Reliable Lip Seal Suppliers - High Quality Sealing Solutions

Understanding Lip Seal Suppliers The Backbone of Industrial Sealing Solutions

In the vast landscape of manufacturing and industrial operations, the importance of effective sealing solutions cannot be overstated. Among the many types of seals available, lip seals have gained a prominent position due to their reliability, durability, and efficiency. This article explores the role of lip seal suppliers in providing high-quality sealing solutions tailored to various industry needs.

Lip seals, also known as radial shaft seals or rotary seals, are designed to retain lubrication while preventing the ingress of dirt, dust, and contaminants. Commonly used in applications such as automotive, aerospace, and industrial machinery, these seals play a critical role in ensuring the smooth operation of moving parts. However, the effectiveness of a lip seal heavily depends on the quality and performance of the seal itself, which is where specialized suppliers come into play.

Lip seal suppliers are essential partners for manufacturers across numerous sectors. They provide a wide range of products that are engineered to meet specific requirements, ensuring that clients receive seals that are not only suitable for their applications but also offer longevity and performance. Suppliers often work closely with their clients to understand the unique challenges they face, allowing them to recommend the most effective sealing solutions.

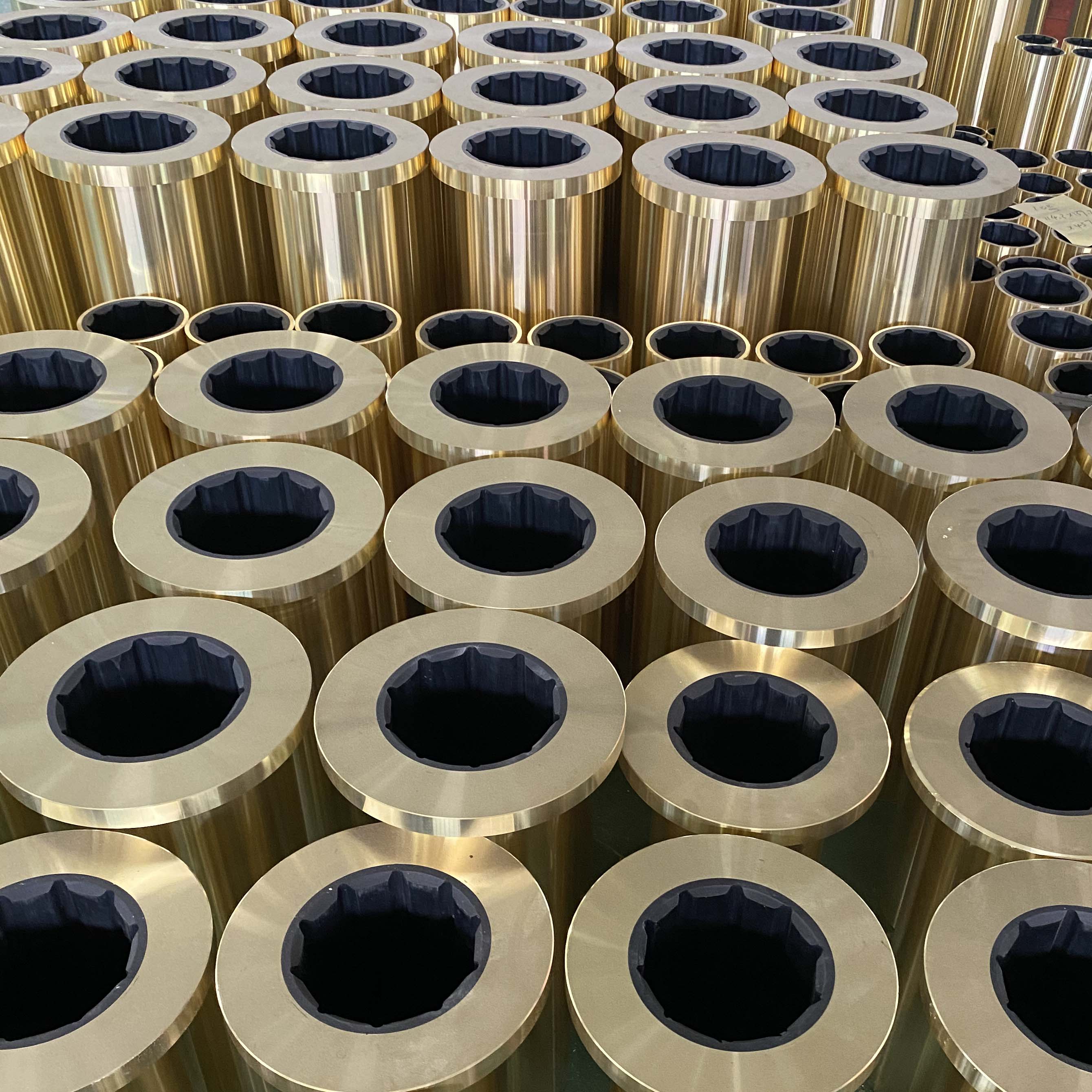

lip seal suppliers

One of the key attributes of reputable lip seal suppliers is their commitment to innovation. The sealing industry is consistently evolving, with advancements in materials and technologies leading to improved seal performance. Suppliers that stay at the forefront of these developments can offer their customers cutting-edge solutions that enhance operational efficiency and reduce maintenance costs. For instance, advancements in synthetic materials and specially designed profiles can lead to better wear resistance and lower friction, resulting in a longer lifespan for the seals.

Moreover, reputable lip seal suppliers typically adhere to strict quality control standards. This ensures that every product dispatched meets industry benchmarks and customer expectations. Many suppliers obtain certifications such as ISO, which reflects their commitment to quality management and continuous improvement. This emphasis on quality is vital, as failures in sealing can lead to costly downtime and repairs.

Additionally, strategic partnerships between manufacturers and lip seal suppliers can lead to customized solutions that cater specifically to unique application requirements. Custom lip seals can be designed to specific sizes, shapes, or materials, providing a tailored approach that enhances operational efficiency.

In conclusion, lip seal suppliers are pivotal in the industrial landscape, offering high-quality sealing solutions that meet the diverse needs of various sectors. Their commitment to quality, innovation, and customization not only ensures optimal performance but also plays a significant role in enhancing the longevity and reliability of machinery. As industries continue to evolve, the role of lip seal suppliers will undoubtedly remain crucial in driving efficiency and effectiveness in operations across the board.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories