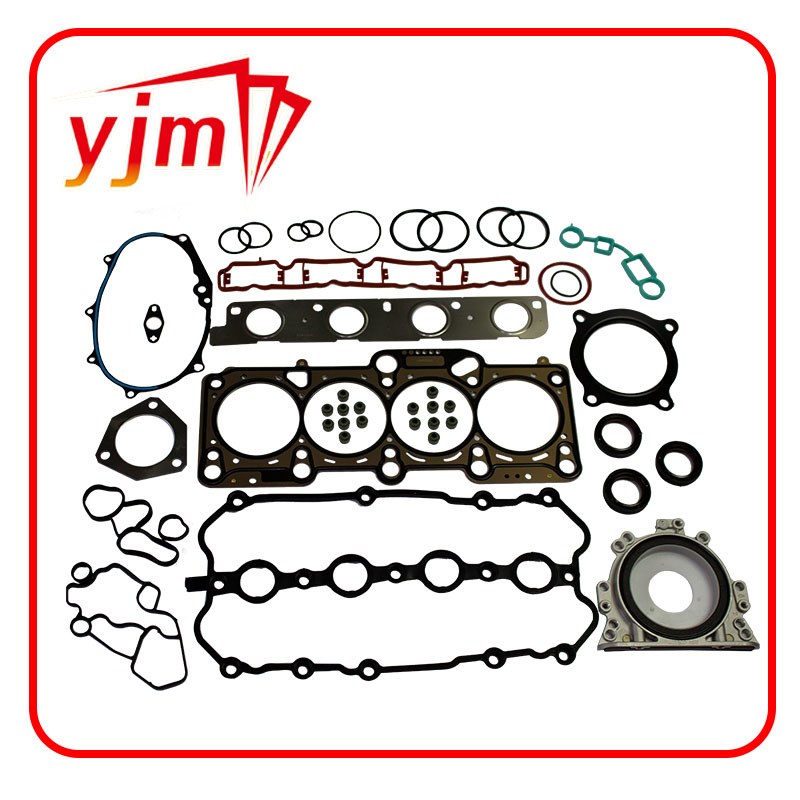

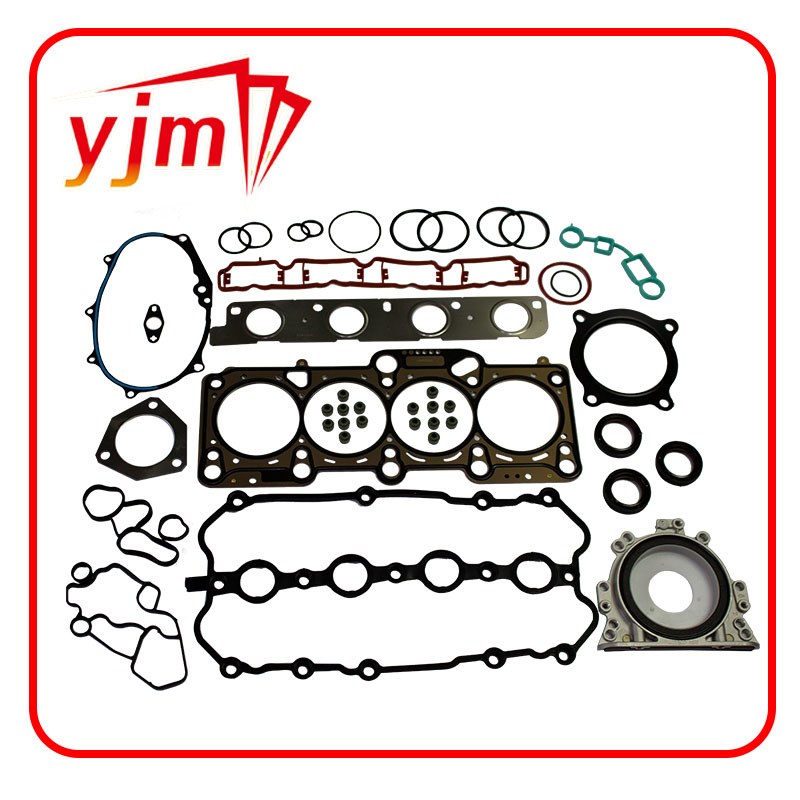

Oil seal & rubber products

The importance of oil seals and rubber products extends beyond their immediate function

The importance of oil seals and rubber products extends beyond their immediate function

The importance of oil seals and rubber products extends beyond their immediate function

The importance of oil seals and rubber products extends beyond their immediate function oil seal & rubber products. They play a critical role in maintaining the cleanliness and integrity of critical fluids within machinery. By preventing leaks and contamination, these components help to extend the life of equipment, reduce maintenance costs, and minimize downtime. In addition, the proper selection and maintenance of oil seals and rubber products can also contribute to improved energy efficiency and reduced environmental impact.

In conclusion, oil seals and rubber products are essential components of modern machinery and equipment. Their ability to provide reliable sealing and protection under a variety of conditions is crucial to the smooth operation and long-term success of any system. As technology continues to advance and industries become more dependent on precision machinery, the importance of these components will only continue to grow. It is therefore essential that engineers, maintenance personnel, and manufacturers understand the role of oil seals and rubber products in their respective fields and work to ensure their proper selection, installation, and maintenance.

oil seal & rubber products. They play a critical role in maintaining the cleanliness and integrity of critical fluids within machinery. By preventing leaks and contamination, these components help to extend the life of equipment, reduce maintenance costs, and minimize downtime. In addition, the proper selection and maintenance of oil seals and rubber products can also contribute to improved energy efficiency and reduced environmental impact.

In conclusion, oil seals and rubber products are essential components of modern machinery and equipment. Their ability to provide reliable sealing and protection under a variety of conditions is crucial to the smooth operation and long-term success of any system. As technology continues to advance and industries become more dependent on precision machinery, the importance of these components will only continue to grow. It is therefore essential that engineers, maintenance personnel, and manufacturers understand the role of oil seals and rubber products in their respective fields and work to ensure their proper selection, installation, and maintenance. -

The Ultimate Guide to Building a Car Repair Kit Every Driver Should Own

News May.09,2025

-

The Essential Guide to Oil Filter Gaskets and Housings in Engine Maintenance

News May.09,2025

-

The Complete Guide to Oil Pan Gaskets for Honda B-Series and Automatic Transmissions

News May.09,2025

-

How to Identify and Repair Oil Housing Gasket and Seal Leaks

News May.09,2025

-

Everything You Need to Know About Oil Pan Gaskets and Replacements

News May.09,2025

-

Everything You Need to Know About Changing Oil Filter and Adapter Gaskets

News May.09,2025

-

Understanding Marine Bearings: The Key to Smooth Sailing and Safe Trailering

News May.08,2025

Products categories